Printed Barcode Labels: A Comprehensive Guide

In today's fast-paced and tech-driven world, businesses rely on accurate, efficient methods for tracking products, managing inventory, and ensuring smooth operations. One of the most effective tools for achieving these goals is the use of printed barcode labels. These small but powerful labels hold the key to a wide range of applications, from product labeling to inventory management. In this article, we will explore the different aspects of barcode labels, including their types, printing processes, customization options, and the many industries that benefit from barcode labelling.

What Are Printed Barcode Labels?

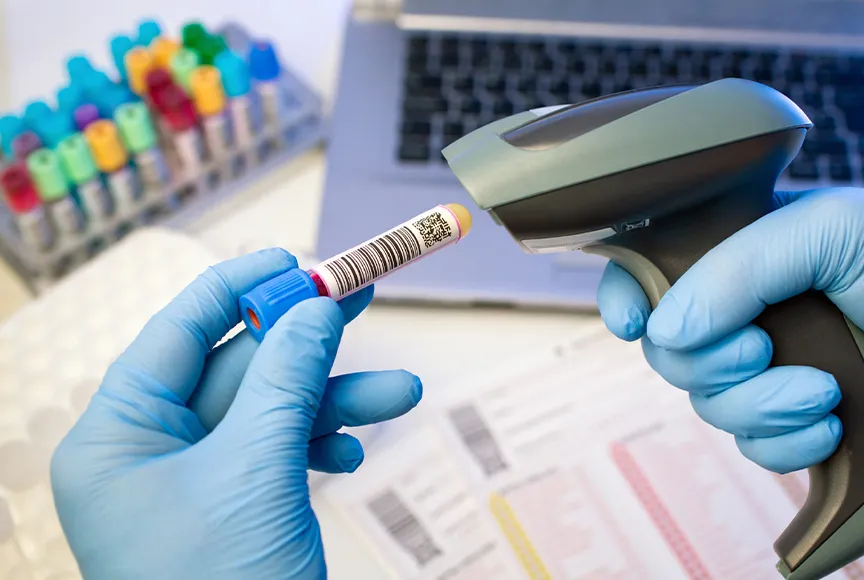

Printed barcode labels are adhesive or non-adhesive tags that contain a barcode—a series of lines and numbers that can be scanned by a barcode reader to retrieve product or inventory information. These labels can be used for a variety of purposes, including tracking products in retail stores, labeling shipments in logistics, or managing stock in warehouses. The efficiency of barcode labeling has made it an essential tool in modern business operations.

Types of Barcode Labels

There are several types of barcode labels designed for different applications. Below are the most common:

1.Product Label Barcode: These are the labels typically found on retail products. They contain barcodes that are scanned during checkout to help businesses track sales and manage inventory.

2.Inventory Labels Barcode: Used in warehouses and distribution centers, these labels help track the movement of products and ensure that stock levels are always updated.

3.Sequential Barcode Labels: These are barcode labels printed with serial numbers in sequence. They are particularly useful for tracking unique items such as electronics or tools that require individual identification.

4.Barcode Security Labels: These labels provide an additional layer of protection by incorporating features such as tamper-evident designs, making them difficult to duplicate or remove without leaving a trace. These are commonly used in the pharmaceutical industry or for high-value items.

How to Print Barcode Labels

Printing barcode labels is a straightforward process, but it requires the right equipment and materials. Below is a step-by-step guide on how to print barcode labels for various applications.

Step 1: Select the Right Barcode Printer

The first step in the barcode label printing process is selecting the right barcode printer. Barcode printers come in two primary varieties:

● Thermal Printers: These printers use heat to transfer ink onto the label. They are known for producing durable prints, especially when used for waterproof barcode labels or industrial barcode labels that need to withstand harsh conditions.

● Inkjet Printers: These are often used for smaller batches or when printing high-quality color labels, such as custom printed barcode labels.

Step 2: Choose the Right Label Material

Choosing the right material for your labels is crucial to ensure the labels last and remain readable. Some common materials include:

● Paper Labels: Ideal for standard use in retail environments. They are less durable but cost-effective.

● Synthetic Labels: Materials like polyester or vinyl are used for waterproof barcode labels and other applications requiring durability.

● Industrial Barcode Labels: These labels are made from tough materials that can withstand extreme conditions such as high temperatures, moisture, or abrasion.

