Best China Thermal Paper Slitting Rewinding Machine Factory & Exporter

Looking for the best China thermal paper slitting rewinding machine? You've come to the right place! As a leading exporter and manufacturer, we pride ourselves on delivering high-quality machines that meet the diverse needs of our clients. Our advanced technology ensures precision slitting and rewinding, enhancing your production efficiency, Rest assured, when you choose our machines, you’re not just purchasing equipment; you’re investing in a partner who cares about your success. Let's work together to enhance your operational capabilities and achieve your business goals with our top-notch thermal paper slitting rewinding machines

7 Key Tips To China Thermal Paper Slitting Rewinding Machine Factory From Concept to Delivery Supplier

When you're looking to partner with a reliable supplier for thermal paper slitting rewinding machines, it's essential to understand the process from concept to delivery. Since its inception in 2011, Sailing has transformed from a local paper converter to an international group with production facilities in China and Malaysia. Our dedication to high-quality manufacturing and export of printing, packaging, and logistics consumables positions us as a leader in this industry.

Firstly, collaborating with a factory like Sailing means you can expect a comprehensive approach that covers everything from initial design concepts to final delivery. We value transparent communication and exact specifications to ensure that the machines meet your needs, whether you're in retail, logistics, or any other sector requiring thermal paper solutions. Our cutting-edge technology and experienced workforce contribute to producing machines that are not only efficient but also reliable, enhancing your operational productivity.

Lastly, quality assurance is paramount. Sailing adheres to strict quality control measures throughout the manufacturing process, ensuring that every machine delivered is of the highest standard. Our commitment to continuous improvement and innovation means that you, as a global purchaser, can trust us to provide not just products, but solutions that enhance your business operations. Choose Sailing for your thermal paper slitting rewinding machine needs and experience a seamless journey from concept to delivery.

7 Key Tips To China Thermal Paper Slitting Rewinding Machine Factory From Concept to Delivery Supplier

| Tip | Description | Key Considerations | Expected Outcomes |

|---|---|---|---|

| Tip 1 | Define requirements clearly to ensure the machine meets your needs. | Detailed specifications and performance metrics. | Reduced revisions and faster production timelines. |

| Tip 2 | Research potential suppliers thoroughly. | Check reviews, certifications, and past projects. | Higher likelihood of a reliable partnership. |

| Tip 3 | Request prototype or demo machine. | Evaluate machine performance before finalizing the order. | Informed decision-making based on hands-on experience. |

| Tip 4 | Negotiate pricing and payment terms upfront. | Discuss payment schedules, deposits, and warranties. | Clear financial expectations and budget control. |

| Tip 5 | Ensure compliance with local regulations. | Familiarize yourself with industry standards and regulations. | Avoid legal issues and ensure machine readiness. |

| Tip 6 | Establish a communication plan. | Set protocols for project updates and feedback loops. | Smooth collaboration and timely issue resolution. |

| Tip 7 | Plan for installation and training. | Arrange for on-site support during machine setup. | Maximize machine efficiency from day one. |

Best Methods To China Thermal Paper Slitting Rewinding Machine Factory Now Trending in 2025

S

Samantha Wright

The craftsmanship is outstanding. I felt valued as a customer due to their exceptional after-sales service.

13

May

2025

J

Jacob Gonzalez

This product delivers on quality! The after-sales support was knowledgeable and efficient.

25

May

2025

J

Jameson Harris

Great value for the quality! The service team was highly skilled and attentive to my needs.

10

June

2025

I

Isaac Phillips

Fantastic quality! The customer service was attentive and very knowledgeable.

31

May

2025

L

Lily Torres

Superb quality! Customer support was prompt and professional, making the buying process easy.

31

May

2025

I

Isabella Johnson

Thrilled with my order! The quality is excellent, and the staff’s professionalism is outstanding.

29

June

2025

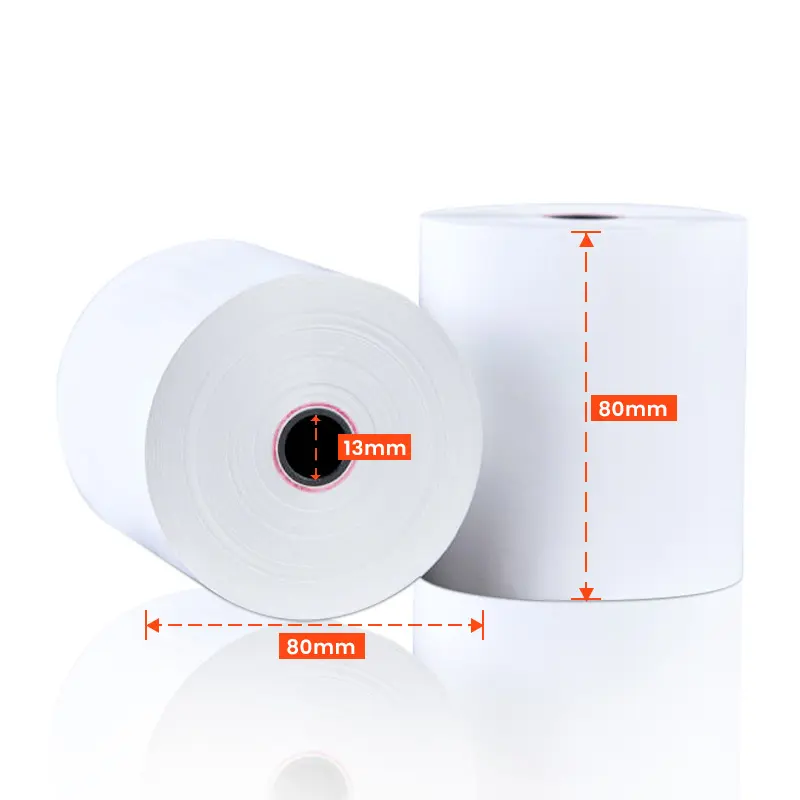

Thermal labels

Thermal labels