Thermal Printing Labels: An In-Depth Guide to Applications, Types, and Benefits

Thermal printing labels have revolutionized industries requiring efficient and high-quality labeling solutions. From logistics to healthcare, thermal labels are widely recognized for their durability, clarity, and cost-effectiveness. In this comprehensive guide, we’ll explore the world of thermal printing labels, their applications, types, and the factors to consider when choosing the right labels for your needs.

Understanding Thermal Printing Labels

Thermal printing labels are produced using heat-sensitive materials and specialized printers. Unlike traditional ink-based printing, thermal printing relies on heat to create an image, making it faster, more cost-effective, and less prone to smudging. The technology is ideal for creating labels used in shipping, retail, healthcare, and various other sectors.

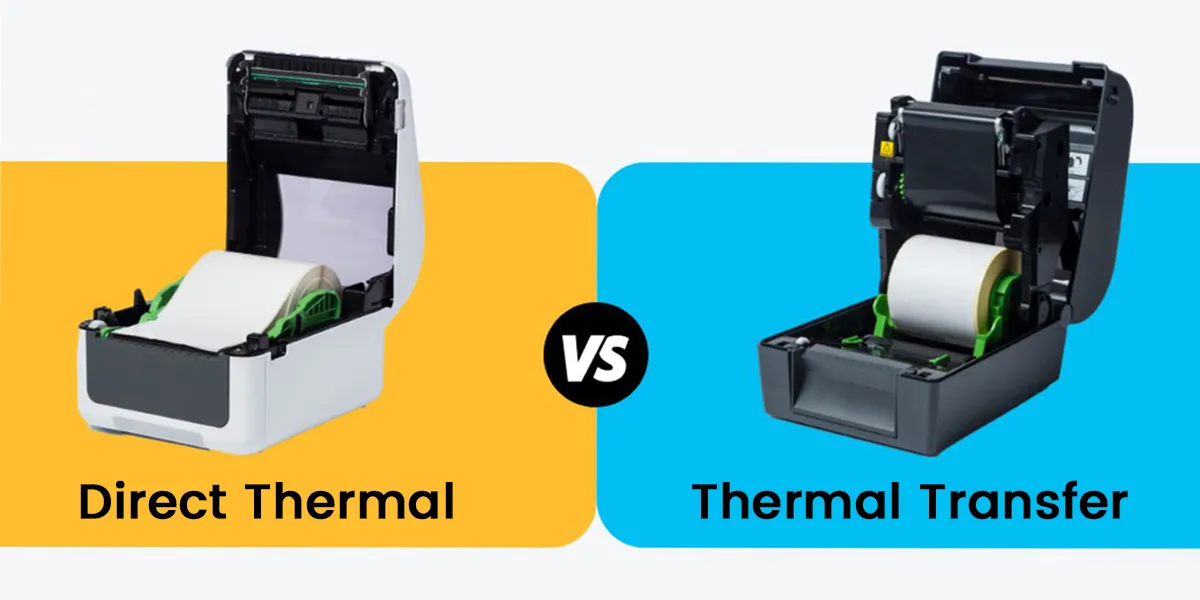

How Does Thermal Printing Work?

Thermal printers use heat to activate the dye in the label material. There are two types of thermal printing:

1.Heat-sensitive paper: which darkens when heated, is used in the direct thermal printing process. Direct thermal labels, such as 4x6 direct thermal labels, are commonly used for shipping and barcodes but are susceptible to fading under extreme conditions.

2.Thermal Transfer Printing: This technique uses a heated ribbon to transfer ink onto the label material, making it more durable and resistant to environmental factors.

Applications of Thermal Printing Labels

Thermal printing labels are versatile and used across numerous industries. Below are key sectors benefiting from these labels:

1. Shipping and Logistics

Thermal shipping labels, especially 4x6 thermal labels, are the backbone of logistics operations. Their ability to produce clear, scannable barcodes ensures efficient tracking and delivery. Whether it’s thermal shipping labels 4x6 or custom-sized labels like 6x4 thermal labels, the logistics industry relies heavily on thermal technology.

2. Retail and Inventory Management

Thermal labels, such as 2 x 3 thermal labels, streamline inventory tracking and product labeling in retail. Their durability and ease of use make them perfect for barcodes, price labels, and product descriptions.

