Top Bopp Roll Labels Manufacturers: Buyer Tips & Quotes for Best Choices

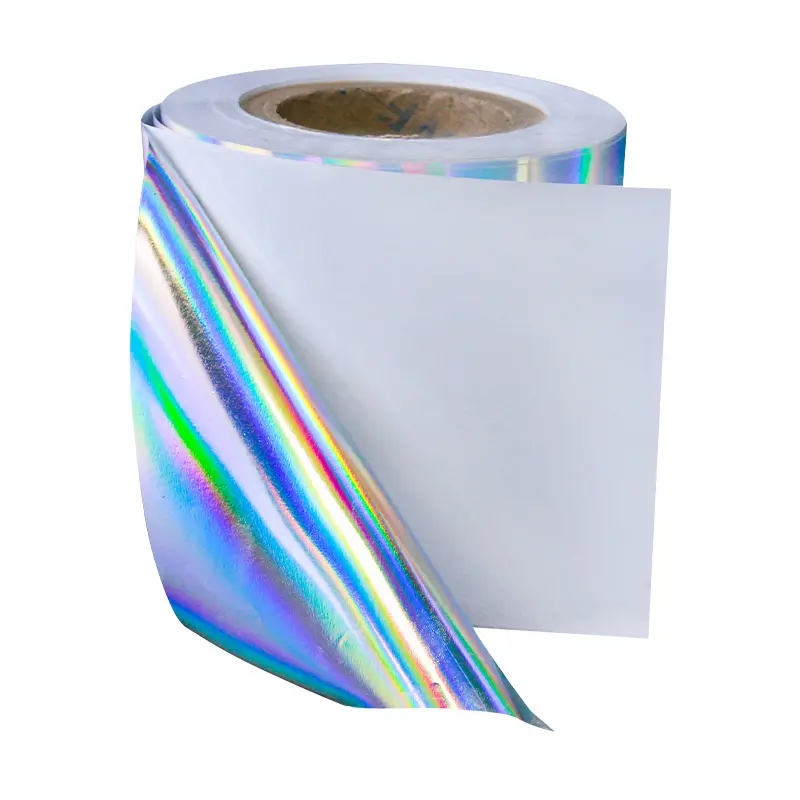

Premium BOPP roll labels offer exceptional reliability and durability for various business applications. Engineered to endure diverse conditions, our labels ensure strong adhesion and excellent clarity. At ShenZhen Sailing Paper Co., Ltd., we leverage high-quality materials and cutting-edge printing technology to produce labels that adhere to the highest industry standards. Ideal for the food, beverage, and retail sectors, our customizable BOPP roll labels can be tailored to meet your specific branding requirements.

Expert Tips For bopp roll labels From Concept to Delivery Factory-Direct Excellence

When it comes to sourcing high-quality BOPP roll labels, understanding the journey from concept to delivery is crucial for global buyers. At Sailing, we have transformed from a local paper converter since our inception in 2011 into a respected international group with state-of-the-art production facilities in China and Malaysia. Our focus on printing, packaging, and logistics consumables ensures that our clients receive factory-direct excellence, minimizing costs while maximizing quality.

To create outstanding BOPP roll labels, the process begins with a clear design concept. Engage with our expert team to explore materials, finishes, and printing techniques that will best represent your brand and meet your specific requirements. With extensive experience in the industry, we advise on optimal choices to ensure durability and aesthetic appeal, ultimately enhancing your product’s market potential.

Once the design is finalized, our seamless production process kicks in. We utilize advanced technology and stringent quality control measures, ensuring that every label meets international standards. Our commitment to sustainability and efficiency reflects in our manufacturing practices, allowing us to deliver high-quality products rapidly. Partner with Sailing, and experience how our dedicated service and expertise can elevate your labeling solutions from concept to delivery, securing your position in the competitive global market.

Expert Tips For BOPP Roll Labels From Concept to Delivery Factory-Direct Excellence

| Tip | Description | Benefit | Example |

|---|---|---|---|

| Choose the Right Material | Selecting BOPP for its durability and resistance to moisture. | Increases label lifespan and maintains appearance. | Ideal for products exposed to refrigeration. |

| Optimize Artwork | Use high-resolution images and vibrant colors to enhance visibility. | Draws attention to your product on the shelf. | Bright and eye-catching designs lead to higher sales. |

| Consider Labelling Regulations | Ensure that your labels comply with local laws and standards. | Avoids legal issues and enhances brand trust. | Nutrition facts and ingredient lists on food packaging. |

| Test Print Before Full Production | Print a sample to assess colors and material performance. | Ensures the final product meets expectations. | Review before committing to large quantities. |

| Utilize Factory-Direct Services | Work directly with manufacturers for better pricing and communication. | Saves money and streamlines the process. | Direct collaboration enhances project efficiency. |

Must-Choose Reasons bopp roll labels Your End-to-End Solution More Than a Supplier - A Partner

C

Christopher Lee

Fantastic product! The support team demonstrated a high level of professionalism and expertise.

12

June

2025

H

Harper King

Great quality and performance! The team was professional, making the whole process seamless.

30

June

2025

H

Henry Evans

Excellent craftsmanship! I had a smooth experience with their competent support team.

25

June

2025

A

Alexander Hughes

Such great quality! Their customer service team made the whole process effortless.

18

June

2025

M

Michael Brooks

High-quality product! The support team was knowledgeable and extremely helpful.

27

May

2025

A

Andrew Mitchell

A fantastic product! The staff was knowledgeable and provided excellent service.

17

June

2025

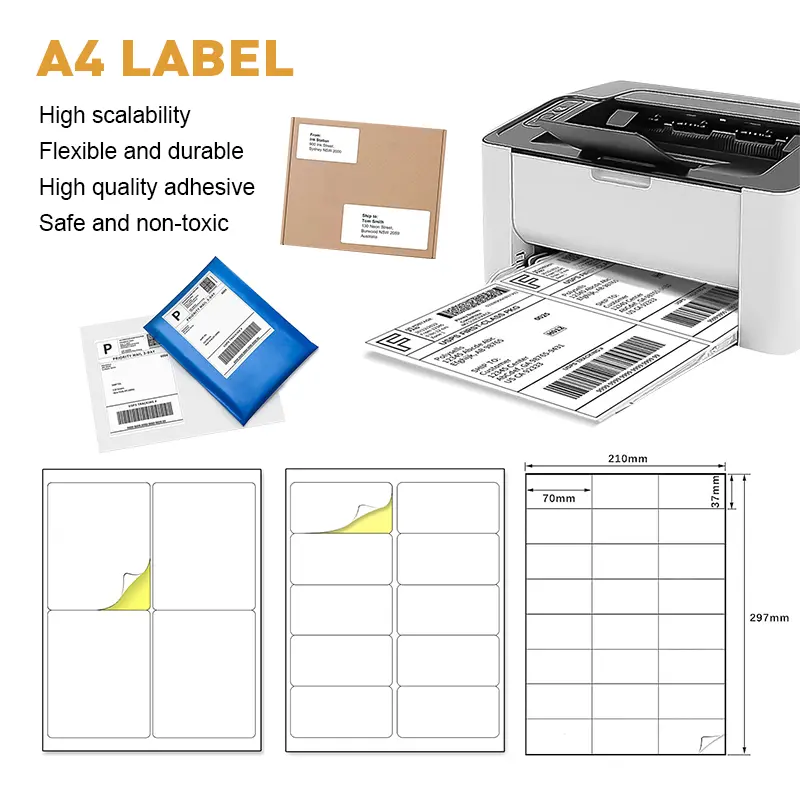

Thermal labels

Thermal labels