OEM Thermal Transfer Labels for Direct Thermal Printers Made in China

Searching for premium OEM thermal transfer labels optimized for direct thermal printers? High-quality products from trusted manufacturers are essential for B2B purchasers who demand reliability. Our thermal transfer labels are engineered for seamless compatibility with direct thermal printers, delivering sharp, clear prints for all your labeling tasks. Experience enhanced productivity with durable labels that withstand various conditions. Perfect for industries like retail and logistics, these labels cater specifically to your operational needs. Choosing OEM thermal transfer labels guarantees quality and dependability. Elevate your labeling strategy by partnering with established suppliers who understand your business's unique demands.

10 Essential Tips For OEM Can Thermal Transfer Label Be Printed On Direct Thermal Printer Manufacturers Application Delivers Unmatched Quality

When it comes to enhancing your business’s branding and efficiency, choosing the right labeling technology is crucial. Thermal transfer labels (TTL) have gained popularity due to their durability and high-quality print output. However, many manufacturers in the OEM sector often wonder if these labels can be printed using a direct thermal printer. The answer is yes, but there are vital considerations to ensure optimal results.

As a leader in printing solutions since 2011, Sailing has forged a global presence with state-of-the-art production facilities in China and Malaysia. Our extensive experience in printing, packaging, and logistic consumables enables us to provide essential tips for OEM manufacturers looking to achieve unmatched quality with their labeling applications. First, understand the material compatibility of your labels and printers. Direct thermal printers are best suited for thermally sensitive materials, which may not withstand long-term exposure compared to thermal transfer labels. Consider your application needs—products that require durability and resistance to environmental elements might benefit significantly from using our high-quality TTL.

Additionally, investing in robust materials from a reliable supplier like Sailing can significantly streamline your production process. Our commitment to quality ensures that our labels deliver consistent performance across various environments. Confidence in your labeling solutions not only enhances product appearance but also strengthens your brand on the global stage. By leveraging the insights shared above, OEM manufacturers can optimize their labeling practices and ensure remarkable quality that resonates with consumers worldwide.

10 Essential Tips For OEM Can Thermal Transfer Label Be Printed On Direct Thermal Printer Manufacturers Application Delivers Unmatched Quality

| Tip Number | Tip Description | Recommended Actions |

|---|---|---|

| 1 | Choose the Right Label Material | Opt for materials compatible with direct thermal printing. |

| 2 | Adjust Printer Settings | Configure DPI and speed settings for optimal results. |

| 3 | Conduct Regular Maintenance | Ensure print head and rollers are clean for quality output. |

| 4 | Test Printing Before Production | Perform test prints to check for alignment and quality. |

| 5 | Use Quality Thermal Transfer Ribbons | Choose ribbons specifically made for thermal transfer printing. |

| 6 | Ensure Sufficient Printer Memory | Upgrade if necessary to handle complex graphics. |

| 7 | Regularly Update Printer Firmware | Check for updates to improve performance and features. |

| 8 | Monitor Environmental Conditions | Keep printing area stable in temperature and humidity. |

| 9 | Train Operators | Provide training on proper label printing techniques. |

| 10 | Seek Expert Advice | Consult with professionals for advanced solutions. |

Why Opt For OEM Can Thermal Transfer Label Be Printed On Direct Thermal Printer Manufacturers Custom Solutions, Outperforms the Competition

M

Michael Brown

I was impressed by the attention to detail in this product. Their after-sales service was nothing short of exemplary.

19

May

2025

L

Lucy Thompson

I am extremely satisfied! The service staff displayed remarkable professionalism and skill.

02

July

2025

H

Henry Williams

Top-notch quality! I appreciate how professional and prompt their service team has been.

03

June

2025

E

Ella White

Exceptional quality! Their support team after purchase was very friendly and knowledgeable.

05

July

2025

L

Logan Taylor

Just perfect! The quality of the product and the efficient service were truly commendable.

05

June

2025

E

Elijah Anderson

Amazing product quality! Their service team went above and beyond to assist me.

13

May

2025

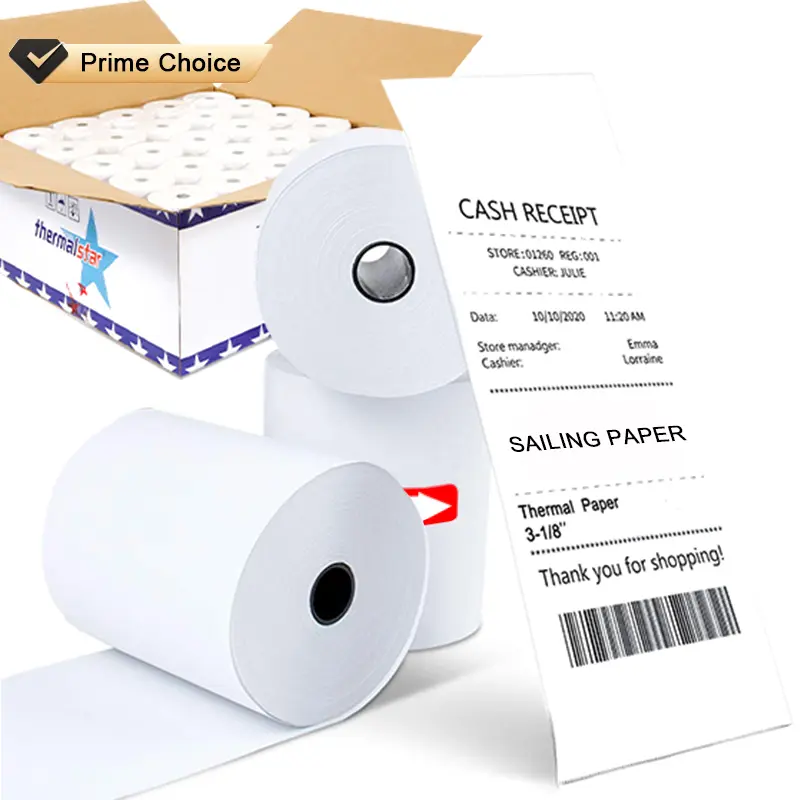

Thermal labels

Thermal labels