3. Healthcare and Pharmaceuticals

In the healthcare sector, pharmacy thermal labels and prescription thermal labels ensure accurate patient information and medication tracking. Thermal labels are ideal for environments where precision and clarity are critical.

4. Industrial and Manufacturing

Industries use industrial direct thermal labels for labeling equipment, parts, and packages. These labels can withstand harsh conditions, including heat, moisture, and abrasion.

Thermal printing technology has become a cornerstone for industries requiring efficient labeling solutions. From logistics to healthcare, thermal labels offer unparalleled clarity and durability. Among these, 4x6 direct thermal labels, BPA-free thermal labels, pharmacy thermal labels, and prescription thermal labels serve as vital tools tailored for specific needs.

1. The Versatility of 4x6 Direct Thermal Labels

The 4x6 direct thermal labels are among the most widely used label sizes, especially in shipping and logistics. Their dimensions make them ideal for printing shipping addresses, barcodes, and other essential data required for packages. Direct thermal printing eliminates the need for ribbons or ink, reducing operational costs and ensuring a quick, efficient printing process.

However, direct thermal labels are best suited for short-term use as they can fade when exposed to heat or sunlight. Despite this limitation, they remain indispensable for businesses prioritizing high-speed and cost-effective labeling solutions.

2. Safer Choices with BPA-Free Thermal Labels

Health and environmental concerns have led to the increased demand for BPA-free thermal labels. BPA (Bisphenol A) is a chemical often used in the production of thermal paper but has raised safety concerns due to its potential effects on human health. Businesses in sectors like food packaging, retail, and healthcare are transitioning to BPA-free alternatives to ensure compliance with safety standards and provide a safer end product to consumers.

These labels offer the same efficiency and quality as traditional thermal labels but with the added assurance of being free from harmful chemicals. They’re particularly suitable for industries where safety and environmental impact are paramount.

3. Specialized Pharmacy Thermal Labels

In the healthcare sector, accurate and reliable labeling is critical. Pharmacy thermal labels are designed to meet the specific needs of pharmaceutical environments. These labels are used to print vital information such as medication instructions, dosage details, and patient identifiers.

Thermal technology ensures that the text is sharp and easy to read, reducing the risk of errors in medication administration. Additionally, pharmacy labels often require strong adhesive properties to ensure they remain securely attached to bottles or packaging, even under varying conditions.

4. Precision with Prescription Thermal Labels

A subset of pharmacy labels, prescription thermal labels, plays a crucial role in the distribution of medications. These labels must be durable, legible, and resistant to smudging to prevent any misinterpretation of critical medical information. Prescription labels often include barcodes for tracking and compliance purposes, making thermal printing an ideal choice for producing high-quality labels quickly and cost-effectively.

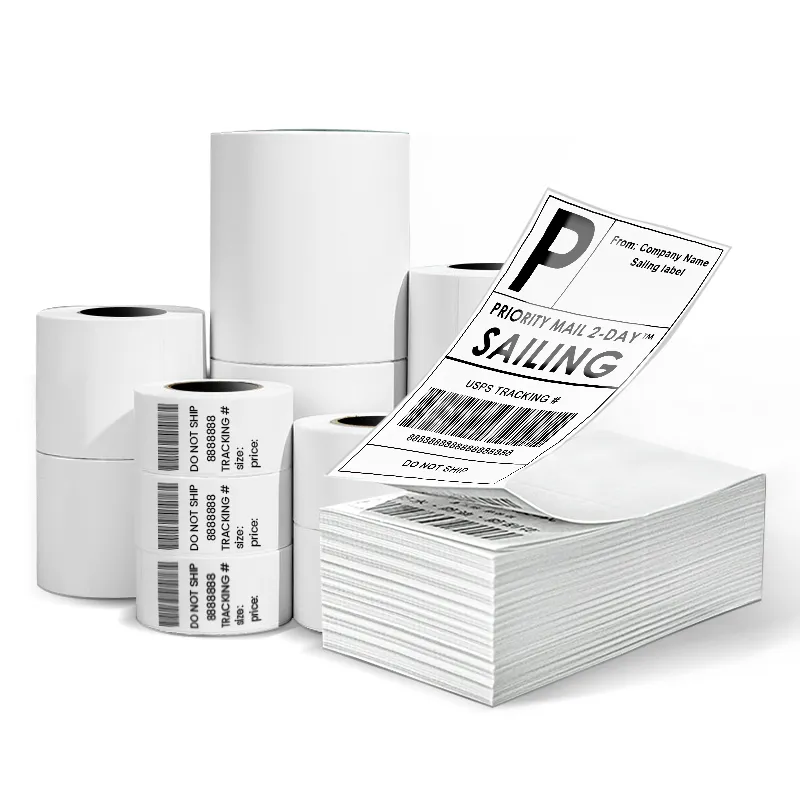

Types of Thermal Printing Labels

Choosing the right thermal printing label involves understanding the variety available and their specific applications. Here’s a breakdown of popular types:

