Thermal labels: efficient solutions and a wide range of applications in detail

What is thermal label?

What are the benefits of thermal printing?

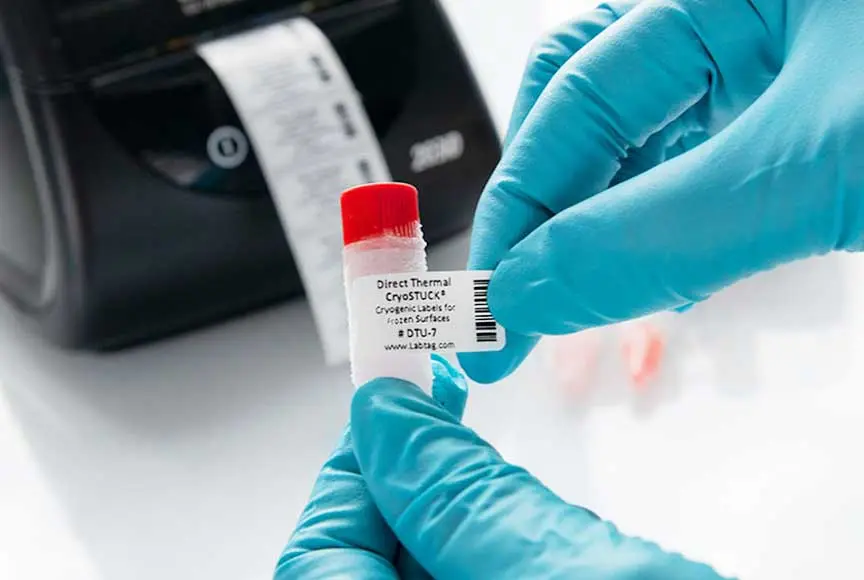

how do direct thermal labels work?

Direct thermal printing is a technology that uses thermal paper and a thermal print head to print. In the direct thermal printing process, the print head heats the thermal paper at specific locations, producing high-quality, clear images that are ideal for printing barcodes, graphics, and text. While advantageous in many scenarios, it is not suitable for labels and images that require long-term durability, high levels of water or chemical resistance. Because thermal print output is affected by light, heat and friction, labels under these conditions may become illegible due to discoloration or blurring.

how do thermal transfer labels work?

what are thermal labels used for?

· Logistics and transportation: Self adhesive thermal labels play a key role in the logistics and transportation fields. They are used to print express tracking numbers, package labels and shipping identification, ensuring accurate tracking and delivery of packages and goods, improving the efficiency and accuracy of logistics operations.

· Healthcare: The healthcare industry uses thermal adhesive labels to identify medical records, pharmaceuticals and medical equipment. These labels not only help manage and identify patient information, they also ensure accurate medication tracking and medical device usage records.

· Food and Beverage: In the food industry, thermal food labels are commonly used for batch traceability, product information and nutritional labeling on packaging. They remain visible in a variety of environmental conditions, ensuring food safety and compliance.

· Manufacturing: The manufacturing industry use thermal sticker label to identify products and parts for process control and inventory management. These labels can be printed and applied quickly, helping to increase productivity and reduce errors.

Thermal labels

Thermal labels