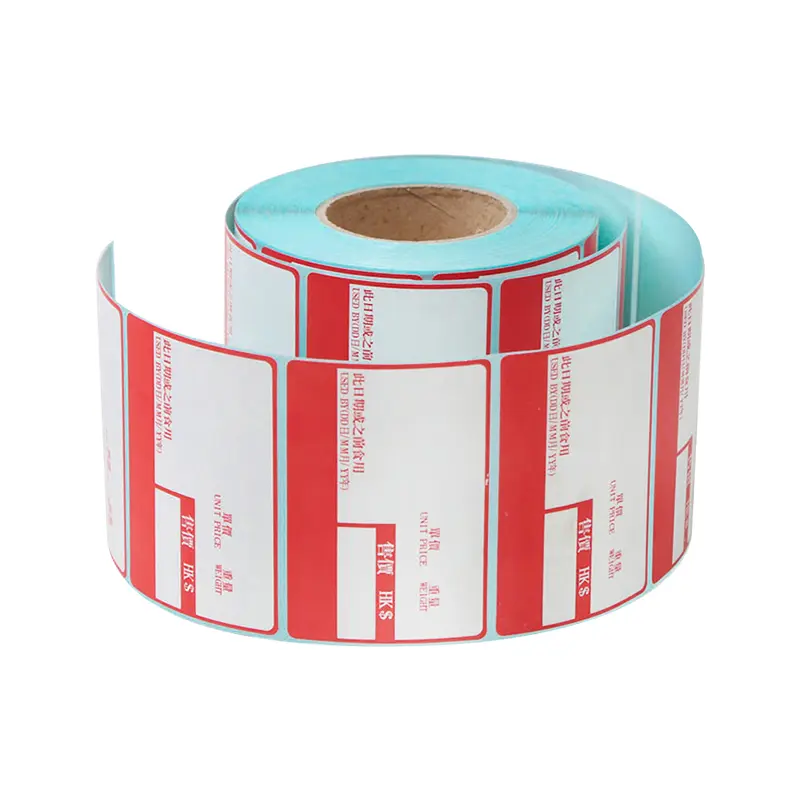

High-Quality Thermal Transfer Barcode Labels | Trusted Brand for Reliable Solutions

Premium thermal transfer barcode labels that offer exceptional print quality and durability are available at competitive prices. Ideal for retail, logistics, and manufacturing, these labels provide clear, scannable prints for efficient tracking. Made from high-quality materials, they ensure longevity and performance even in demanding environments. At ShenZhen Sailing Paper Co., Ltd., flexible order quantities and quick shipping options cater to your business needs. Choose our thermal transfer barcode labels for a reliable, cost-effective solution to keep your operations running efficiently.

Methods To Barcode Labels Thermal Transfer Manufacturer Factory

Sailing, established in 2011, has significantly evolved into a prominent international group dedicated to the production and export of printing, packaging, and logistic consumables. With manufacturing facilities in both China and Malaysia, we have streamlined our operations to meet the growing demand for high-quality barcode labels. As a thermal transfer manufacturer, we understand the importance of delivering durable and efficient labeling solutions that cater to various industries, from retail to logistics.

Our barcode labels are designed using advanced thermal transfer technology, ensuring that every label produced meets strict quality standards. This method not only enhances readability but also improves the longevity of the labels, making them suitable for diverse applications. By sourcing materials locally and employing skilled labor, we can offer competitive pricing without compromising on quality. We pride ourselves on our customer-centric approach, providing tailored solutions and quick turnaround times to our global partners.

Sailing’s commitment to innovation and quality has positioned us as a reliable choice for businesses seeking efficient labeling solutions. By partnering with us, you’ll gain access to an extensive product range and the expertise needed to enhance your operational efficiency. Whether you are a small business or a large corporation, our team is dedicated to supporting your needs and helping you navigate the complexities of logistics and packaging in today’s dynamic market.

Methods To Barcode Labels Thermal Transfer Manufacturer Factory

| Method | Description | Advantages | Disadvantages | Suitable For |

|---|---|---|---|---|

| Direct Thermal | Uses heat-sensitive paper with a printhead. | No ink or ribbon required, lower costs. | Limited durability, sensitive to heat. | Shipping labels, receipts. |

| Thermal Transfer | Uses a ribbon that melts on the label material. | High durability, produces high-quality prints. | Higher costs due to ribbon and maintenance. | Product labeling, asset tracking. |

| Laser Printing | Uses laser technology to print on labels. | Fast printing speeds, excellent print quality. | Initial investment is high, toner costs. | High-volume printing environments. |

| Inkjet Printing | Sprays ink onto label material. | Vibrant colors and images, low initial cost. | Ink can smudge or run, slower than other methods. | Specialty labels, promotional items. |

| Flexographic Printing | Uses flexible relief plates to transfer ink. | Great for large runs, ideal for colorful designs. | High setup costs, not economical for small runs. | Food packaging, labels for beverages. |

Why Barcode Labels Thermal Transfer Delivers Unmatched Quality Service Backed by Expertise

J

James Thompson

The quality of this product exceeded my expectations. The team provided outstanding support throughout the purchasing process.

08

June

2025

Z

Zoe Mitchell

I love this product! The support team showed great understanding and professionalism throughout.

24

June

2025

E

Ella Williams

I’m impressed! The product quality and after-sales support crew were both top-notch.

11

June

2025

S

Sophia Reed

Fantastic purchase! The product is of high quality, and their service team is very professional.

07

June

2025

S

Samuel Reed

Amazing purchase! The product quality is true to description, and the service was professional and helpful.

13

June

2025

A

Ava Young

Fantastic quality! I truly appreciate the professionalism of their customer service team.

24

June

2025

Thermal labels

Thermal labels