What Are Industrial Thermal Transfer Labels, and Why Do They Matter?

How is it that industries maintain the character of their labels irrespective of threats to their integrity? To put it simply, industrial labeling causes accuracy, long-lasting labels, and most importantly, efficiency. An array of industries employs industrial thermal transfer labels. These labels produce a print that has an excellent life span. In this article, we’ll distinguish between what are actually industrial thermal transfer labels and how they are any different from direct thermal labels. Most importantly, why they are used. Different materials, sizes and printing equipment will also be covered. Discover why SailingPaper is the right partner for your labeling needs.

An Overview of Industrial Thermal Transfer Labels

What are Industrial Thermal Transfer Labels?

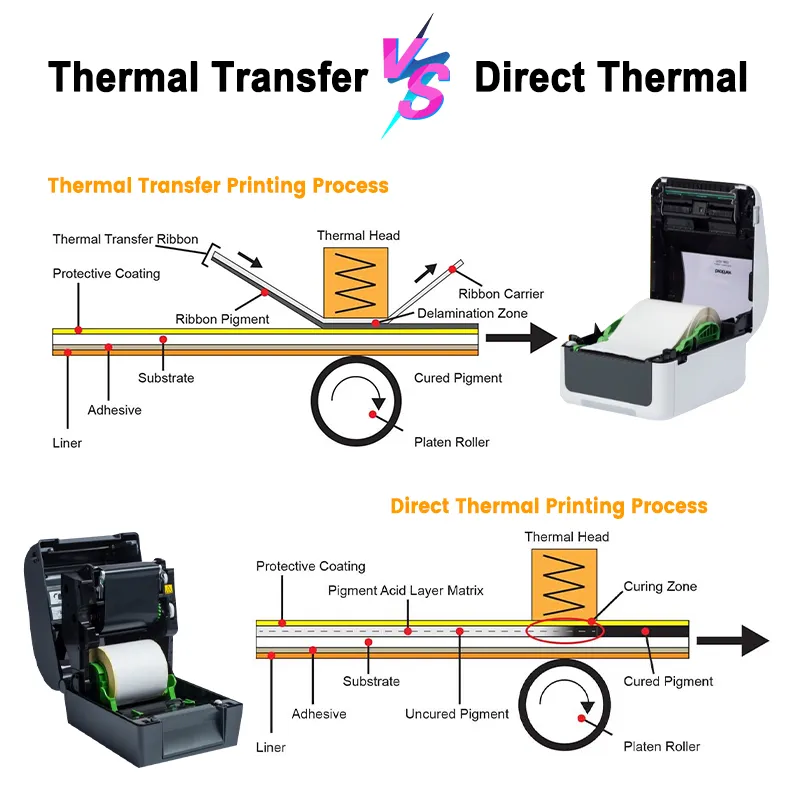

Heat prints from a ribbon Industrial thermal transfer labels. The printhead applies the temperature on the ribbon to press the image to the label which is made of wax or resin. High-quality images can be produced. These labels do not easily wipe away or wear out. Thermal transfer printing is favorable to industries in which the label has to withstand expansive conditions. Pre printed thermal labels find tremendous application where there exists a need for constant design. Only specific variable information like the barcode or the shipping information needs to be printed.

Comparison with Direct Thermal Labels

Direct thermal labels have no ribbon. These labels have a coating that is activated under heat. On the other hand direct thermal labels are cheap to manufacture and quicker to produce than the prior, but they are not as tough as their counterparts. Direct thermal labels will, in time, become faded because of sunshine or heat, especially when the coating is not well laid out. The direct thermal label lifespan is significantly shorter compared to thermal transfer labels, which remain intact for much longer under harsh conditions. In industries where durability of the label is of a significant concern, thermal transfer labels are the best fit for the job.

Categories and Sizes of Industrial Thermal Labels

Industrial thermal transfer labels are manufactured to be used in different industries and in different application areas, and hence they are also available in a variety of sizes. Some of these are:

Common Sizes

- 4 x 6 direct thermal labels: These are widely applied for shipments, inventory tags and barcodes since these labels are easy to use and compact. It can easily accommodate necessities such as essential information by fitting in with most packaging styles.

- 4 x 2 thermal transfer labels: If you are looking to inventory fertile grounds for smaller items, these labels would suffice as they are ideal. These labels complement Manage for compact areas or inventory decors.

- 4 x 8 direct thermal labels: This tag is used mainly for shipping bulk weight of items. These tags also provide generous space to impart detailed information about the items.

- 4 x 3 direct thermal labels: These Labels are a great choice if you want to use them for retail purposes or for sending smaller parcels. This size is ideal for use as product labels or item tracking barcodes.

- 4x6 direct thermal shipping labels: This size seems adequate with using it for addresses, bar codes and tracking numbers for shipping as it’s the most commonly used size.

There are 4 x 6 thermal label roll and 4 x 6 thermal transfer labels perforated available in the market that are ideally suited for large quantities of bulk printing. Perforated strip labels are easy to separate - by hand, without printing over them.

Material Options for Thermal Transfer Labels

Turnkey labels that work with thermal transfer technology require a thermal transfer ribbon printer for efficient label creation. The factors which affect the working of thermal transfer labels are the thermal transfer ribbon, printers, and label material.

- Polyester Thermal Transfer Labels:

These offer high warmth, moisture, and chemical, temperature, and moisture resistance. This feature makes polyester thermal transfer labels suitable for industrial use, as industrial labels last longer.

- Durability and Resistance:

Other materials, such as vinyl and polypropylene, have increased durability and resistance to fading abrasion and water, making it ideal for items that will undergo rough handling or extreme conditions.

