Guide to Manufacturing Thermal Paper Rolls: Renowned China Factories & Companies

High-quality thermal paper rolls are essential for efficient business operations, and at ShenZhen Sailing Paper Co., Ltd., we specialize in manufacturing customized solutions that cater to your specific needs. As a reliable wholesale supplier, we provide competitive pricing to ensure our products fit your budget. Our rigorous manufacturing process guarantees exceptional print quality and durability for a range of applications, including receipts and labels. Whether you operate a retail store, a restaurant, or any business requiring thermal paper, we are prepared to fulfill your requirements. Contact us today for a personalized quote and experience the benefits of our superior products.Methods To choose How To Manufacture Thermal Paper Roll Custom Solutions, Ahead of the Curve

In today's fast-paced global market, choosing the right manufacturer for thermal paper roll custom solutions is crucial for businesses looking to stay ahead of the curve. Since its inception in 2011, Sailing has transformed from a local paper converter into a prominent international group company with production facilities in both China and Malaysia. This strategic positioning allows us to cater to a diverse range of client needs while maintaining high-quality standards and competitive pricing.

When selecting a manufacturer for thermal paper rolls, consider several key factors. First, assess the manufacturer’s production capacity and technology. Sailing employs state-of-the-art machinery and processes to ensure consistent quality and efficiency in production. Additionally, evaluate their expertise in customization; our team specializes in creating tailored solutions that meet specific client requirements, from size and thickness to printing capabilities. Furthermore, strong supply chain management is essential for timely delivery and reducing lead times, allowing you to meet fluctuating market demands seamlessly.

Lastly, prioritize sustainability and compliance when choosing your supplier. At Sailing, we are committed to environmentally responsible practices, ensuring our products are eco-friendly without compromising on quality. By partnering with us, you can rest assured that you are aligned with a manufacturer that not only meets your business needs but also shares your commitment to sustainability. Make informed decisions and stay ahead in the competitive landscape of printing, packaging, and logistics consumables.

Methods To Choose How To Manufacture Thermal Paper Roll Custom Solutions, Ahead of the Curve

| Dimension | Description | Considerations | Customization Options |

|---|---|---|---|

| Width | The width of the thermal paper roll. | Ensure compatibility with printers. | Custom widths available from 40mm to 210mm. |

| Length | The length of each roll. | Longer lengths can reduce the need for frequent changes. | Options range from 10m to 300m. |

| Core Size | Inner diameter of the paper core. | Check compatibility with printer spindles. | Typical sizes include 12mm, 25mm, and 40mm. |

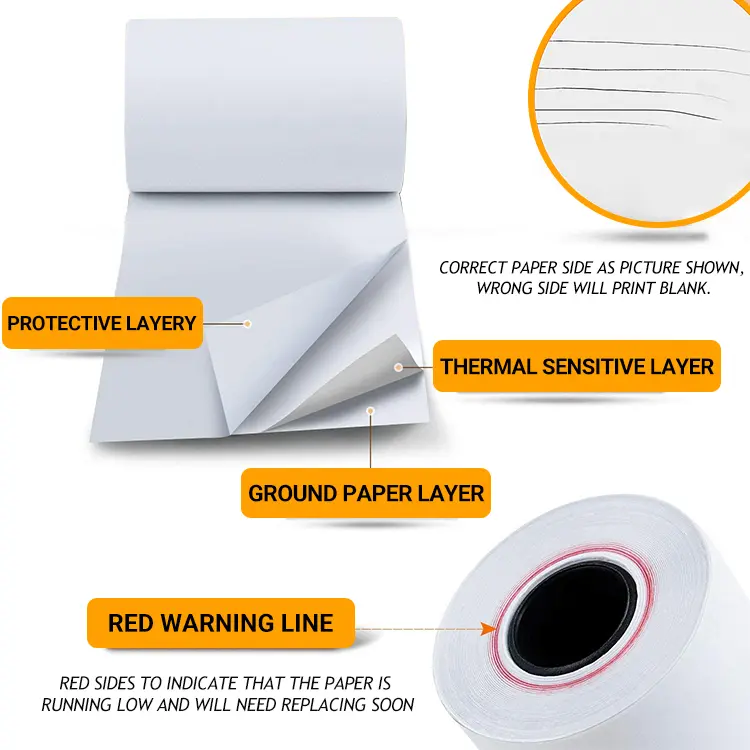

| Paper Quality | Quality of thermal paper affecting print clarity. | Higher quality yields better print quality and longevity. | Standard, premium, and extra smooth options. |

| Coating Type | Type of coating to enhance print and durability. | Determine if a thermal or chemical coating is preferred. | Options include BPA-free and eco-friendly coatings. |

Discovering How To Manufacture Thermal Paper Roll Factory Winning in 2025

C

Charlotte Hall

I am very pleased with my order! Their support team was very professional and knowledgeable.

21

June

2025

S

Sofia Mitchell

Absolutely wonderful quality! Their team demonstrated unparalleled professionalism throughout.

01

July

2025

L

Liam Diaz

The product quality is exceptional! The after-sales support was quick and very helpful.

06

May

2025

C

Camila Long

I adore this product! The support staff was incredibly knowledgeable and responsive.

22

June

2025

M

Matthew Scott

This product is of excellent quality! Service was attentive, professional, and smooth.

06

May

2025

B

Benjamin Wright

Really high-quality product! The professionalism from the service team was a pleasant surprise.

29

June

2025

Thermal labels

Thermal labels