Top High Speed Slitting Machine Manufacturers & Exporters for Quality Solutions

Reliable high-speed slitting machines are essential for maximizing efficiency in production lines. At ShenZhen Sailing Paper Co., Ltd., we specialize in supplying top-quality equipment sourced from trusted Chinese exporters and suppliers. Our machines are engineered for precision, ensuring durability and exceptional performance across various materials, ideal for applications in paper, film, and foil conversion. With our extensive industry experience, we guarantee that our high-speed slitting machines will enhance your operations, boost output, and streamline processes. Emphasizing quality, reliability, and competitive pricing, we are committed to assisting you in achieving greater productivity. Contact us to elevate your manufacturing capabilities!

Must-Know Tips For High Speed Slitting Machine Factories Factory Where Innovation Meets 2025

In the rapidly evolving landscape of manufacturing, high-speed slitting machine factories are at the forefront of innovation and efficiency. As we approach 2025, it’s vital for global buyers to understand the key features and advantages that distinguish top-tier factories in this sector. Sailing, a prominent player in the industry since 2011, has transformed from a local paper converter to an international group with strong production bases in both China and Malaysia. This growth has positioned us uniquely to cater to diverse markets and meet the dynamic needs of printing, packaging, and logistics consumables.

For procurement specialists, engaging with a factory that prioritizes innovation means gaining access to cutting-edge technology and streamlined processes. Sailing’s commitment to quality not only enhances the performance of our high-speed slitting machines but also minimizes operational downtimes for our clients. We ensure that our machines are equipped with advanced features such as automated adjustments and real-time monitoring systems, allowing factories to maximize production efficiency and reduce waste.

As we look ahead, networking and building strong partnerships with manufacturers like Sailing will be essential for global buyers seeking reliability and innovation in their supply chain. By choosing a factory that embodies these principles, businesses can ensure that they remain competitive in the ever-changing marketplace, ready to meet the demands of an increasingly complex world.

Must-Know Tips For High Speed Slitting Machine Factories Factory Where Innovation Meets 2025

| Tip | Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| Optimize Blade Profiles | Use advanced blade designs to enhance cutting efficiency. | Reduction in material waste and increased cutting speed. | 6 months |

| Implement IoT Sensors | Integrate IoT technology for real-time performance monitoring. | Improved machine health and predictive maintenance. | 9 months |

| Train Workers Regularly | Conduct ongoing training for operators on best practices. | Increased operational efficiency and safety. | Ongoing |

| Utilize Automated Controls | Use automation for precision in speed and tension control. | Better product quality with fewer defects. | 12 months |

| Sustainability Practices | Adopt eco-friendly materials and recycling programs. | Reduction in carbon footprint and improved brand image. | 8 months |

Not to Be Missed High Speed Slitting Machine Factories Industry Giant Trusted by Pros

M

Matthew Rodriguez

Impressive quality and design! I appreciate the professional manner in which my inquiries were handled.

04

July

2025

M

Mason Carter

Exceptional product quality! The after-sales personnel were exemplary in their professionalism.

13

May

2025

S

Sofia Mitchell

Absolutely wonderful quality! Their team demonstrated unparalleled professionalism throughout.

01

July

2025

E

Ethan Scott

Quality is exceptional! Support team handled my concerns with utmost professionalism.

22

June

2025

M

Michael Carter

Remarkable experience! The quality is superior, and their service team is incredibly professional.

24

June

2025

L

Lily Walker

Very happy with my purchase! The quality is excellent and customer service was great.

25

May

2025

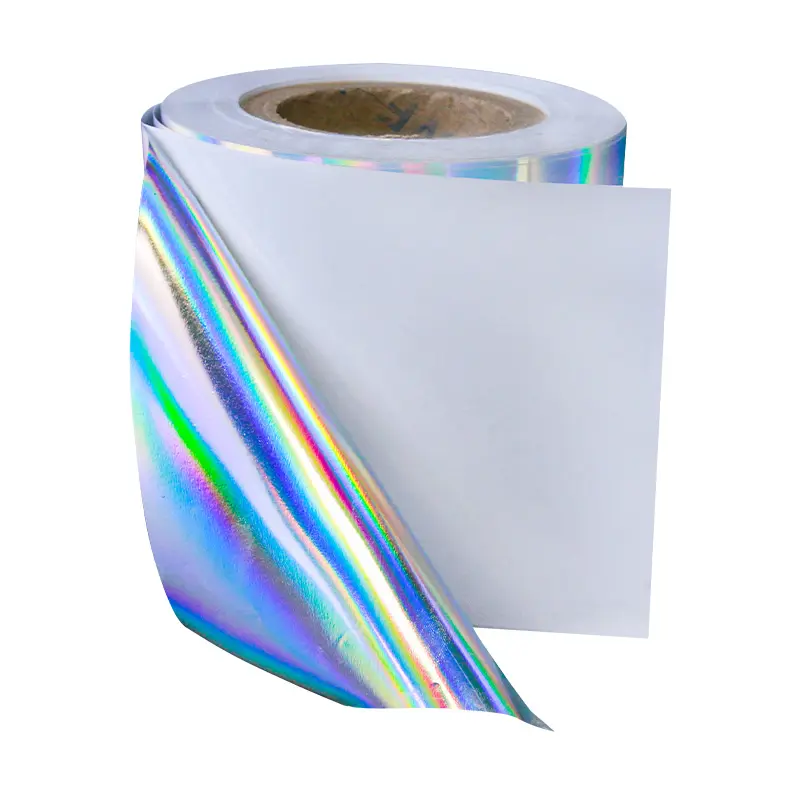

Thermal labels

Thermal labels