Top Polyimide Label Materials: Leading Products & Manufacturers You Need to Know

Our polyimide label material stands out for its ability to endure extreme temperatures and harsh environments, making it ideal for technical applications. These labels offer reliable adhesion to various surfaces, ensuring durability and performance in demanding conditions. Their versatility makes them suitable for industries such as aerospace, automotive, and electronics, where exceptional electrical insulation properties are essential. Whether for component labeling, identification, or safety purposes, our polyimide labels meet diverse needs with ease. Partnering with a trusted supplier like ShenZhen Sailing Paper Co., Ltd. ensures quality, reliability, and a consistent supply of innovative solutions tailored to your specifications. Choose our polyimide label material for superior performance and elevate your labeling projects.Must-Know Tips For Polyimide Label Material More Than a Supplier - A Partner Guarantees Peak Performance

In today’s global marketplace, choosing the right label material can significantly impact your product’s success. Polyimide labels, known for their high thermal stability and excellent chemical resistance, are essential in various industries, from electronics to aerospace. At Sailing, we have established ourselves not merely as a supplier but as a true partner to our clients. Since our inception in 2011, we've evolved from a local paper converter into a respected international group, operating production facilities in both China and Malaysia. This growth is a testament to our commitment to quality and partnership.

When selecting a polyimide label material, it's crucial to consider not only the specifications but the reliability of your supplier. Sailing’s extensive industry experience allows us to provide tailored solutions, ensuring that your label materials meet your specific needs. Our expertise in printing, packaging, and logistics consumables means we can aid in optimizing your operations while guaranteeing peak performance for your products. By collaborating closely with you, we can address challenges and innovate together, delivering superior results that elevate your brand in a competitive landscape.

Trust Sailing as your partner in navigating the complexities of label materials. By leveraging our global network and manufacturing capabilities, you can rest assured that your polyimide label solutions will excel in performance and durability. Let us work together to achieve excellence and drive your business forward.

Must-Know Tips For Polyimide Label Material More Than a Supplier - A Partner Guarantees Peak Performance

| Tip | Description | Benefit | Applications |

|---|---|---|---|

| Choose the Right Adhesive | Select adhesives that are compatible with polyimide to ensure durability. | Enhances adhesion and longevity of labels. | Electronics, Aerospace |

| Understand Temperature Resistance | Polyimide labels can withstand high temperatures, ideal for thermal environments. | Prevents label degradation in extreme conditions. | Automotive, Manufacturing |

| Evaluate Chemical Resistance | Check the labels' resistance to various chemicals to avoid deterioration. | Ensures labels remain intact in harsh environments. | Laboratories, Electronics |

| Focus on Printability | Ensure printing methods are suitable for polyimide material. | Achieves high-quality, legible labels. | Electronics, Medical Devices |

| Work with a Trusted Partner | Collaborate with suppliers who provide comprehensive support and guidance. | Maximizes the label performance through shared expertise. | All industries requiring durable labeling solutions. |

Methods To choose Polyimide Label Material Manufacturers You Can Rely On Dominates

H

Harper King

Great quality and performance! The team was professional, making the whole process seamless.

30

June

2025

B

Ben Lewis

Quality was better than I imagined! The after-sales service was responsive and extremely professional.

06

June

2025

L

Layla Martinez

Exceptional product quality! Their support staff was warm and very professional in their approach.

04

June

2025

W

Wyatt Anderson

Impressive quality! The dedication shown by the customer support team was commendable.

06

June

2025

L

Lily Torres

Superb quality! Customer support was prompt and professional, making the buying process easy.

31

May

2025

Z

Zoe Gonzalez

Absolutely outstanding! The quality of the product and the service were both exemplary.