Step 3: Use Barcode Label Templates

A barcode label template can simplify the design process. These templates are pre-configured with spaces for barcode placement and allow for easy adjustments to fit your brand’s design needs. Software programs like Adobe Illustrator, Microsoft Word, or specialized label software can help you customize the design.

Step 4: Printing and Applying the Labels

Once you’ve selected the printer, label material, and design, it’s time to print the labels. Ensure that the printer is set to the correct label size (e.g., 4 x 6 barcode labels) and that the labels are aligned correctly on the sheet or roll. After printing, the labels can be applied to your products, equipment, or inventory.

Custom Printed Barcode Labels

Custom printed barcode labels offer businesses the flexibility to create labels that fit their specific needs. Whether you need special barcode sizes, logos, or unique design elements, custom labels are the way to go.

Why Choose Custom Barcode Label Printing?

1.Tailored Design: Custom labels allow businesses to create unique designs that match their branding and operational requirements.

2.Barcode Label Sizes: You can choose from a wide range of sizes, from small blank barcode labels for tiny products to larger labels like 4 x 6 barcode labels for shipping boxes or pallets.

3.Durability: Custom labels can be made with high-quality materials such as tamper-resistant films or waterproof coatings, ensuring they stand the test of time.

4.Enhanced Security: Adding features like barcode security labels can help protect valuable products from theft or tampering.

Working with a Barcode Label Manufacturer

If your business requires large quantities of custom labels or specialized designs, working with a barcode label manufacturer can be highly beneficial. These manufacturers have the expertise to create high-quality labels that meet specific requirements, including unique barcode formats, security features, or compliance with industry standards.

Barcode Printer Labels

Barcode printer labels are specifically designed to work with barcode printers, ensuring high-quality, scannable prints for various applications. These labels come in rolls or sheets compatible with thermal, inkjet, or laser printers and are ideal for retail, logistics, and healthcare industries. Using the right labels enhances printing accuracy and reduces errors, ensuring seamless operations.

Barcode Label Sheets

Barcode label sheets are pre-cut adhesive sheets designed for efficient multi-label printing. They are perfect for businesses needing smaller quantities or a variety of label sizes in one print job. These sheets are compatible with most standard printers, making them a cost-effective option for small-scale printing.

Industrial Barcode Labels

Industrial barcode labels are built to withstand extreme conditions, such as high temperatures, moisture, chemicals, or abrasion. They are commonly used in manufacturing, logistics, and construction industries to track equipment, machinery, or heavy-duty inventory. Made from durable materials like polyester or metalized film, these labels ensure longevity and reliability even in harsh environments.

The Importance of Barcode Labels in Various Industries

Barcode labels are crucial across various industries, as they enable efficient inventory management, improve accuracy, and reduce operational costs. Here’s a look at how different sectors benefit from barcode labelling:

Retail

In the retail industry, product label barcodes are used to streamline the checkout process, track sales, and manage inventory. Scanning a barcode at checkout provides instant information on pricing, product availability, and stock levels. Retailers also use barcode labels to organize stock, reorder products, and reduce the likelihood of human error.

Logistics and Shipping

For logistics companies, inventory labels barcode are essential for managing the movement of goods throughout the supply chain. Barcode labels are attached to packages or pallets, making it easy to track shipments, monitor their locations, and ensure timely deliveries.

Healthcare

Barcode labels play a critical role in healthcare, ensuring the accurate tracking of medical equipment, medication, and patient information. For example, barcode equipment labels are used to track medical devices, reducing the chances of misplacing equipment and ensuring proper maintenance.

Manufacturing

In manufacturing, sequential barcode labels are used for serialized items or parts, helping companies maintain detailed records of their inventory. This ensures that each product or part can be traced back to its source in the event of a defect or recall.

Conclusion

Printed barcode labels are an essential tool for businesses across industries, offering a range of benefits from enhanced efficiency to improved security. Whether you’re printing labels for retail products, inventory tracking, or industrial applications, understanding the different types of labels and the printing process is crucial to selecting the right solution for your needs.

With the ability to customize labels for size, durability, and security, businesses can ensure that their operations run smoothly, from barcode label printing to the final application on products or equipment. Working with a barcode label manufacturer can also help streamline the process, providing high-quality, custom-designed labels that meet your exact requirements.

From waterproof barcode labels for harsh environments to 4 x 6 barcode labels for shipping, the possibilities are endless when it comes to choosing the right barcode labelling solution.

Please get in touch with us if you're interested in this product!

Thermal labels

Thermal labels