Wholesale Thermal Transfer Polypropylene Labels from Leading China Supplier & Exporter

Enhance your labeling needs with our high-quality China Thermal Transfer Polypropylene Labels. Designed for durability and clarity, these labels resist fading over time, making them ideal for various applications across retail, logistics, and manufacturing. At ShenZhen Sailing Paper Co., Ltd., we pride ourselves on delivering exceptional products that provide excellent value without compromising quality. By partnering with us, you can expect superior service, fast delivery, and reliable solutions tailored to meet your business requirements. Choose our labels to ensure your products make an impact. Contact us today to find out how our China Thermal Transfer Polypropylene Labels can support your success.

10 Essential Tips For China Thermal Transfer Polypropylene Labels Delivers Unmatched Quality Exceeds Industry Benchmarks

When it comes to sourcing premium thermal transfer polypropylene labels, quality is paramount. At Sailing, established in 2011, our transformation from a local paper converter to an international powerhouse, with production facilities in China and Malaysia, underscores our commitment to excellence. Here are ten essential tips for ensuring your polypropylene labels not only meet but exceed industry benchmarks.

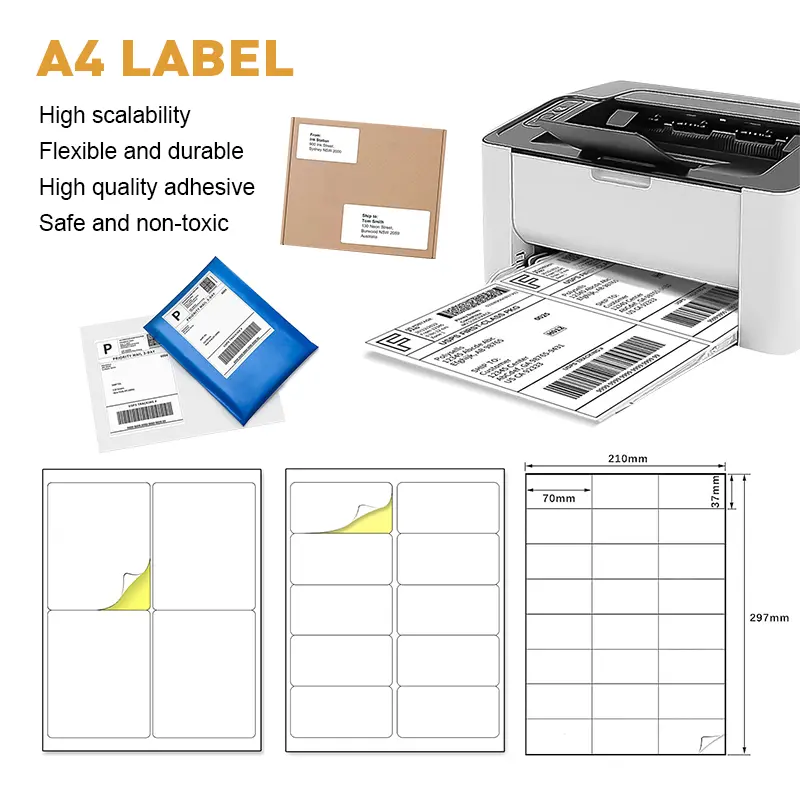

First, selecting the right adhesives is crucial. Advanced adhesive technology ensures strong bonding on various surfaces, enhancing durability in different environments. Second, consider the thermal transfer printing method. Our labels are engineered for compatibility with the latest printers, which guarantees crisp images and barcodes every time. Additionally, high-quality raw materials are vital. By utilizing superior polypropylene substrates, we achieve excellent resistance to moisture, UV light, and chemicals.

Finally, maintaining a stringent quality control process is indispensable. At Sailing, we implement rigorous inspections at every production stage, ensuring that our labels consistently deliver unmatched performance. By following these tips, global buyers can secure thermal transfer polypropylene labels that not only meet their operational needs but also reflect the highest standards of quality. Partner with Sailing for a seamless experience and outstanding results in your label requirements.

10 Essential Tips For China Thermal Transfer Polypropylene Labels Delivers Unmatched Quality Exceeds Industry Benchmarks

| Tip Number | Tip Title | Description | Benefit |

|---|---|---|---|

| 1 | Select Quality Materials | Use high-grade polypropylene to ensure durability. | Increases label lifespan and performance. |

| 2 | Consider Temperature Resistance | Choose labels that resist extreme temperature conditions. | Ensures labels remain legible in various environments. |

| 3 | Optimize Print Quality | Utilize thermal transfer printers for high-resolution output. | Enhances clarity and reduces misprints. |

| 4 | Use Appropriate Adhesives | Select adhesives based on application surfaces. | Increases adhesion strength and prevents label peeling. |

| 5 | Consider UV Resistance | Opt for UV-resistant labels to prevent fading. | Maintains label appearance over time. |

| 6 | Evaluate Flexibility | Choose flexible labels for curved surfaces. | Improves application on varied surfaces. |

| 7 | Inspect Print Durability | Test prints under different conditions for durability. | Ensures long-lasting prints. |

| 8 | Prioritize Cost-Effectiveness | Balance quality and price to maximize ROI. | Enhances overall budget management. |

| 9 | Maintain Consistent Quality Control | Implement regular quality checks in production. | Prevents defects and retains high standards. |

| 10 | Stay Updated on Regulations | Regularly review label material regulations. | Ensures compliance with industry standards. |

10 Essential Tips For China Thermal Transfer Polypropylene Labels Market Leader Exceeds Industry Benchmarks

L

Lucas Allen

Superior product quality! The customer service representatives were incredibly helpful and informative.

25

May

2025

M

Mason Carter

Exceptional product quality! The after-sales personnel were exemplary in their professionalism.

13

May

2025

N

Natalie Turner

Great purchase! The quality is excellent and the service staff is incredibly professional.

17

May

2025

H

Henry Williams

Top-notch quality! I appreciate how professional and prompt their service team has been.

03

June

2025

A

Addison Clark

I am thoroughly impressed! The product quality is fantastic and the service was impeccable.

06

June

2025

A

Ava Green

Quality and service both exceeded my expectations! The team was highly responsive and informative.

07

May

2025

Thermal labels

Thermal labels