Label Maker Thermal vs Non-Thermal: A Guide to Wholesale Suppliers & Companies

Choosing the right label maker requires understanding the differences between thermal and non-thermal options. Thermal label makers excel in efficiency and cost-effectiveness, making them ideal for high-volume tasks. In contrast, non-thermal options offer greater versatility in label materials and styles. ShenZhen Sailing Paper Co., Ltd. is a noteworthy company in this industry, delivering high-quality products tailored to specific needs. With expertise in label-making, they ensure optimal solutions for both temporary and durable labels. Evaluating both types of label makers based on your specific requirements can significantly enhance productivity in your operations.

Decoding Label Maker Thermal Vs Non Thermal Your End-to-End Solution Guarantees Peak Performance

In today's fast-paced business environment, choosing the right label maker can significantly impact your operations. At Sailing, we understand this crucial decision and aim to provide a comprehensive solution for global procurement needs. Since our establishment in 2011, we have evolved from a local paper converter into a recognized international entity, with production facilities in both China and Malaysia. Our expertise lies in the manufacturing and export of high-quality printing, packaging, and logistic consumables that cater to diverse industries.

When considering label makers, one key aspect to evaluate is the technology behind them: thermal vs. non-thermal. Thermal label makers utilize heat to transfer ink onto labels, ensuring sharp and durable prints, perfect for extensive use. In contrast, non-thermal solutions rely on ink cartridges, which may incur additional costs and require more maintenance. By choosing a thermal label maker, companies can guarantee peak performance, reducing downtime and enhancing productivity. At Sailing, we are dedicated to providing reliable labeling solutions that align with your operational goals, helping you streamline processes and reduce costs effectively.

Our global reach and commitment to quality ensure that you receive not just products, but end-to-end solutions tailored to your specific requirements. With our extensive range of printing and packaging supplies, you can trust Sailing to empower your business with the tools necessary for success in the competitive market landscape. Partner with us to experience operational excellence and maximize the potential of your label-making endeavors.

Decoding Label Maker Thermal Vs Non Thermal Your End-to-End Solution Guarantees Peak Performance

| Feature | Thermal Label Makers | Non-Thermal Label Makers |

|---|---|---|

| Print Quality | High resolution, sharp text and images | Varies with cartridge quality; usually good but less consistent |

| Operating Cost | Low cost per label; no ink or toner required | Higher cost per label; requires ink or toner |

| Speed | Fast, ideal for high-volume printing | Slower; depends on the model and complexity |

| Durability of Labels | Resistant to water, heat, and fading | May fade or smudge over time |

| Initial Investment | Generally lower | Typically higher due to equipment and material needs |

| Maintenance | Low; few moving parts | May require regular maintenance and replacements |

Top 3 Label Maker Thermal Vs Non Thermal Your Trusted OEM Partner Pioneers in the Field

S

Sophie Hall

Perfect purchase! The product quality is sublime, and the service team exhibits great professionalism.

10

June

2025

V

Victoria Wright

The quality of this product is fantastic! I appreciated the professionalism of the team.

01

July

2025

N

Nathaniel Rivera

Outstanding quality! Their expert support team made the experience delightful.

27

May

2025

S

Sophia Reed

Fantastic purchase! The product is of high quality, and their service team is very professional.

07

June

2025

G

Grace Hall

Impressive quality! The professionalism of the service team made a positive impact on my experience.

24

May

2025

C

Chloe Young

Wonderful quality! The knowledge of their support staff really helped me with my purchase.

27

June

2025

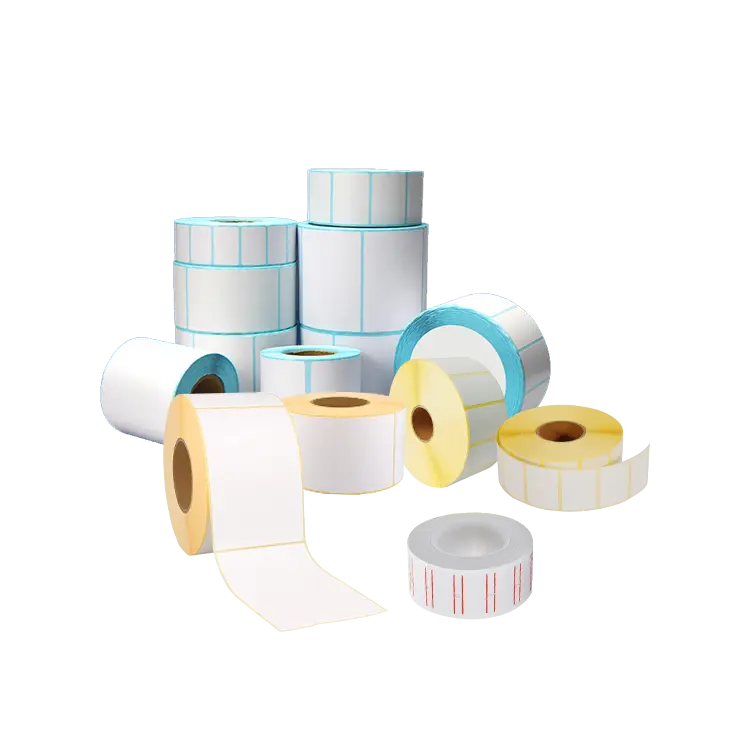

Thermal labels

Thermal labels