Bopp Material Insights for ODM Exporters and Suppliers: A Comprehensive Guide

Bopp materials are essential for B2B purchasers seeking cost-effective solutions without compromising on quality. Our offerings provide exceptional durability and performance, making them perfect for optimizing production processes. With a comprehensive pricelist, you can easily find products tailored to your specific needs. At ShenZhen Sailing Paper Co., Ltd., we prioritize transparency and are committed to delivering high-quality materials and support to help you achieve your production goals efficiently.

How To Decide Between Bopp Material Definition Now Trending Guarantees Peak Performance

In today's competitive market, selecting the right materials for your packaging and printing needs is crucial for ensuring peak performance and customer satisfaction. One material that has gained prominence in recent years is BOPP (Biaxially Oriented Polypropylene). As global procurement professionals, you may be faced with the decision of whether BOPP is the right choice for your products. Understanding its definition and advantages can provide valuable insights.

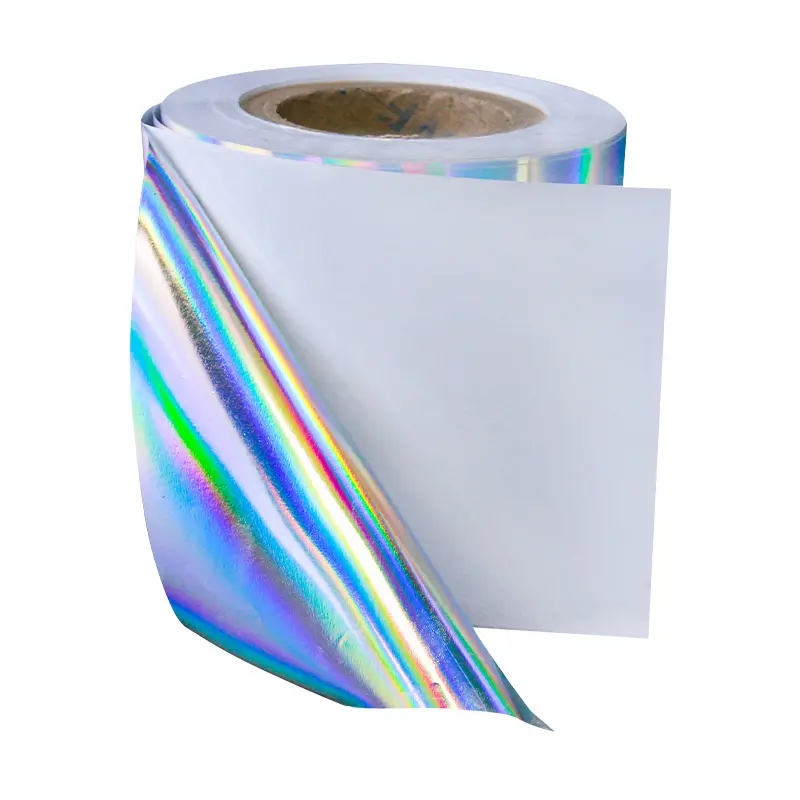

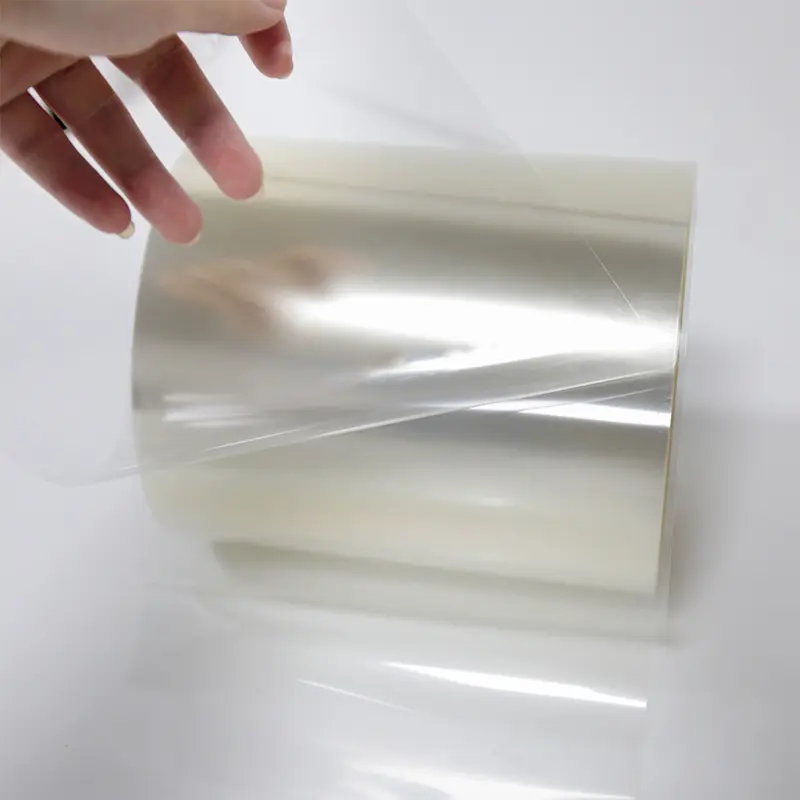

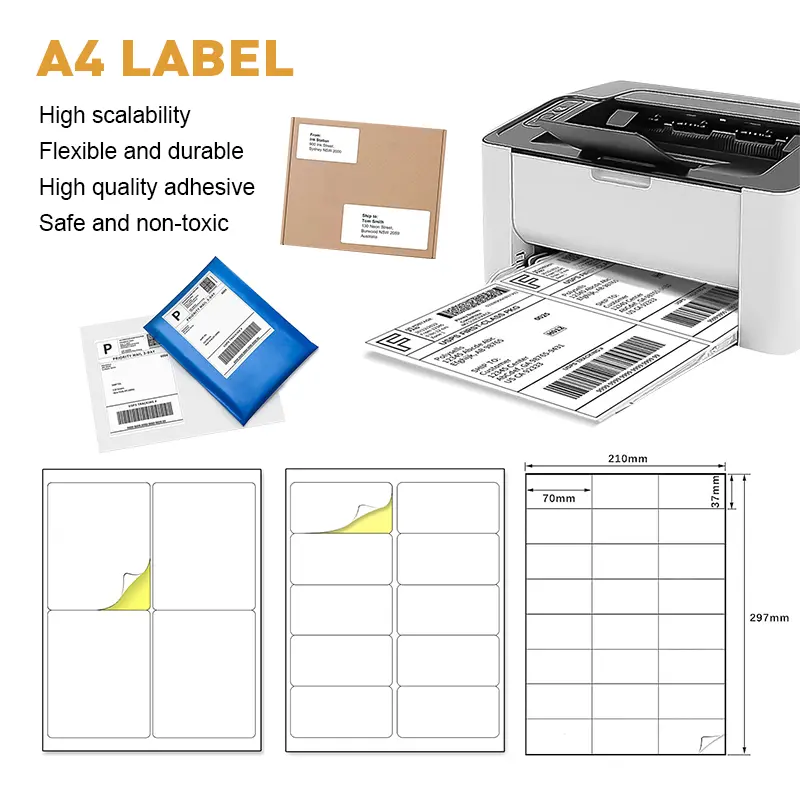

BOPP is a versatile, flexible, and durable plastic film known for its excellent clarity, tensile strength, and resistance to moisture and chemicals. Its ability to retain print quality makes it a popular choice for labels, packaging, and various other applications. With the global demand for sustainable and high-performance materials on the rise, BOPP is increasingly favored for its recyclability and cost-effectiveness. At Sailing, we have dedicated ourselves to producing and exporting high-quality BOPP materials, leveraging our advanced facilities in China and Malaysia. Since our inception in 2011, we have become recognized as a trusted player in the packaging industry, providing solutions that meet our clients' unique needs.

