OEM Fluorescent Thermal Labels Manufacturer - Wholesale Options Available Now

As a premier manufacturer of OEM fluorescent thermal labels, I understand the unique requirements of your business. Our high-quality thermal labels are designed to enhance your brand's visibility and deliver exceptional durability. At ShenZhen Sailing Paper Co., Ltd., we specialize in creating vibrant labels customized to your specifications. With a focus on outstanding service and quality, your satisfaction is my top priority. Let's collaborate to meet your labeling needs with the perfect solutions tailored just for you!Methods To OEM Fluorescent Thermal Labels Manufacturer Industry Giant Factory

In the ever-evolving landscape of manufacturing, businesses are increasingly seeking reliable partners for OEM (Original Equipment Manufacturer) services, particularly when it comes to fluorescent thermal labels. Since our inception in 2011, Sailing has transformed from a regional paper converter into a prominent international group with manufacturing facilities in both China and Malaysia. Our commitment to quality and efficiency in the production of printing, packaging, and logistic consumables has positioned us as a leading choice for global buyers in need of OEM solutions.

The fluorescent thermal label market is witnessing a surge in demand, driven by advancements in technology and an expanding scope of application across various industries. With robust production capabilities, we specialize in providing high-performance thermal labels that stand out for their durability and vibrant visibility. Our state-of-the-art manufacturing processes, coupled with a firm adherence to international quality standards, ensure that each label not only meets but exceeds client expectations. By partnering with Sailing, clients can leverage our expertise and facilities, translating into competitive advantage in their respective markets.

At Sailing, we prioritize collaboration with our clients, offering bespoke solutions tailored to specific needs and preferences. Our dedicated teams work closely with global procurement agents to ensure seamless integration of our products into their supply chains. With a proactive approach to customer service and a focus on innovation, we are committed to helping businesses thrive in the dynamic world of logistics and packaging. Let us be your trusted partner in navigating the complex landscape of OEM fluorescent thermal labels, delivering quality, reliability, and excellence every step of the way.

Methods To OEM Fluorescent Thermal Labels Manufacturer Industry Giant Factory

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Direct Printing | Printing directly onto labels using thermal transfer technology. | High quality, quick turnaround, reduced waste. | Initial setup costs can be high. |

| Roll-to-Roll Printing | Utilizes continuous rolls of label material for large production runs. | Cost-effective for large quantities, consistent quality. | Less flexibility for small runs or custom jobs. |

| Digital Printing | Uses digital files to print labels without the need for plates. | Ideal for short runs, quick changes in design. | Higher cost per unit in comparison to offset printing. |

| Flexographic Printing | A rotary printing process using flexible relief plates. | Great for high volume and multi-color printing. | Long setup times, less effective for small batches. |

| Thermal Transfer Printing | Involves heat transferring ink from a ribbon onto a label. | Durable prints, water and abrasion-resistant labels. | Requires replacement of ribbons, which can increase costs. |

Practical Methods To OEM Fluorescent Thermal Labels Manufacturer Exceeds Industry Benchmarks Factory

B

Ben Lewis

Quality was better than I imagined! The after-sales service was responsive and extremely professional.

06

June

2025

O

Oliver Young

Truly exceptional product! The staff is knowledgeable and their support service is top-tier.

05

July

2025

B

Bella Murphy

I’m impressed by the quality! The support team handled my questions like true professionals.

11

June

2025

H

Henry Williams

Top-notch quality! I appreciate how professional and prompt their service team has been.

03

June

2025

E

Eli Carter

This product is remarkable! The support team provided excellent guidance and assistance.

28

May

2025

A

Avery Morgan

The product quality is fantastic! Their customer service agents were very responsive and helpful.

10

June

2025

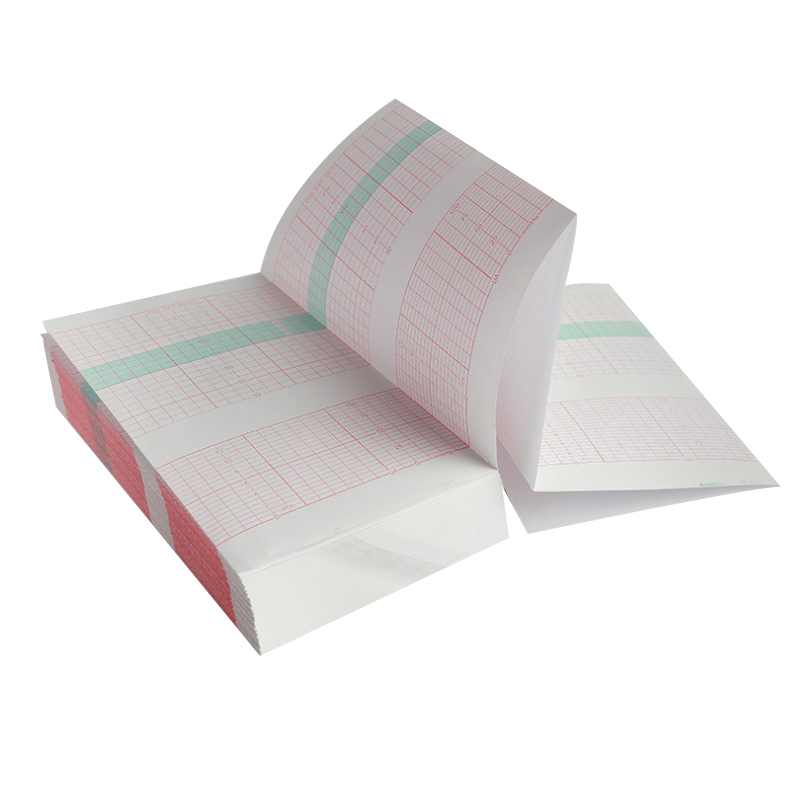

Thermal labels

Thermal labels