OEM Label Material Specifications: CE Certification & Top Exporter Company

Looking for high-quality OEM label material specifications? Our offerings at ShenZhen Sailing Paper Co., Ltd. are tailored to meet the diverse needs of manufacturers and suppliers alike. We understand that every project demands precision, and our range of label materials is designed to perform under various conditions. Whether you require synthetic substrates for durability or paper-based options for eco-friendliness, we got you covered, As an experienced partner in the industry, I know the importance of compliance and reliability in OEM products. That’s why our materials undergo rigorous testing to ensure they meet international standards. Our commitment to quality means you can trust us to deliver materials that enhance your brand's identity and meet your specific requirements. Let's collaborate to find the perfect label solutions for your projects and boost your business efficiency!

How To Source OEM Label Material Specifications Industry Leaders Market Leader

In the ever-evolving landscape of manufacturing and supply chain management, sourcing OEM label material specifications has become crucial for market leaders aiming to maintain a competitive edge. At Sailing, we understand that since our inception in 2011, the ability to provide high-quality, tailored solutions is what sets us apart as a trusted partner in the printing, packaging, and logistics consumables industry. Our dual manufacturing presence in China and Malaysia enables us to cater to diverse market needs, ensuring that global buyers can access premium materials that meet rigorous industry standards.

By collaborating closely with our clients, we develop OEM label materials that adhere to specific technical specifications and regulatory requirements. This tailored approach not only enhances product functionality but also strengthens brand identity across various sectors. As industry leaders, we leverage advanced technologies and insights to innovate and optimize our product offerings, ensuring they align with market trends and customer expectations. When looking to source label materials, partnering with a reputable manufacturer like Sailing can lead to increased efficiency and long-term success for your business. Embrace the opportunity to elevate your product line by choosing a partner dedicated to excellence and innovation.

How To Source OEM Label Material Specifications Industry Leaders Market Leader

| Material Type | Specification | Common Applications | Supplier Region | Lead Time (Days) |

|---|---|---|---|---|

| Polyester Film | 0.5 mil thickness, Gloss Finish | Product Labels, Tags | North America | 15 |

| Vinyl | 3 mil thickness, Matte Finish | Indoor/Outdoor Signage | Europe | 10 |

| Paper | 60 GSM, Semi-Gloss | General Purpose Labels | Asia | 20 |

| Polypropylene | 1 mil thickness, Clear Finish | Beverage Labels, Cosmetic Labels | South America | 12 |

| Thermal Transfer | 80 GSM, White | Shipping Labels, Barcode Labels | Australia | 8 |

10 Essential Tips For OEM Label Material Specifications Pioneers in the Field Manufacturer

D

David Wilson

High-quality materials and excellent performance. The customer support team was highly professional and responsive.

08

June

2025

G

Grace Nelson

Wonderful quality! Their dedicated support team resolved all my queries without hesitation.

22

June

2025

J

Jameson Harris

Great value for the quality! The service team was highly skilled and attentive to my needs.

10

June

2025

A

Ava Green

Quality and service both exceeded my expectations! The team was highly responsive and informative.

07

May

2025

E

Ella Williams

I’m impressed! The product quality and after-sales support crew were both top-notch.

11

June

2025

L

Liam Thomas

Really top-quality product! The after-sales service was quick and very professional.

