ODM Thermal Paper Manufacturing Process Quotes & OEM Exporter Pricelist

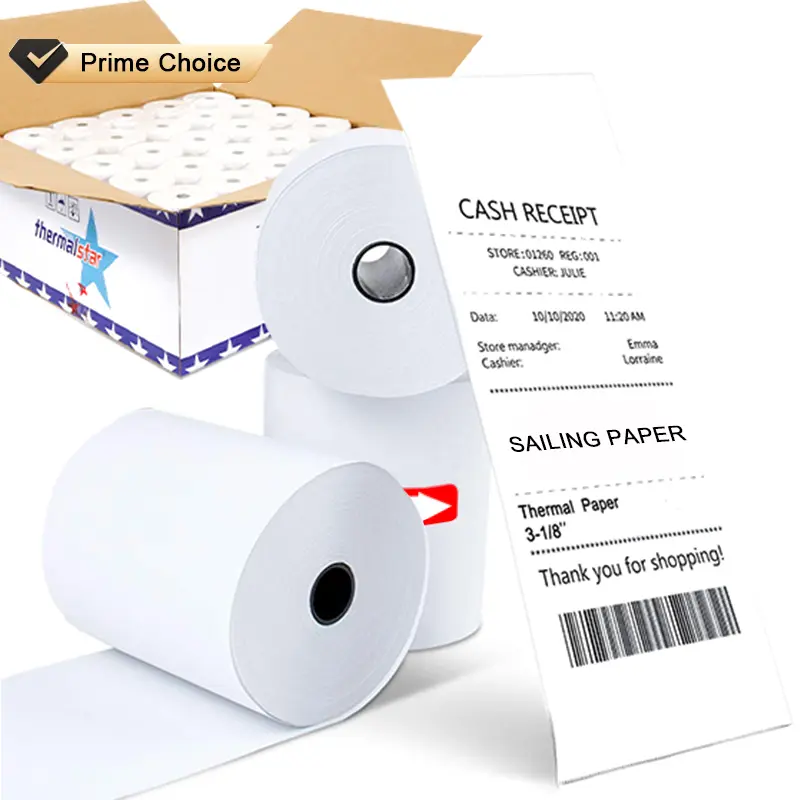

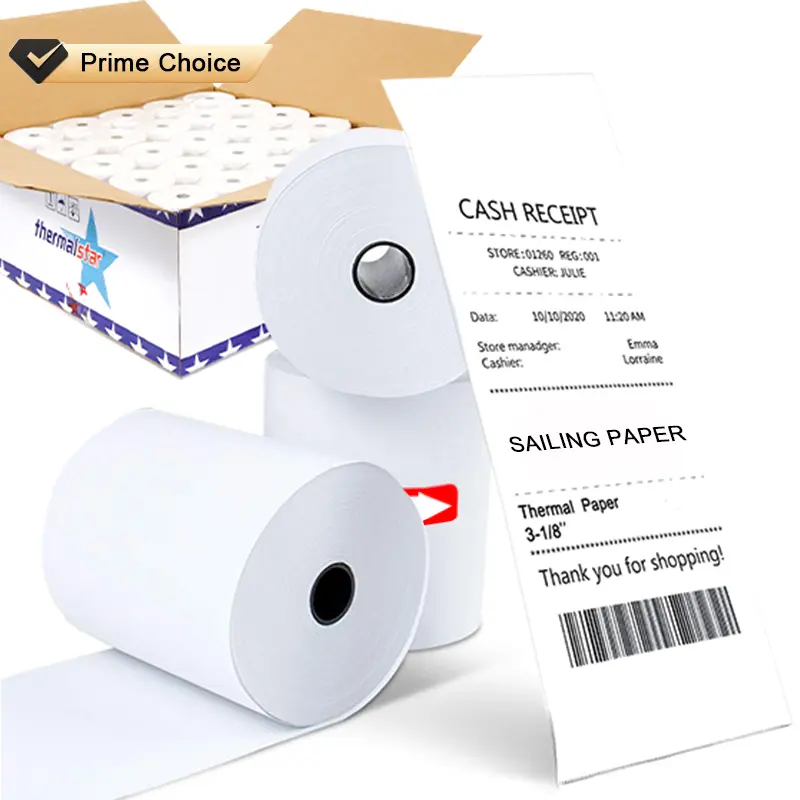

At ShenZhen Sailing Paper Co., Ltd., we specialize in high-quality ODM thermal paper manufacturing tailored to your specific requirements. Our efficient production process utilizes premium materials to ensure durability and performance that meet international standards. As a leading exporter, we prioritize timely delivery and dependable products. Our experienced team is ready to assist you throughout the entire journey, from design to production. With competitive pricing and customizable options, we simplify the process for B2B purchasers seeking the ideal thermal paper solutions. Contact us today to learn how we can elevate your business with our top-notch offerings!

