High-Quality Labels for Hazardous Lithium Ion Battery Materials | Request Quotes Now

Shipping lithium-ion batteries requires a strong emphasis on safety, which is why I trust ShenZhen Sailing Paper Co., Ltd. for high-quality hazardous materials shipping labels. These labels are crafted to meet the latest compliance standards, ensuring that every shipment adheres to regulations and keeps the cargo secure. Partnering with a reputable exporter who understands the challenges of marine and air transport adds significant value to my process. The commitment to quality is evident in every label, making my shipments easily recognizable during transit. With a diverse range of labels available, both small businesses and larger enterprises can benefit from their designs. By utilizing these labels, I enhance my shipping procedures and foster trust with clients by prioritizing safety and compliance during shipments of lithium-ion batteries.

How Chinese Manufacturers Lithium Ion Battery Hazardous Materials Shipping Label Manufacturer Manufacturer Factory

In recent years, the demand for lithium-ion batteries has surged globally, leading to the increasing complexity of regulations surrounding the shipping of hazardous materials. To address these challenges, it is crucial for manufacturers to work with reliable shipping label providers. Since our establishment in 2011, Sailing has evolved from a local paper converter into a robust international group, with production facilities in China and Malaysia. Our commitment to quality and compliance in producing printing, packaging, and logistic consumables has made us a preferred partner for businesses navigating the regulations of hazardous materials.

At Sailing, we understand the specific needs of manufacturers in the lithium-ion battery industry. Our expertise allows us to create precise shipping labels that comply with international standards, ensuring safe and efficient transport of hazardous materials. By leveraging our advanced technology and knowledge of regulatory requirements, we offer solutions that not only enhance operational efficiency but also help businesses mitigate risks associated with shipping hazardous substances. As global procurement trends continue to shift towards responsible sourcing and sustainability, partnering with a manufacturer that prioritizes quality and compliance is essential.

Our global footprint and dedication to customer satisfaction position Sailing as a valuable ally for manufacturers and exporters around the world. With a comprehensive range of products tailored to meet the needs of various industries, we are committed to supporting your business goals while ensuring compliance with all regulatory demands. Together, we can navigate the complexities of hazardous materials shipping and propel your business towards sustainable success.

How Chinese Manufacturers Lithium Ion Battery Hazardous Materials Shipping Label Manufacturer Manufacturer Factory

| Manufacturer Type | Shipping Label Type | Material Safety Data Sheet (MSDS) | Compliance Standards | Region |

|---|---|---|---|---|

| Lithium Ion Battery Manufacturer | UN3480 - Lithium Ion Batteries | Available | IATA, IMDG | Asia |

| Lithium-ion Battery Pack Manufacturer | UN3481 - Lithium Ion Batteries Packed with Equipment | Available | DOT, ICAO | Asia |

| Battery Recycling Manufacturer | Hazardous Waste | Not Required | EPA | North America |

| Portable Battery Manufacturer | UN3090 - Lithium Batteries | Available | IATA, DOT | Europe |

How To Select Lithium Ion Battery Hazardous Materials Shipping Label Manufacturer Guarantees Peak Performance Industry Giant

S

Sophie Hall

Perfect purchase! The product quality is sublime, and the service team exhibits great professionalism.

10

June

2025

L

Lily Torres

Superb quality! Customer support was prompt and professional, making the buying process easy.

31

May

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

G

Grace Hall

Impressive quality! The professionalism of the service team made a positive impact on my experience.

24

May

2025

Z

Zoe Gonzalez

Absolutely outstanding! The quality of the product and the service were both exemplary.

16

May

2025

N

Natalie Torres

Incredible quality! Their support staff was prompt and skilled in addressing my questions.

01

June

2025

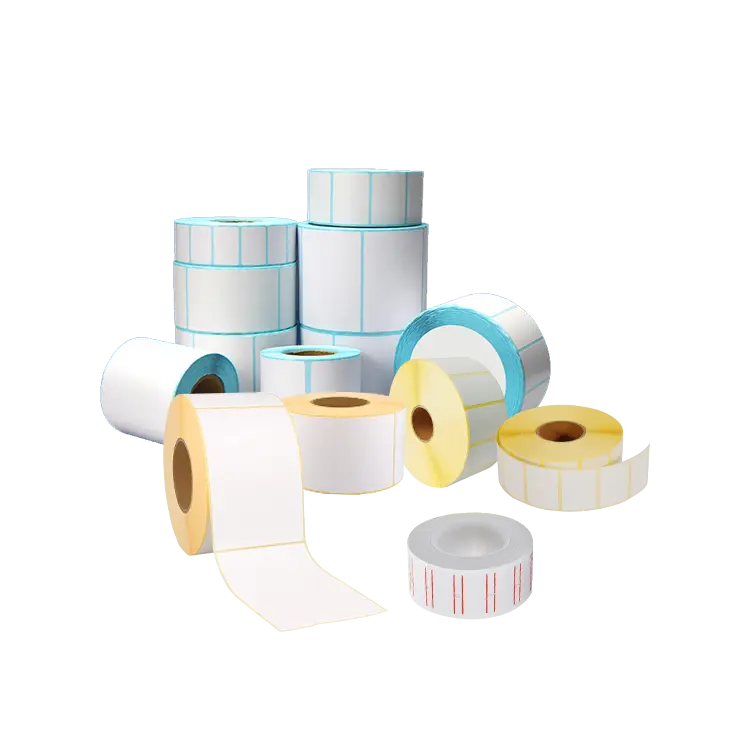

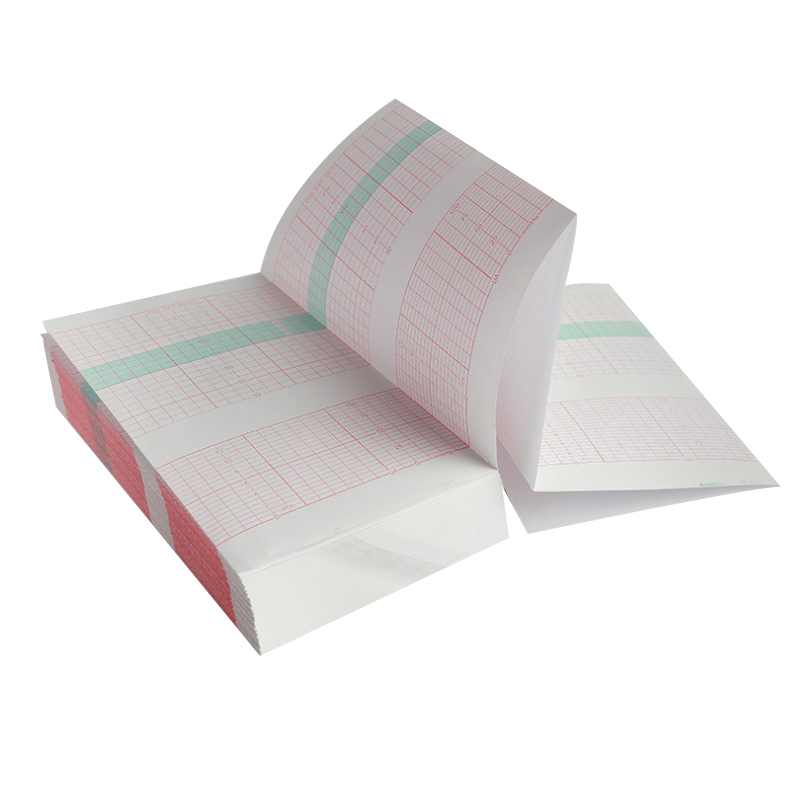

Thermal labels

Thermal labels