16

May

2025

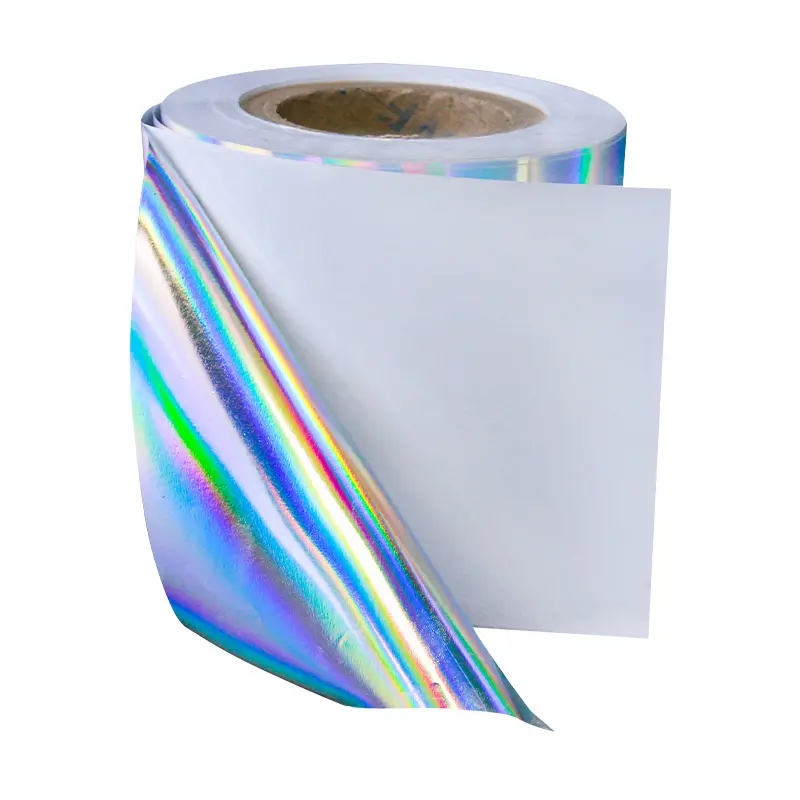

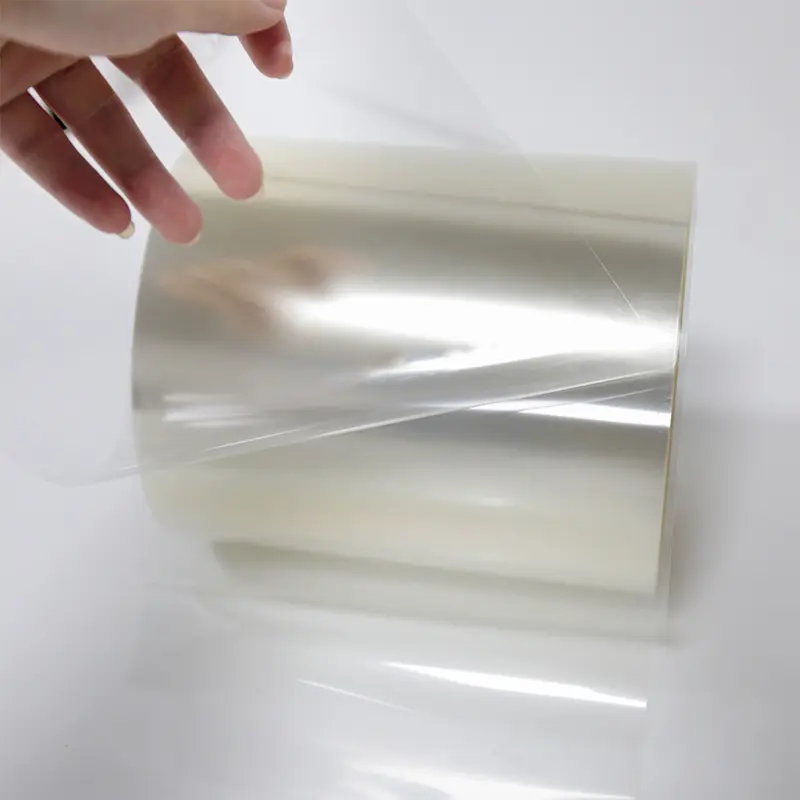

Thermal labels

Thermal labels