ODM Thermal vs. Laser Labels: Guide to Selecting the Best OEM Products for Factories

When comparing ODM Thermal and Laser Labels, it's crucial to recognize the distinct advantages of each. As a business owner, I prioritize factors such as cost efficiency, print quality, and supplier reliability. ODM labels are excellent for businesses in need of tailored solutions, while laser labels provide superior resolution for eye-catching designs. I've collaborated with ShenZhen Sailing Paper Co., Ltd. for my labeling requirements, and their commitment to quality and service is exceptional. Their experienced team understands our specific needs, simplifying the decision-making process.Expert Tips For ODM Thermal Vs Laser Labels Products Outperforms the Competition

When it comes to choosing the right labeling solution for your products, understanding the differences between ODM thermal labels and laser labels is crucial for staying competitive in today’s global market. Since our foundation in 2011, Sailing has positioned itself as a leader in the production of high-quality printing and packaging consumables, with facilities in both China and Malaysia. This strategic location allows us to leverage advanced technologies and streamlined logistics to deliver exceptional results tailored to our clients' needs.

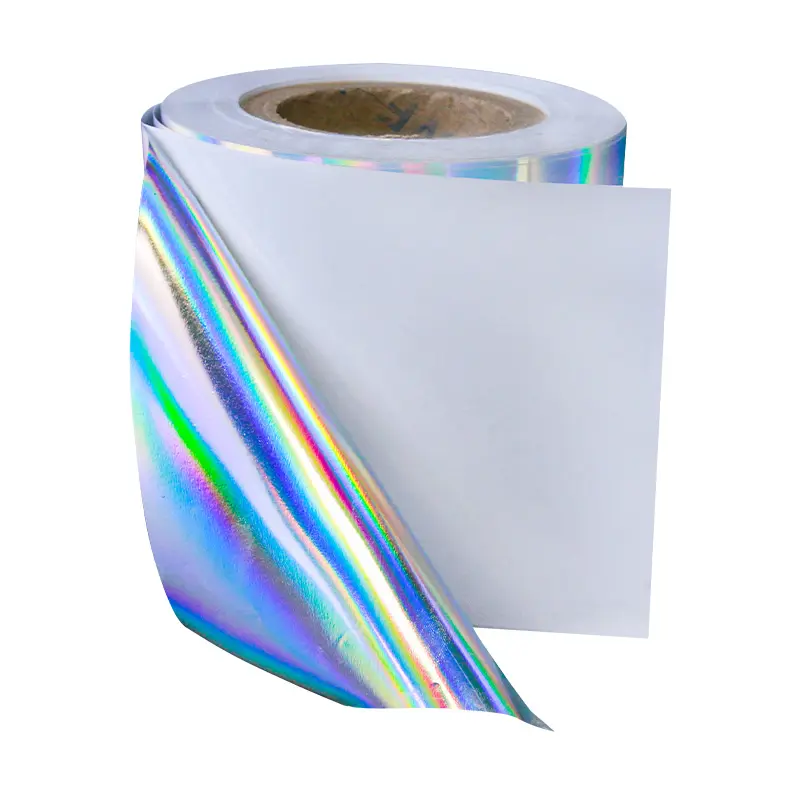

ODM thermal labels offer significant advantages for businesses focused on efficiency and cost-effectiveness. They are produced on-demand, allowing for customization that meets specific branding and regulatory requirements without excessive lead time. Additionally, thermal labels are compatible with various printing systems and can produce sharp, durable prints that withstand various environmental conditions. These features make ODM thermal labels ideal for industries that require quick turnaround and flexibility, such as retail and logistics.

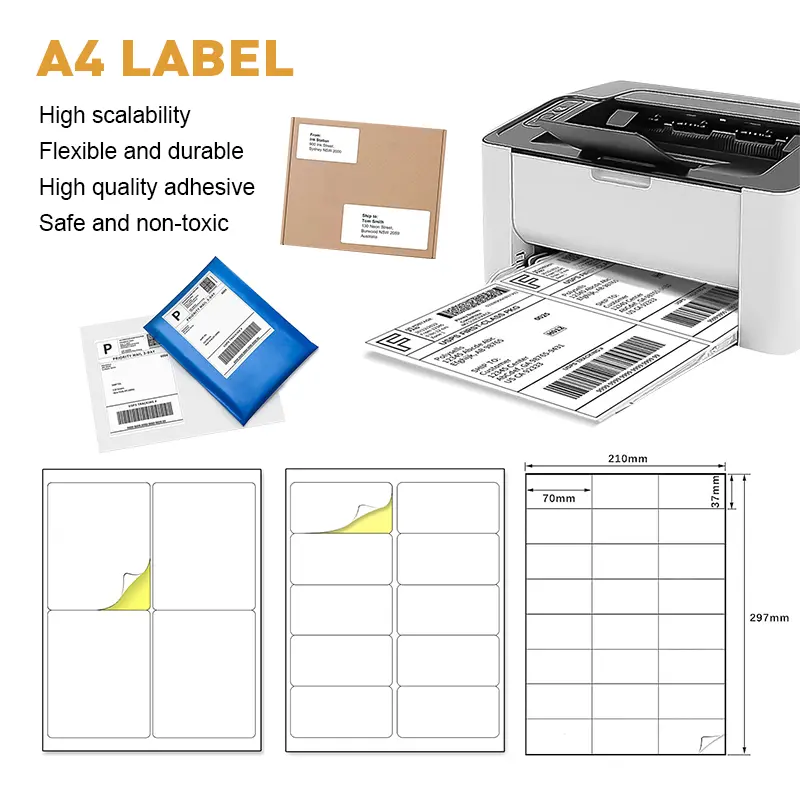

On the other hand, laser labels typically shine in high-volume printing scenarios where quality and resolution are paramount. They provide crisp text and images, making them suitable for professional applications that necessitate a polished presentation. Furthermore, laser labels are resistant to smudging and fading, ensuring longevity. Understanding whether your business requires the agility of ODM thermal labels or the premium quality of laser labels is key to outperforming the competition. Sailing is here to partner with you in navigating these choices, offering unparalleled expertise and innovative solutions tailored to your unique requirements.

Expert Tips For ODM Thermal Vs Laser Labels Products Outperforms the Competition

| Label Type | Cost per Label ($) | Print Quality | Durability | Speed (labels/min) |

|---|---|---|---|---|

| Thermal Transfer | 0.05 | High | Excellent | 100 |

| Direct Thermal | 0.03 | Medium | Fair | 80 |

| Laser Labels | 0.10 | Very High | Good | 60 |

| Inkjet Labels | 0.15 | Medium | Fair | 50 |

Step-by-Step Guide To ODM Thermal Vs Laser Labels Manufacturers You Can Rely On Service

D

Daniel Martinez

The product quality is outstanding. Their team’s expertise makes the entire experience smooth and efficient.

22

June

2025

O

Oliver Young

Truly exceptional product! The staff is knowledgeable and their support service is top-tier.

05

July

2025

Z

Zachary Cole

This product speaks for itself in terms of quality. The support was insightful and very attentive.

22

June

2025

L

Lily Torres

Superb quality! Customer support was prompt and professional, making the buying process easy.

31

May

2025

I

Isabella Johnson

Thrilled with my order! The quality is excellent, and the staff’s professionalism is outstanding.

29

June

2025

L

Liam Thomas

Really top-quality product! The after-sales service was quick and very professional.

29

May

2025

Thermal labels

Thermal labels