Tips & Tricks for ODM Thermal Paper Manufacturing Process Quotes Winning in 2025 Stands Out

In the rapidly evolving landscape of thermal paper manufacturing, standing out in the competitive arena requires strategic insights and innovative approaches. As we head into 2025, navigating the ODM (Original Design Manufacturer) market calls for a deep understanding of both sourcing strategies and technical excellence. At Sailing, we have honed our expertise since our establishment in 2011, transitioning from a local paper converter to an international player with production bases in China and Malaysia. This diverse operational footprint enables us to meet the unique demands of global buyers while ensuring high-quality standards.

To secure winning quotes in the ODM thermal paper manufacturing process, it's crucial to focus on quality assurance and technological advancements. Buyers should prioritize manufacturers who not only possess the necessary certifications but also showcase a commitment to sustainable practices. Additionally, engaging with suppliers who leverage the latest innovations in printing technology can significantly enhance the overall product offering. At Sailing, we pride ourselves on our ability to blend traditional craftsmanship with modern techniques, ensuring that our thermal paper products meet high performance requirements and customer satisfaction.

Building strong partnerships with suppliers can also provide significant value. As you prepare for 2025, consider establishing open lines of communication with your manufacturing partners to explore co-design opportunities and tailor products to specific market needs. By collaborating closely and aligning on expectations, you’ll not only obtain competitive quotes but also integrate solutions that resonate with your target audience. At Sailing, our commitment to customer-centric service ensures that we go beyond mere transactions; we aspire to be partners in your success, delivering innovative solutions that help your business thrive in the global marketplace.

| Dimension | Value |

|---|---|

| Average Production Cost per Roll | $0.25 |

| Annual Production Volume | 10,000,000 rolls |

| Lead Time for Manufacturing | 2-4 weeks |

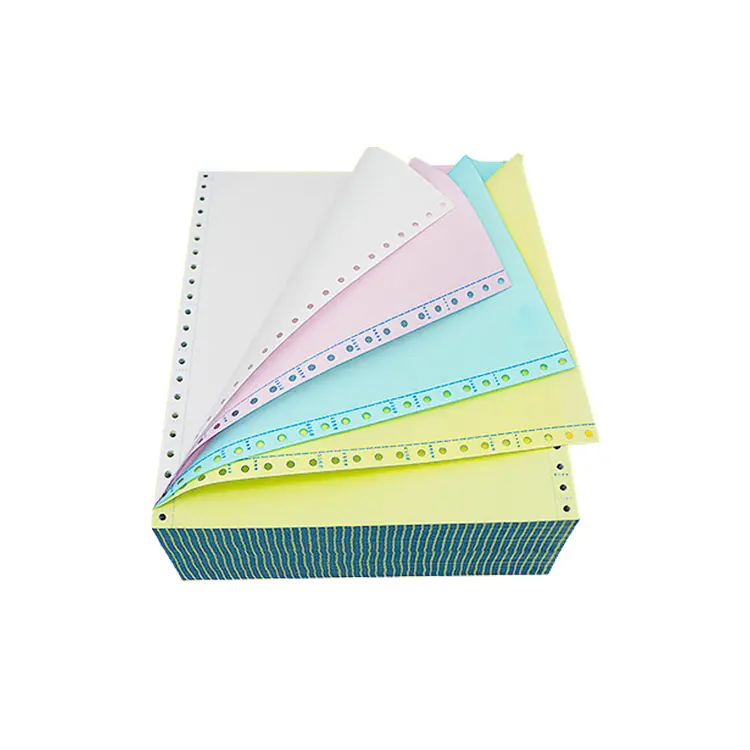

| Materials Used | Woodfree Paper, BPA-free Coating |

| Average Quote Response Time | 24 hours |

| Quality Assurance Standards | ISO 9001 |

| Sustainability Practices | Recycled Materials, Eco-friendly Inks |

| Expected Growth Rate | 5% annually |

Finding Your Perfect Match ODM Thermal Paper Manufacturing Process Quotes Now Trending Factory

C

Christopher Lee

Fantastic product! The support team demonstrated a high level of professionalism and expertise.

12

June

2025

J

James Rivera

This product exceeded my expectations! The after-sales representatives were very well-informed.

15

May

2025

N

Natalie Turner

Great purchase! The quality is excellent and the service staff is incredibly professional.

17

May

2025

W

Wyatt Anderson

Impressive quality! The dedication shown by the customer support team was commendable.

06

June

2025

L

Liam Diaz

The product quality is exceptional! The after-sales support was quick and very helpful.

06

May

2025

I

Isabella Johnson

Thrilled with my order! The quality is excellent, and the staff’s professionalism is outstanding.

29

June

2025

Thermal labels

Thermal labels