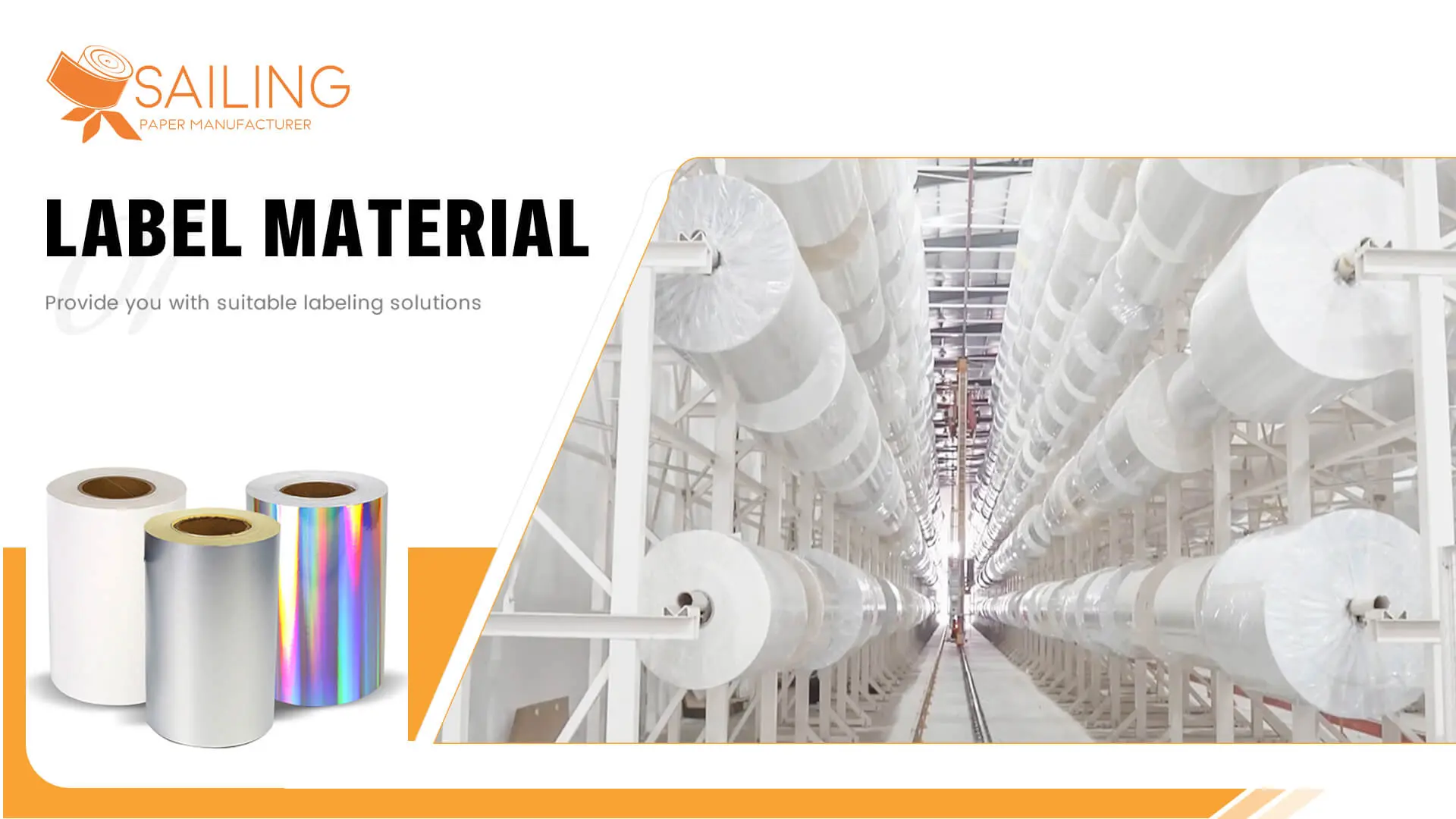

Product Overview

Paper-based Face Stocks

Thermal Paper

• Cost-effective for large-scale usage

• Good barcode printability and contrast

• Easy converting and rapid imaging

Art Paper(Coated paper)

Balanced performance between cost and quality

• Good ink absorption and sharp print quality

• Compatible with ribbon and multiple print methods

Woodfree Paper

• Writable surface, ideal for office use

• Low-cost, widely available

• Accepts multiple printing techniques

Self-Adhesive Label Facestock – Film

Synthetic Paper

• Excellent ink absorption and print quality

• Tear-proof and water-resistant

• Performs well on dark bottles and die-cutting processes

BOPP

• Excellent moisture and chemical resistance

• Good die-cutting and registration performance

• Strong dimensional stability and clarity

PE (Polyethylene)

