Thermal Transfer vs Direct Thermal Labels: Key Differences & Manufacturer Insights

When selecting labels for your business, it's important to comprehend the distinctions between thermal transfer and direct thermal labels. Thermal transfer labels are known for their longevity and durability, making them ideal for tough environments. Conversely, direct thermal labels are a more cost-effective choice suited for temporary applications.Expert Tips For Difference Between Thermal Transfer And Direct Thermal Labels For the Current Year Your End-to-End Solution

In today's fast-paced business environment, understanding the differences between thermal transfer and direct thermal labels is essential for optimizing your printing needs. At Sailing, an international leader in printing, packaging, and logistics consumables since 2011, we recognize that choosing the right labeling solution can significantly impact your product's presentation and operational efficiency.

Thermal transfer labels utilize a ribbon that melts the ink onto the label, producing high-quality, durable prints that resist fading and scratching. This makes them ideal for applications requiring long-lasting labels, such as shipping and inventory management. On the other hand, direct thermal labels are printed using heat-sensitive paper and are excellent for short-term uses, like shipping labels or receipts. They are more cost-effective for high-volume printing but may not stand up to environmental factors as well as thermal transfer labels.

As you consider your labeling options, think about the specific needs of your business, your budget, and how your labels will be used over time. Whether you require labels that resist wear and tear or those that can be produced quickly and affordably, Sailing's diverse range of products, produced in our state-of-the-art facilities in China and Malaysia, can accommodate your requirements. Let us guide you in making the best choice for your labeling needs, ensuring that your products stand out while maintaining efficiency in your logistics operations.

Expert Tips For Difference Between Thermal Transfer And Direct Thermal Labels For the Current Year Your End-to-End Solution

| Feature | Thermal Transfer Labels | Direct Thermal Labels |

|---|---|---|

| Durability | Highly durable; resistant to scratching and fading | Less durable; can fade with exposure to heat and light |

| Print Quality | Higher print quality; suitable for detailed graphics | Good print quality; best for simple barcodes and text |

| Cost | Generally more expensive due to ribbon costs | More affordable; no ribbon required |

| Application | Ideal for shipping labels, product labels, and artwork | Commonly used for receipts, shipping packages, and short-term labels |

| Printer Type | Requires thermal transfer printer | Compatible with direct thermal printers |

| Environmental Sensitivity | Less sensitive to environmental factors | More sensitive to heat, moisture, and sunlight |

Key Methods For Difference Between Thermal Transfer And Direct Thermal Labels Exceeds Industry Benchmarks Dominates

C

Charlotte Hall

I am very pleased with my order! Their support team was very professional and knowledgeable.

21

June

2025

H

Henry Evans

Excellent craftsmanship! I had a smooth experience with their competent support team.

25

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

J

James Robinson

Amazing quality! The customer service representatives showed real expertise and care.

18

May

2025

B

Benjamin Wright

Really high-quality product! The professionalism from the service team was a pleasant surprise.

29

June

2025

C

Cameron Lee

Outstanding product quality! The team provided insightful and prompt responses.

20

May

2025

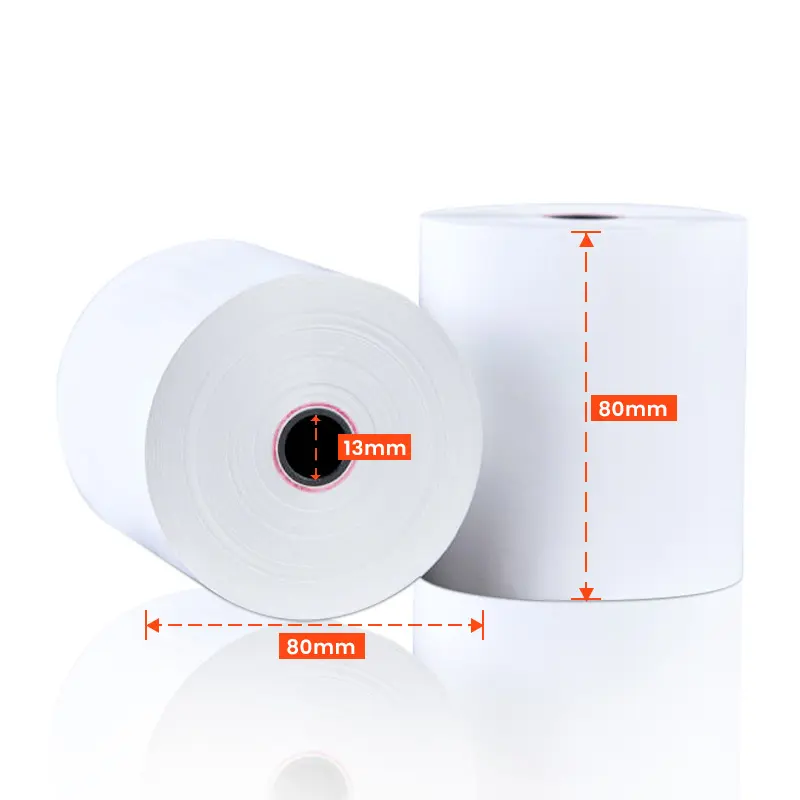

Thermal labels

Thermal labels