Direct Thermal Labels vs. Thermal Transfer Labels: Key Differences & Wholesale Outlook

When deciding between Direct Thermal Labels and Thermal Transfer Labels, it’s important to recognize their distinct features and applications. Direct thermal labels are ideal for short-term use, printing directly on the label without the need for ribbons. In contrast, thermal transfer labels are designed for longevity, using a ribbon to apply ink, making them suitable for more permanent labeling needs. At ShenZhen Sailing Paper Co., Ltd., we are committed to providing high-quality labels that cater to various applications, including shipping, inventory tracking, and product labeling. Our focus is on quality and durability, ensuring you receive products that align with your specifications. Partner with us for tailored labeling solutions that enhance your business operations.How To Pick The Right Direct Thermal Labels Vs Thermal Transfer Labels Manufacturer Manufacturers You Can Rely On Where Innovation Meets 2025

When it comes to sourcing direct thermal labels and thermal transfer labels, choosing the right manufacturer is crucial for ensuring product quality and operational efficiency. Since its inception in 2011, Sailing has evolved from a local paper converter into a renowned international group with manufacturing facilities strategically located in China and Malaysia. This experience not only guarantees our capacity to meet various printing and packaging demands but also underlines our commitment to innovation and sustainability in the label manufacturing industry.

In 2025 and beyond, global buyers need a reliable partner that understands the nuances between direct thermal and thermal transfer labels. Direct thermal labels are ideal for short-term applications as they produce images directly on the label surface, making them cost-effective for businesses focused on speed and efficiency. Conversely, thermal transfer labels offer greater durability and are suitable for long-term uses where resistance to environmental factors is vital. Choosing a manufacturer like Sailing, which emphasizes state-of-the-art technology and responsive customer service, ensures access to high-quality labels tailored to specific market needs.

Moreover, with a competitive landscape rapidly evolving, it’s essential to collaborate with a manufacturer that embraces innovation while maintaining rigorous quality controls. Sailing’s global footprint and dedication to cutting-edge production processes make us a trustworthy partner for your labeling needs. By prioritizing quality, efficiency, and sustainability, we empower businesses to thrive in a fast-paced market while effectively managing their printing and packaging requirements.

How To Pick The Right Direct Thermal Labels Vs Thermal Transfer Labels Manufacturer Manufacturers You Can Rely On Where Innovation Meets 2025

| Manufacturer Type | Label Technology | Innovative Features | Sustainability Practices | Market Reach |

|---|---|---|---|---|

| Direct Thermal | Direct Thermal | Fast Printing Speed | Recyclable Materials | Global |

| Thermal Transfer | Thermal Transfer | High Durability | Eco-Friendly Inks | Regional |

| Hybrid Solutions | Both Technologies | Versatile Applications | Energy Efficient Processes | International |

| Specialty Labels | Custom Solutions | Unique Adhesive Technologies | Sustainable Sourcing | Niche Markets |

How To Compare Direct Thermal Labels Vs Thermal Transfer Labels Manufacturer Is The Best Now Trending

J

Jacob Gonzalez

This product delivers on quality! The after-sales support was knowledgeable and efficient.

25

May

2025

N

Natalie Turner

Great purchase! The quality is excellent and the service staff is incredibly professional.

17

May

2025

L

Lucy Thompson

I am extremely satisfied! The service staff displayed remarkable professionalism and skill.

02

July

2025

L

Liam Diaz

The product quality is exceptional! The after-sales support was quick and very helpful.

06

May

2025

H

Henry Williams

Top-notch quality! I appreciate how professional and prompt their service team has been.

03

June

2025

J

Jackson Wright

I’m very impressed! The craftsmanship is excellent and customer service was very attentive.

13

May

2025

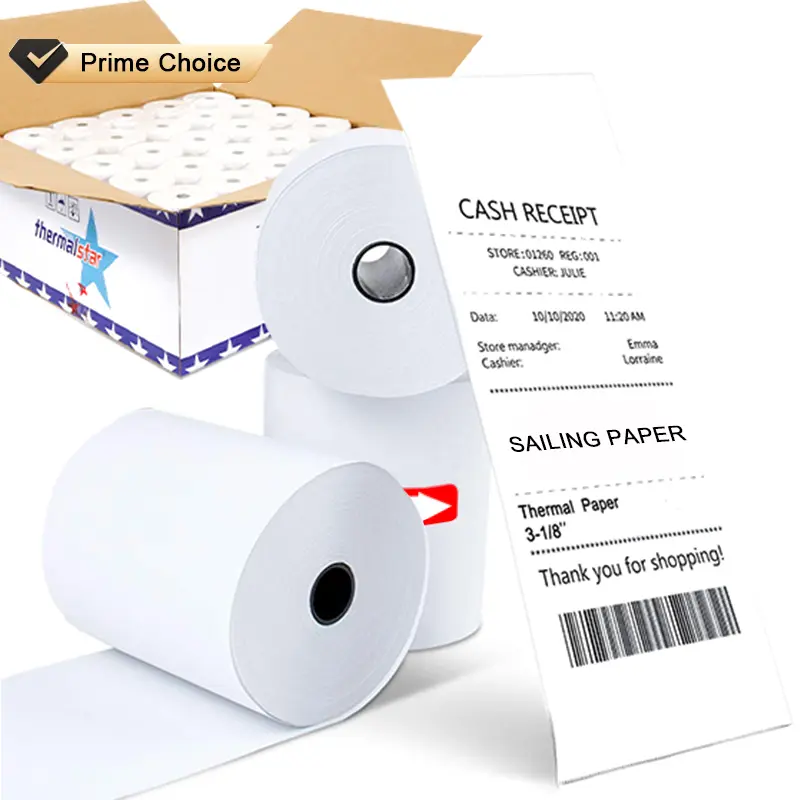

Thermal labels

Thermal labels