When contemplating the use of BOPP, consider factors such as the specific performance requirements of your application, cost implications, and sustainability goals. Partnering with experienced suppliers like Sailing can ensure you receive expert advice tailored to your business needs. Our commitment to quality and innovation enables us to deliver top-tier BOPP products that guarantee excellent performance and help you stay ahead in the market.

How To Decide Between Bopp Material Definition Now Trending Guarantees Peak Performance

| Attribute | BOPP Characteristics | Applications | Performance Metrics |

|---|---|---|---|

| Thickness | 12µm - 100µm | Packaging, Labels | Tensile Strength: 35 MPa |

| Clarity | High Transparency | Food Packaging, Decorative Films | Haze: |

| Chemical Resistance | Good | Protective Films, Adhesive Tapes | Solvent Resistance: High |

| Printability | Good on Various Inks | Labels, Wrapping Materials | Ink Adhesion: Excellent |

| Environmental Impact | Recyclable | Sustainable Packaging Solutions | Waste Reduction: Effective |

How To Pick The Right Bopp Material Definition Delivers Unmatched Quality Supplies the World’s Top Brands

M

Mia Hernandez

Absolutely satisfied with my purchase! The staff’s knowledge and care in service were remarkable.

23

May

2025

Z

Zoe Mitchell

I love this product! The support team showed great understanding and professionalism throughout.

24

June

2025

S

Sebastian Baker

Impressive product quality! The team provided exemplary service with thorough responses.

13

June

2025

L

Lucy Thompson

I am extremely satisfied! The service staff displayed remarkable professionalism and skill.

02

July

2025

N

Noah Lewis

Awesome product quality! The support team offered thorough and professional assistance.

11

June

2025

E

Ethan Scott

Quality is exceptional! Support team handled my concerns with utmost professionalism.

22

June

2025

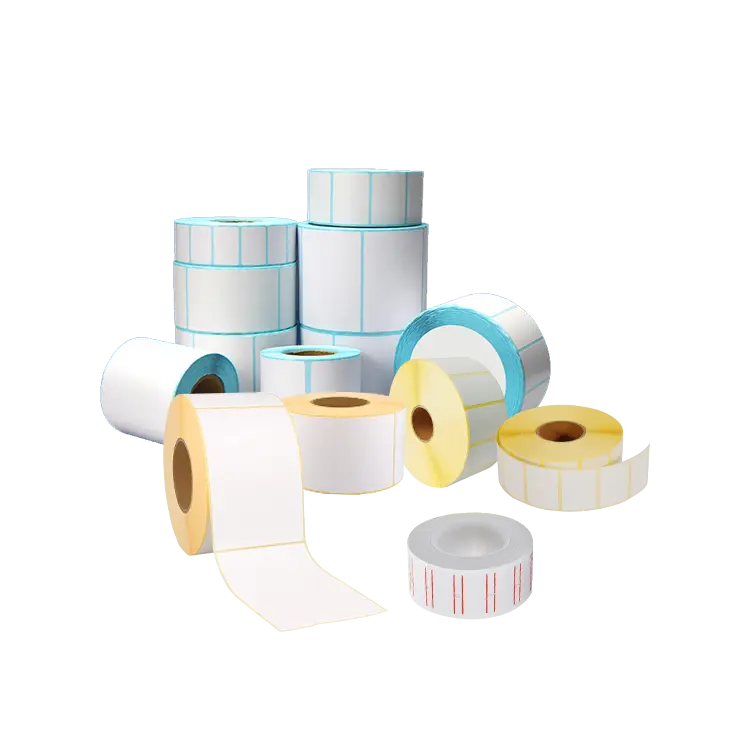

Thermal labels

Thermal labels