Top PE Film Label Companies & Products for Exceptional Packaging Solutions

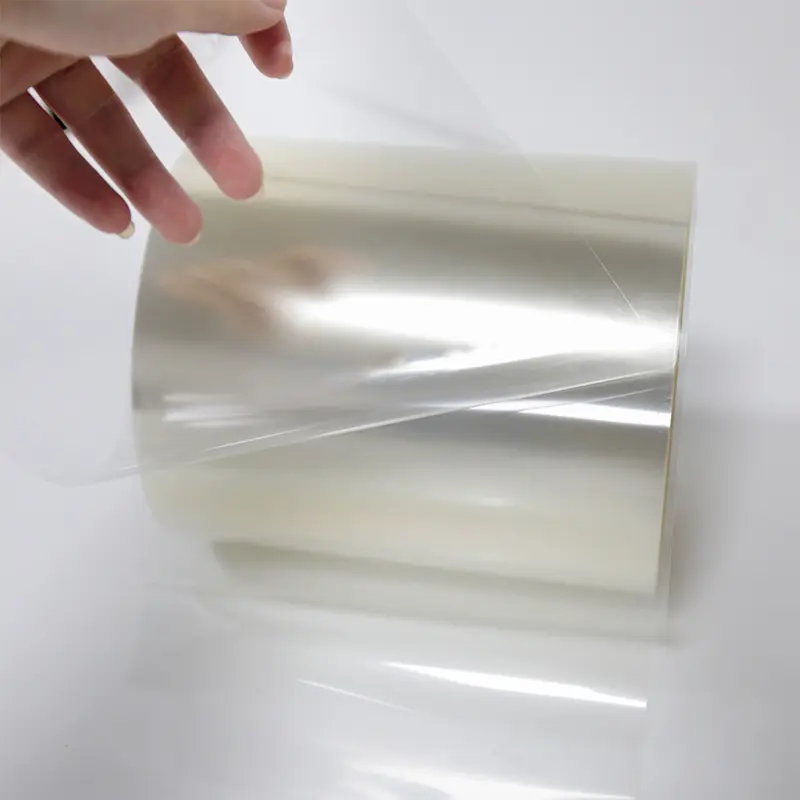

Our high-quality PE film labels are designed to elevate your products and meet your unique requirements. We offer tailored ODM solutions that cater to various applications while maintaining competitive pricing that aligns with your budget. With our extensive experience as an exporter, we ensure smooth international transactions and timely delivery of your labels. Known for their durability and excellent adhesion, our PE film labels are crafted with meticulous attention to detail, guaranteeing both aesthetic appeal and superior performance in diverse conditions. For the best options to boost your product visibility, please check our latest pricelist or contact us for samples and specific requests.Proven Methods To pe film label Factory Trusted by Pros

In today's competitive marketplace, finding a reliable and efficient partner for your printing and packaging needs is crucial. At Sailing, we understand the challenges global buyers face when sourcing high-quality PE film labels. Established in 2011, Sailing has transformed from a local paper converter into an internationally recognized group, with state-of-the-art production facilities in both China and Malaysia. Our commitment to excellence has made us a trusted choice for professionals across various industries.

What sets Sailing apart is our dedication to implementing proven methods in both production and quality assurance. Our extensive experience in the printing, packaging, and logistics consumables sectors has equipped us with the skills to meet diverse customer needs. We prioritize the use of advanced technology and sustainable practices in our manufacturing processes, ensuring that our PE film labels not only meet but exceed industry standards. Additionally, our global logistics capabilities guarantee timely delivery and efficient service, making the procurement process seamless for our international partners.

As businesses continue to evolve, the demand for high-quality, reliable labeling solutions is more critical than ever. By choosing Sailing as your PE film label supplier, you’re partnering with a factory trusted by professionals. Our focus on innovation, quality, and customer satisfaction positions us to support your business goals and provide effective solutions that enhance your brand's identity. Join us in creating a world of possibilities with exceptional labeling solutions designed for the modern marketplace.

Proven Methods To PE Film Label Factory Trusted by Pros

| Method | Description | Advantages | Limitations |

|---|---|---|---|

| Digital Printing | Uses digital technology to print labels on demand. | High customization and faster turnaround time. | Higher per-unit cost for small runs. |

| Flexographic Printing | A relief printing process using flexible plates. | Cost-effective for large runs with vibrant colors. | More setup time and cost for small jobs. |

| Screen Printing | Ink is pushed through a mesh screen onto the substrate. | Durable and suitable for textured surfaces. | Less efficient for complex images and gradients. |

| Thermal Transfer | Uses heat to transfer ink from a ribbon onto labels. | High-quality, durable prints for barcodes and text. | Limited color options compared to other methods. |

| Lamination | A protective layer applied over the label. | Increased durability and resistance to moisture. | Adds to the overall cost and production time. |

How To pe film label From Concept to Delivery Industry Leaders

E

Emma Johnson

Excellent craftsmanship! I truly appreciate the prompt and professional service from the support team.

14

June

2025

S

Sofia Mitchell

Absolutely wonderful quality! Their team demonstrated unparalleled professionalism throughout.

01

July

2025

E

Ella White

Exceptional quality! Their support team after purchase was very friendly and knowledgeable.

05

July

2025

A

Ava Green

Quality and service both exceeded my expectations! The team was highly responsive and informative.

07

May

2025

N

Natalie Torres

Incredible quality! Their support staff was prompt and skilled in addressing my questions.

01

June

2025

M

Michael Carter

Remarkable experience! The quality is superior, and their service team is incredibly professional.

24

June

2025

Thermal labels

Thermal labels