• Flexible and conformable for curved surfaces

• Good print adaptability and die-cutting performance

• Excellent for lightweight packaging

Pearl Film

• Premium pearlescent appearance without metallic film

• Strong stiffness and opacity

• Enhanced printability with surface treatment

Product Parameters

| Parameter | Specification |

| Material Type | Thermal / Coated Paper / PET / PP etc. |

| Thickness | 50 – 120 gsm |

| Adhesive Options | Permanent / Removable / Re-sealable |

| Surface Finish | Matte / Glossy / Transparent |

| Roll Size | Customizable |

| Core Diameter | 25mm / 40mm / 76mm |

Adhesives Solutions

| Classification | Min. Application Temp. | Service Temp. Range | Applicability | Application Field |

| Hot melt | 10℃ | -15℃ ~ 90℃ | Universal permanent rubber-based adhesive, suitable for m ost surface materials, with good initial and final adhesion. |

Mainly used in express logistics, supermarkets, food, daily chemicals, pharmaceuticals, etc. |

| Hot melt (for low temp.) | -10℃ | -25℃ ~ 65℃ | Specially designed for low temperature and cold envir onments, maintaining good adhesion and viscosity. |

Mainly used in cold chain, frozen food, express logistics. |

| Hot melt (anti-freezing) | -20℃ | -35℃ ~ 25℃ | Designed for frozen and refrigerated conditions, maintaining adhesion in extremely low temperatures. |

Mainly used in fresh food, refrigeration, cold chain. |

| Acrylic | 10℃ | -20℃ ~ 100℃ | Universal high-viscosity permanent acrylic emulsion adhesive with good adhesion on various substrates. | Mainly used in supermarkets, offices, home appliances, packaging, food, logistics, pharmaceuticals, etc. |

| Acrylic (for films) | 10℃ | -20℃ ~ 100℃ | Universal film acrylic adhesive, good initial and final adhesion, specially suitable for film labels. | Mainly used in beverages, daily chemicals, personal care, durable film labeling. |

| Removable adhesive | 10℃ | -20℃ ~ 80℃ | Acrylic-based removable adhesive, wide application range, easy peel-off without residue. | Mainly used in transfer labels, furniture, office, personal care. |

Release Liner Solution: Invisible Support

Key Functions of Release Liners

Common Types of Release Liners

Customization Options

Every business has unique labeling needs, and Sailing Paper understands that one solution does not fit all. By offering flexible customization across material types, adhesives, sizes, finishes, packaging, and release liners, the company ensures clients receive products tailored to their exact requirements. This flexibility helps distributors, brand owners, and manufacturers improve efficiency, enhance brand identity, and adapt to diverse application environments.

Sailingpaper Factory Strength

The strength of a self adhesive labeling material manufacturer lies in its factory capability. Sailing Paper operates a dedicated label material factory with advanced coating, slitting, and converting lines, supported by strict quality control and professional management. This strong manufacturing base enables us to deliver stable supply, consistent quality, and flexible customization for clients across different industries worldwide.