- Color Thermal Transfer Labels:

For businesses where branding is important, color thermal transfer labels work well. Product packaging made with these labels will include logos and bright designs and get extra presentation. Color thermal printer labels are useful for differentiation and visibility as well.

- Waterproof Thermal Labels:

High moisture levels call for the use of waterproof thermal labels. While waterproof thermal transfer labels exist, standard waterproof labels will not do. Because these labels survive water damage, they can be used in industries such as food processing, outdoor settings, and so on. SailingPaper provides reliable and water-resistant thermal printer waterproof labels that are efficient for extreme conditions.

Thermal Transfer Labels and Their Applications

In logistics, retail, and manufacturing industries, thermal transfer labels are the most common method of labelling products.

Role in Shipping and Logistics, Etc

In shipping and logistics, these labels act to track, barcodes, and shipping labels. Its durability ensures that the labels remain legible as they are exposed to various conditions. In inventory management, products are monitored using thermal labels 4 x 6, which are barcodes or serial numbered but readable. In industrial applications, they can mark engineering tools and diagramable assets, label machinery, and withstand chemicals, abrasion, and heat.

Usage in Retail

There is a trust that exists in thermal transfer labels in order to obtain accurate product identification that aids in the retail industry. Thermal transfer is often used for product and barcode tagging as well as switching price tags. This ensures that not only do stores but warehouses as well work more proficiently and improve their customer experience.

Applications in Manufacturing

Thermal Transfer labels across manufacturing are often used for asset tracking, tool identification and machinery labeling. The identification labels are able to withstand harsh conditions like extreme temperature and chemical exposure, which makes them ideal for tough industrial usages.

Versatility Across Industries

Across many industries, thermal transfer labels prove to be a perfect solution for tracking and even labeling. Strong as well as durable, these labels are equipped to be used in logistics, and retail. A business's basic requirement is having a clear and legible label that does not get damaged, and thermal transfer labels solve that problem.

Thermal transfer labels vs direct thermal labels

When comparing and contrasting thermal transfer labels to direct thermal labels, clear distinctions can be made:

- Cost: Direct thermal labels can be seen as cost efficient, but they can have a much shorter lifespan, which leads to increased costs.

- Durability: Thermal transfer labels are a clear winner in durability as they are waterproof, shatterproof and chemical resistant, allowing them to be effective throughout the years.

- Printer Compatibility: Thermal transfer printers require the use of a ribbon whereas direct thermal printers do not, ultimately making direct thermal printers more simple and efficient.

For industries that require strict durable labels to be printed, thermal transfer labels would be the most appropriate option.

Printing Systems and Accessories

It is important to use the right thermal printer for good quality prints. In choosing the best thermal printer shipping labels, remember the specific label material and size suitable for your company. With the best printing machine, one can get better prints that last long. When looking for color thermal printer labels, make sure the printer is capable of color printing as well. These types of labels are used for branding as well and need to be clear and sharp when printed.

Maintenance schedules for printers and printer labels must also be strictly followed to ensure a longer lifespan of these items. Issues such as printer issues can be eliminated by cleaning the printhead and adjusting some settings.

Specialty Waterproof Thermal Labels

Are thermal printed labels waterproof?

All thermally printed labels are not waterproof. However, there are some which are made intending to be moisture resistant; some heated labels will be waterproof. Waterproof thermal labels can be used in the food, beverage and even outdoor industries.

Thermally Printed Waterproof Labels Needed in Extreme Conditions

Thermal printer waterproof labels are required in extreme conditions. These labels are resistant to water, chemicals and extreme temperatures. In many situations, these labels can still identify items, making them ideal for the food industry, logistics, and outdoor products.

Exploring Applications of Thermal Label Stock

Using the right thermal label stock material is key to meeting performance and durability requirements. If the label is meant for outdoor application, materials like polyester thermal transfer labels or vinyl can be utilized, since these offer the required resistance to extreme conditions.

SailingPaper offers multiple thermal label stock options that cover specific classes of application, ensuring that the best performance and durability of your labels is achieved.

Final Thoughts

In conclusion, Thermal transfer labels are crucial for any industry where strong and long-lasting prints are needed. They are efficient at shipping, inventory, or product labeling, since they are reliable. They can survive in extreme conditions and are enduring and legible.

When purchasing thermal transfer labels, it is best to think of the dimensions, material, and type of printer that you will need. Sailingpaper, for instance, has lots of solutions such as 4 x 6 thermal transfer labels, color thermal printer labels, and more. For specialty labels, such as waterproof options, SailingPaper can offer comprehensive help.

FAQs

Q1: What Are Thermal Transfer Labels Used For?

Shipping, inventory, and product labeling that require long-lasting labels make use of thermal transfer labels.

Q2: Is it true that thermal transfer labels are waterproof?

Waterproof options do exist, however, standard thermal transfer labels are more vulnerable to water hybridization.

Q3: Please explain the difference between a direct thermal label and a thermal transfer label?

Compared to direct thermal labels, which are cheaper and easy to find but fade with time, direct thermal labels have a longer lifespan and are more resilient.

Get in touch with us

If industrial labeling is what you are up for then SailingPaper is definitely the one to go for. From color thermal printer labels to industrial thermal transfer labels, we provide a plethora of options at our disposal.

Looking for help and guidance on 4 x 6 thermal transfer labels? No problem. We provide a huge assortment of products which can easily cater to all your labeling needs. Get in touch with us immediately.

Thermal labels

Thermal labels