Best Explosive Material Labels Guide: Top OEMs, Companies, and Exporters

When it comes to labeling explosive materials, quality and compliance are paramount. That's why I rely on the Best Explosive Material Label from ShenZhen Sailing Paper Co., Ltd. These high-quality labels not only adhere to strict safety regulations but also provide clear and effective communication for your products. For B2B companies, dependable labeling is essential for compliance and ensuring safe handling practices. Our labels are crafted from sturdy materials designed to endure harsh conditions, ensuring that vital information remains visible and intact. With customizable options and meticulous attention to detail, you can trust that these labels will meet your specific requirements. If safety and quality are priorities in your operations, the Best Explosive Material Label is a wise investment that you can depend on for your business needs.

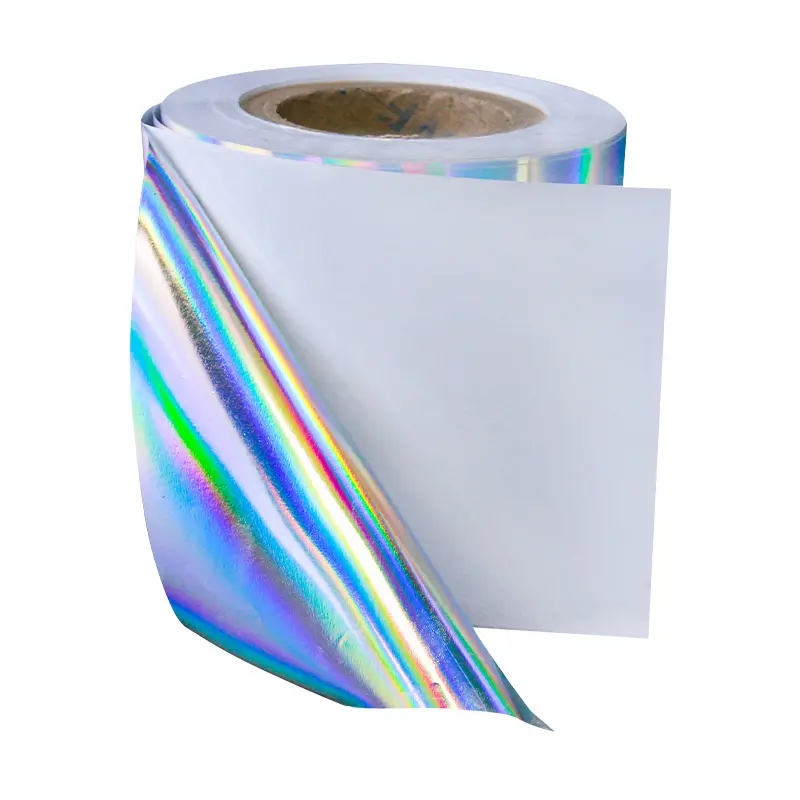

7 Key Tips To Best Explosive Material Label Application Supplies the World’s Top Brands

In an increasingly competitive marketplace, the right labeling supplies can significantly impact your brand’s visibility and compliance, especially for products involving explosive materials. At Sailing, we understand the unique challenges faced by international brands in this sector. Since our founding in 2011, we have transformed from a local paper converter into a globally recognized enterprise, with production facilities in both China and Malaysia. Our experience positions us to provide exceptional quality and reliability in printing, packaging, and logistics consumables tailored specifically for explosive materials.

Here are seven key tips to ensure your label application meets the highest standards. First, prioritize compliance with international regulations and safety standards to avoid costly penalties. Second, choose durable materials resistant to moisture, chemicals, and extreme temperatures to ensure longevity and visibility. Third, employ advanced printing techniques for legibility, including clear fonts and contrasting colors, to enhance safety and compliance. Fourth, ensure your labels are adaptable for various surfaces — whether for containers, pallets, or storage units. Fifth, integrate tamper-evident features that protect your brand integrity. Sixth, consider sustainability in your label supplies to appeal to eco-conscious consumers. Lastly, work with a reliable supplier like Sailing who understands the nuances of the explosive materials industry to streamline your procurement process and ensure consistent quality across all products. By implementing these strategies, you can effectively boost your brand’s reputation while maintaining stringent safety standards.