-

12,000 ㎡Factory Area

12,000 ㎡Factory Area -

3,120+Export containers per year

3,120+Export containers per year -

2 DayREADY STOCK、2 Days delivery

2 DayREADY STOCK、2 Days delivery -

1,200,000 m²Monthly output

1,200,000 m²Monthly output

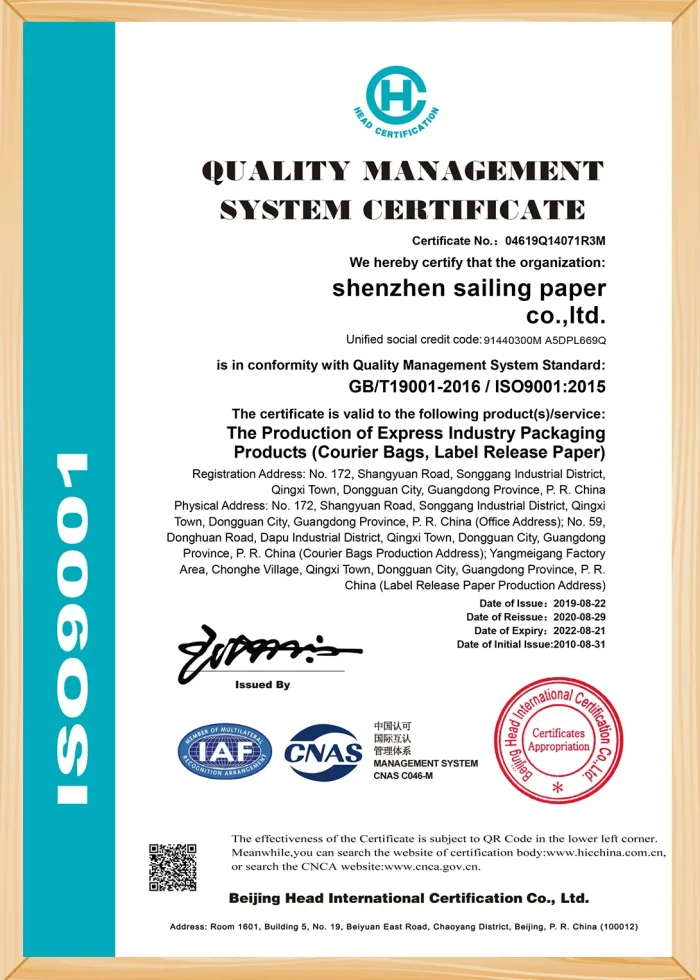

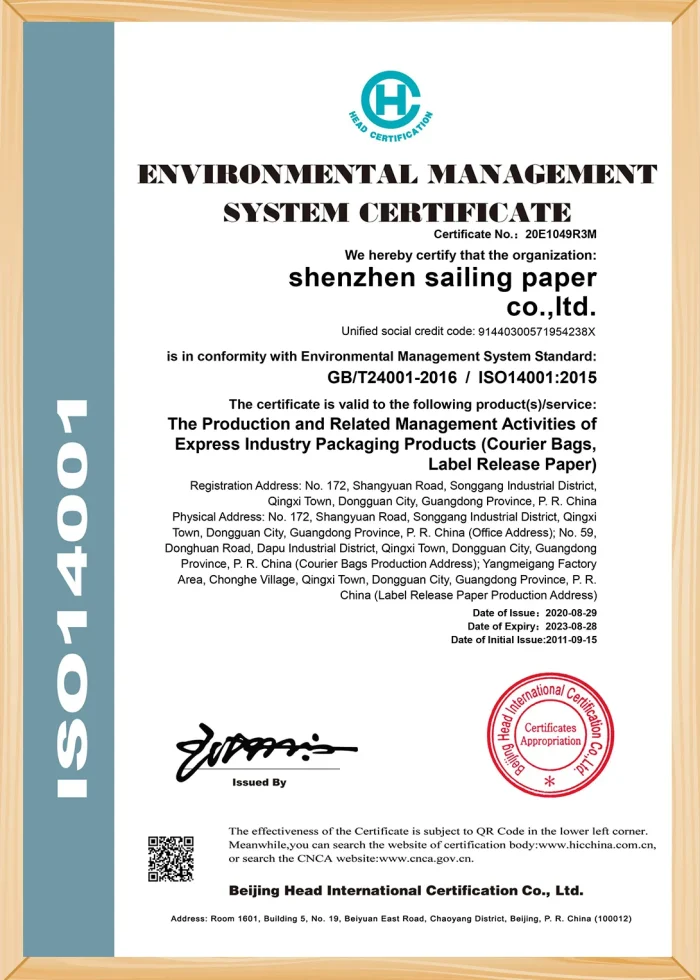

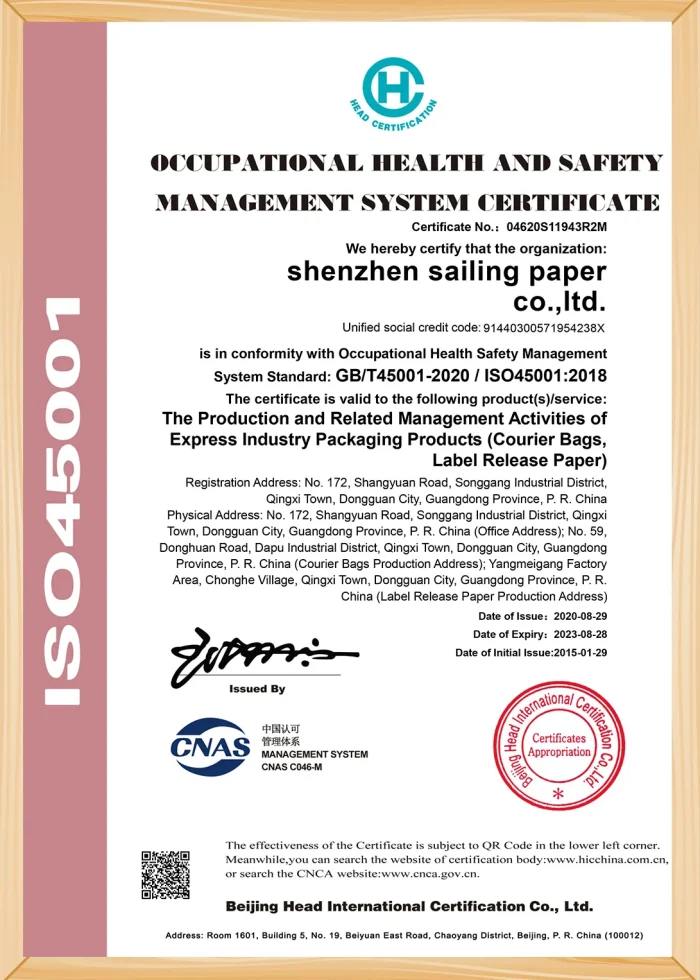

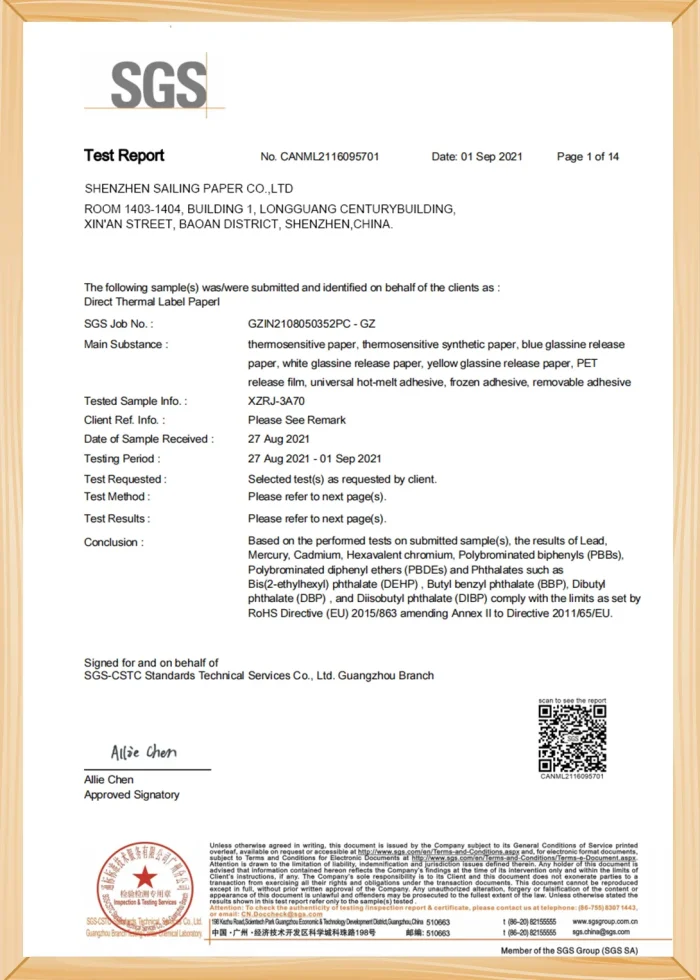

Certifications & Quality Assurance

For best label materials, quality and compliance are critical to performance and market acceptance. Sailing Paper’s certifications demonstrate our strict adherence to international standards in safety, durability, and environmental responsibility. Each certificate proves that our label materials undergo rigorous testing and are recognized by global authorities, giving clients the confidence that every roll and sheet they use is both reliable and compliant.

Sailingpaper

Direct Factory Price

Choosing a direct factory supplier means more than just getting a product—it ensures reliability, cost efficiency, and stable long-term cooperation. As a professional label material manufacturer, Sailing Paper delivers true factory-direct value by controlling every step from raw materials to finished rolls.

Quality Inspection

Sailing Paper regards quality as the foundation of trust. Every roll of material labels undergoes strict quality control to ensure durability, printability, and adhesive performance. From raw material inspection to final shipment testing, each step is carefully monitored, guaranteeing clients consistent and reliable products.

Export & Logistics

For global clients of performance label materials, safe and efficient logistics are just as important as product quality. Sailing Paper ensures every shipment of label materials is carefully packed, palletized, and loaded to meet international transport standards. With strong export experience and partnerships with reliable carriers, we guarantee that every order reaches clients securely, on time, and in cost-effective ways.

Shipping via DHL, UPS, sea freight, FBA, ensuring fast and timely delivery.

Delivery Lead Time

For materials label orders, timely delivery is essential to keep clients’ supply chains running smoothly. Sailing Paper combines ready stock, efficient production scheduling, and flexible logistics solutions to ensure every order is fulfilled without delay. With clear schedules and transparent pre-shipment updates, clients can plan confidently, knowing their label materials will arrive safely and on time.

-

Standard stocked layouts: shipped within 48 hours

-

Custom production: delivered in 7–15 working days

-

Production updates and carton photos available for approval

After-Sales Service

Contact us now to get a quote

Request Free Samples, Or Start Your Custom Design! Fast Response, Global Service, Direct Factory Support.

Thermal labels

Thermal labels