1. Adhesive Types

● Removable Adhesive Thermal Labels: These labels can be easily removed without leaving residue, making them suitable for temporary applications like pricing or promotional tags.

● Permanent Adhesive Labels: Ideal for long-term use, these labels provide a strong bond to various surfaces.

2. Size Options

Thermal labels come in multiple sizes to cater to different needs:

● 4x6 Thermal Labels: Standard size for shipping and logistics.

● 2x1 Thermal Labels: Commonly used for smaller items like retail products.

● 6x4 Thermal Labels: Used for larger packages requiring more detailed information.

3. Material Types

● Clear Thermal Labels: Provide a transparent and sleek finish, often used for branding or aesthetic purposes.

● Colored Thermal Labels: Available in various colors for organizational and decorative purposes.

● Waterproof Thermal Printer Labels: Designed to withstand moisture, making them ideal for outdoor and industrial applications.

4. Specialty Features

● BPA-Free Thermal Labels: Safe for food packaging and environments where BPA exposure is a concern.

● Are Thermal Labels Waterproof?: Many thermal labels, especially waterproof variants, resist smudging and degradation when exposed to liquids.

BPA-free thermal labels are a safer alternative for industries concerned with health and environmental impacts, offering the same high-quality printing without the risks associated with Bisphenol A. These labels are ideal for food packaging, retail, and healthcare applications, ensuring compliance with safety standards while maintaining durability and clarity.

Benefits of Thermal Printing Labels

Thermal labels offer several advantages, including:

● Cost-Effectiveness: No need for ink or toner reduces costs significantly.

● Speed and Efficiency: Thermal printers, like those used for thermal printer label production, operate quickly, enabling high-volume printing.

● Durability: Labels such as waterproof thermal printer labels and direct thermal labels 4x6 are resistant to wear and tear.

● Clarity: Barcodes and shipping labels depend on crisp, clear text and graphics, which thermal technology guarantees.

Factors to Consider When Choosing Thermal Printing Labels

When selecting the right labels, consider the following:

1. Application Requirements

Determine the specific use of the labels. For shipping, 4x6 thermal shipping labels are ideal, while pharmacy thermal labels work well in healthcare settings.

2. Environmental Conditions

Think about whether the labels will be in contact with chemicals, dampness, or extremely high or low temperatures. Use industrial direct thermal labels or waterproof thermal labels for outdoor applications.

3. Printer Compatibility

Ensure that your labels are compatible with your thermal printer. Labels like 4x6 labels thermal are widely compatible with standard shipping label printers.

4. Adhesive Type

Choose between removable or permanent adhesive labels based on whether the labels need to be reusable or long-lasting.

5. Safety Standards

For applications involving food or healthcare, ensure the labels are BPA-free thermal labels to meet safety regulations.

Thermal Printing Label Innovations

The thermal label industry continues to innovate with new materials and features:

● Eco-Friendly Options: Sustainable materials for environmentally conscious businesses.

● Custom Shapes and Sizes: Catering to unique business needs with options like 2x1 thermal labels and 6x4 thermal labels.

● Enhanced Durability: Advanced materials for creating waterproof thermal printer labels and labels resistant to extreme conditions.

Conclusion

Thermal printing labels are indispensable in today’s fast-paced industries. Whether you’re managing shipping logistics with 4x6 direct thermal labels, organizing inventory with colored thermal labels, or ensuring compliance in healthcare with pharmacy thermal labels, there’s a thermal label to meet your needs. By understanding the types, benefits, and applications of thermal labels, businesses can choose the best solutions for efficient and reliable operations.

Investing in quality thermal printing labels and printers not only enhances productivity but also ensures lasting durability and clarity. Explore the wide range of thermal label options and take your labeling operations to the next level.

Feel free to contact us if you're interested in this product!

Thermal labels

Thermal labels