7 Key Tips To Best Explosive Material Label Application Supplies the World’s Top Brands

| Tip Number | Key Tip | Recommended Material | Application Method | Durability |

|---|---|---|---|---|

| 1 | Use High-Visibility Colors | Vinyl | Digital Printing | 5+ Years |

| 2 | Ensure Weather Resistance | Polyester | Heat Transfer | 3-5 Years |

| 3 | Select the Right Adhesive | Waterproof Paper | Self-Adhesive | 2-3 Years |

| 4 | Incorporate Clear Icons | Laminated Vinyl | Silkscreen | 7+ Years |

| 5 | Follow Regulatory Standards | Reflective Material | Vinyl Cutting | 5+ Years |

| 6 | Consider Size & Compatibility | BOPP | Die-Cut | 4-6 Years |

| 7 | Regularly Inspect and Update Labels | Weatherproof Labels | Digital Printing | 3 Years |

Practical Strategies for Best Explosive Material Label Where Innovation Meets 2025 More Than a Supplier - A Partner

E

Emma Johnson

Excellent craftsmanship! I truly appreciate the prompt and professional service from the support team.

14

June

2025

S

Samantha Wright

The craftsmanship is outstanding. I felt valued as a customer due to their exceptional after-sales service.

13

May

2025

N

Natalie Turner

Great purchase! The quality is excellent and the service staff is incredibly professional.

17

May

2025

C

Carter Rivera

Great product! The after-sales service was really efficient and professionally handled.

22

June

2025

S

Sophia Reed

Fantastic purchase! The product is of high quality, and their service team is very professional.

07

June

2025

H

Henry Adams

Exceptional quality! Their team responded promptly to my inquiries, showcasing great professionalism.

23

June

2025

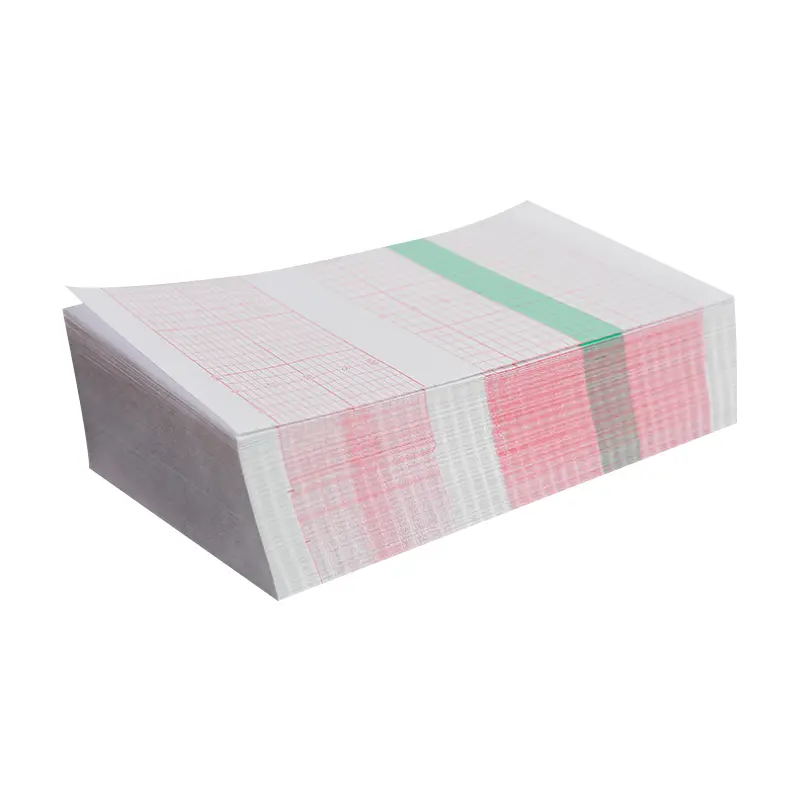

Thermal labels

Thermal labels