29

May

2025

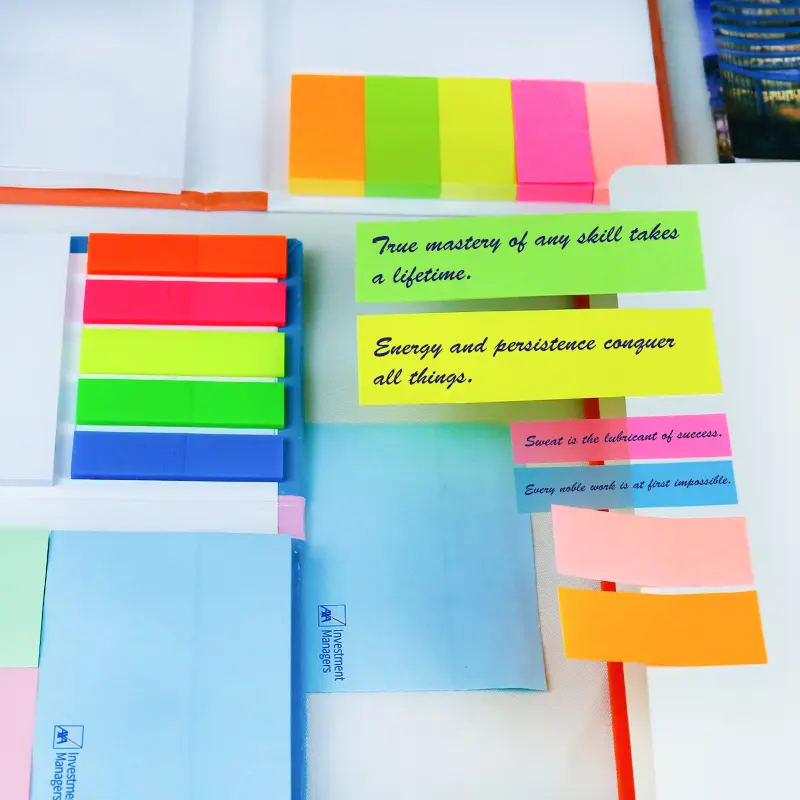

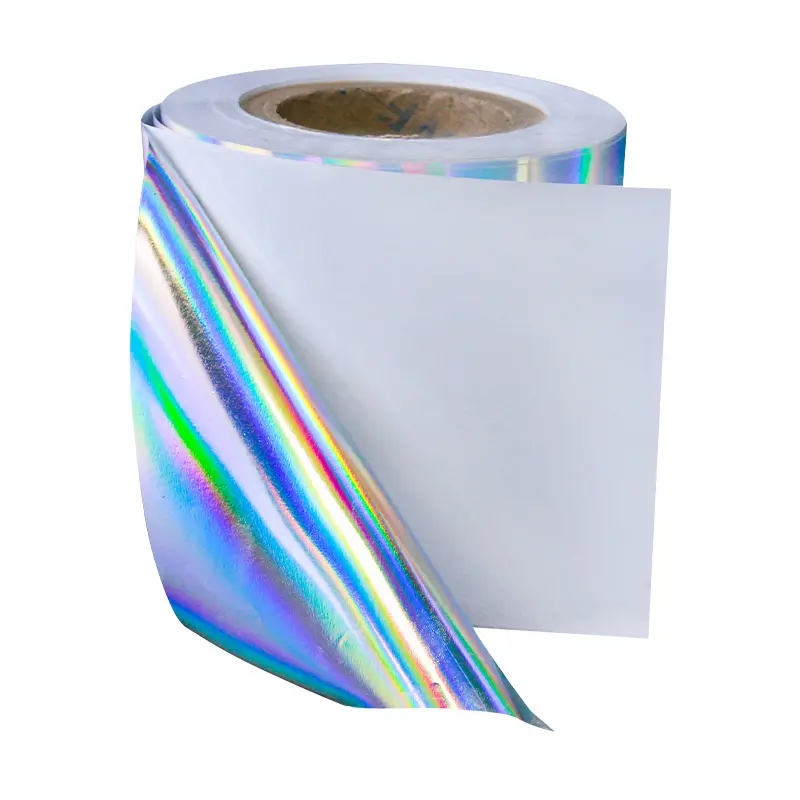

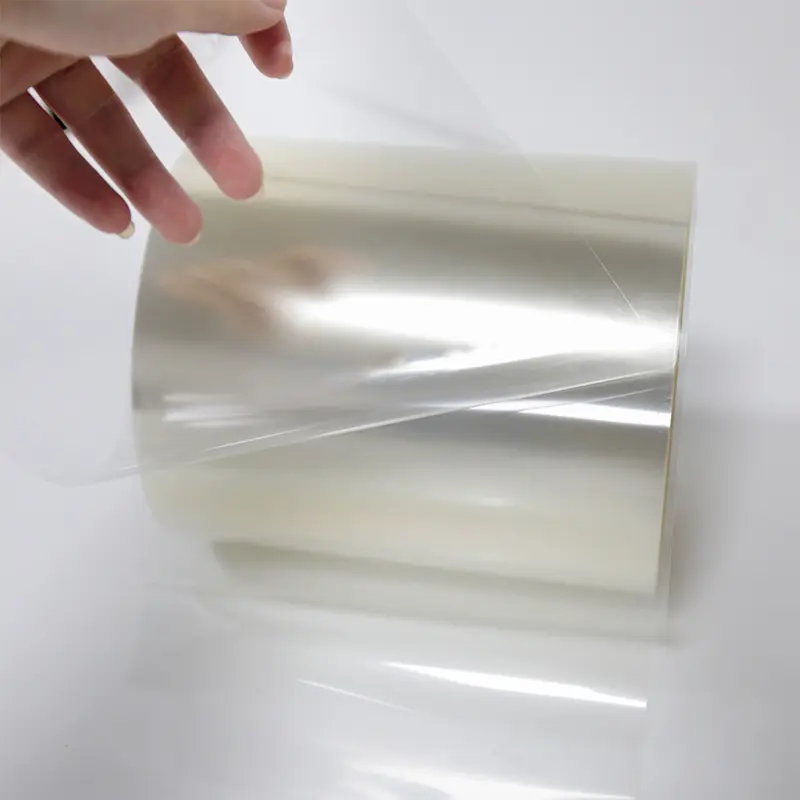

Thermal labels

Thermal labels