Wholesale Color Printing on Thermal Labels from Top Factories

Looking for top-quality color printing on thermal labels? We specialize in producing high-performance thermal labels that meet your business needs. Our products are manufactured in factories that prioritize quality and efficiency. With CE certification, you can trust that our labels comply with international safety and quality standards, As exporters and suppliers, we take pride in providing exceptional service and reliable products. Our commitment to excellence means you’ll receive labels that not only enhance your branding but also perform reliably in various applications. Whether you’re in retail, logistics, or healthcare, we have the right thermal label solutions for you

10 Essential Tips For Color Printing On Thermal Labels Factories Your End-to-End Solution Trusted by Pros

Color printing on thermal labels has become an integral part of modern packaging and logistics. As a trusted partner for global buyers, Sailing understands the unique challenges faced by professionals in this field. With over a decade of experience since our establishment in 2011, we’ve evolved from a local paper converter to an international group with manufacturing facilities in both China and Malaysia. This transformation has allowed us to meet the growing demand for high-quality printing, packaging, and logistics consumables worldwide.

Here are ten essential tips for achieving excellent color printing on thermal labels that will elevate your products and ensure consistency throughout your branding. Firstly, always choose the right material; selecting thermal labels specifically designed for your printer type is crucial. Additionally, ensure your printer is calibrated to match your material for the best color accuracy. Regular maintenance of your printing equipment not only enhances longevity but also ensures optimal print quality. Furthermore, invest in high-quality inks that are known for their vibrancy and durability, as this will significantly impact the final output.

Finally, make use of design software to customize your labels precisely, testing designs with samples before mass production. By following these guidelines and leveraging our expertise at Sailing, you can trust that your color printing on thermal labels will not only meet expectations but exceed them, creating a lasting impact in the competitive landscape of packaging and logistics. Choose Sailing as your end-to-end solution and experience professional collaboration that drives success.

10 Essential Tips For Color Printing On Thermal Labels Factories Your End-to-End Solution Trusted by Pros

| Tip Number | Tip Description | Expected Outcome | Frequency of Use |

|---|---|---|---|

| 1 | Choose the right thermal label type. | Improved compatibility with printing technology. | Daily |

| 2 | Use high-quality ink for vibrant colors. | Better color accuracy and longevity. | Weekly |

| 3 | Calibrate your printer regularly. | Consistent print quality. | Monthly |

| 4 | Ensure proper label alignment. | Reduction in waste and misprints. | Each print job |

| 5 | Select the appropriate resolution settings. | Optimal print clarity. | Per print job |

| 6 | Perform regular maintenance on printers. | Prevent breakdowns and improve efficiency. | Bi-weekly |

| 7 | Test print settings prior to production runs. | Identify issues before large batches. | Each production run |

| 8 | Incorporate barcodes for tracking. | Enhanced inventory management. | Per label design |

| 9 | Utilize design software for label creation. | Professional appearance and quality. | Each print job |

| 10 | Stay updated on printing technologies. | Ensure competitive quality and efficiency. | Ongoing |

Best Practices For Color Printing On Thermal Labels Factories Global Reach Where Innovation Meets 2025

E

Ethan Hernandez

I highly recommend this product! The after-sales support exceeded my expectations.

18

June

2025

W

Wyatt Anderson

Impressive quality! The dedication shown by the customer support team was commendable.

06

June

2025

N

Nathaniel Rivera

Outstanding quality! Their expert support team made the experience delightful.

27

May

2025

R

Riley Gonzalez

Fantastic product! The quality is outstanding, and the after-sales team is very professional.

29

June

2025

I

Isabella Johnson

Thrilled with my order! The quality is excellent, and the staff’s professionalism is outstanding.

29

June

2025

L

Liam Thomas

Really top-quality product! The after-sales service was quick and very professional.

29

May

2025

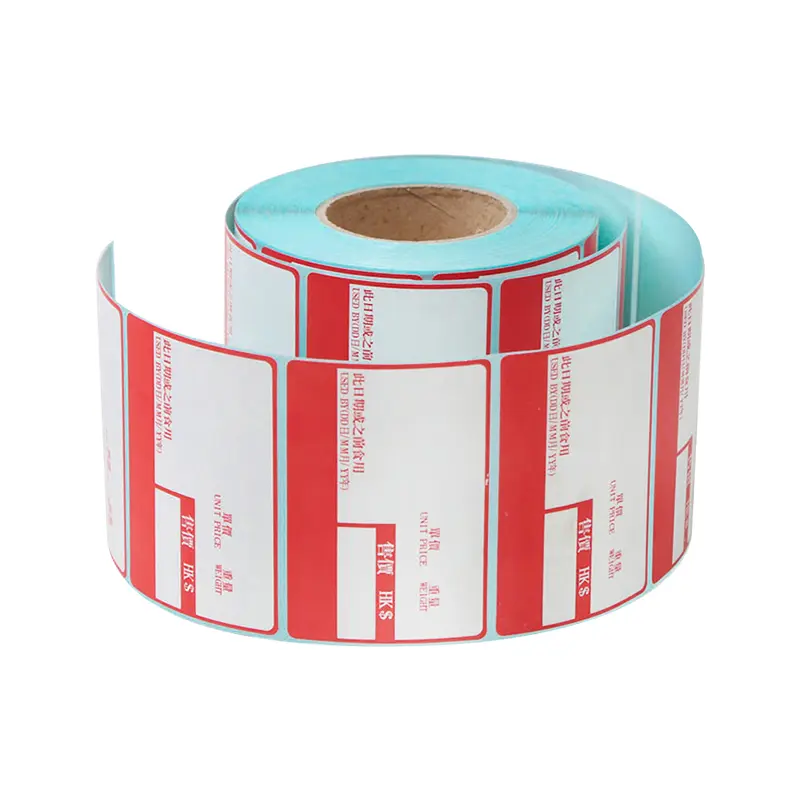

Thermal labels

Thermal labels