High-Quality OEM Rewinding & Slitting Machines for All Industrial Applications

Our Rewinding and Slitting Machine exemplifies efficiency and quality in the paper industry. Engineered with precision, it ensures high-quality output for smooth and effective production. As a leading exporter, we prioritize reliability and performance, crafting machinery that adheres to the highest standards. We provide competitive quotes tailored to fit your operational needs, making it easier to enhance your production processes. Whether scaling up or optimizing existing workflows, our machines from ShenZhen Sailing Paper Co., Ltd. will elevate your productivity. Contact us today to learn more and see how we can support your paper production goals!

Expert Choice of Rewinding And Slitting Machine Factory From Concept to Delivery Manufacturer

As a leading manufacturer established in 2011, Sailing has transformed from a local paper converter into a robust international group, with production facilities strategically located in China and Malaysia. Our commitment to excellence in the production and export of printing, packaging, and logistic consumables positions us as a trusted partner for businesses seeking high-quality, innovative solutions. One of our standout offerings, the rewinding and slitting machine, epitomizes our expertise in delivering efficient and reliable manufacturing equipment tailored to meet diverse consumer needs.

Our rewinding and slitting machines are engineered for exceptional performance and versatility, catering to various applications in the printing and packaging industry. With a focus on maximizing productivity and minimizing waste, our machines ensure precision in every roll and slit. From the initial concept to the final delivery, our dedicated team of experts works closely with clients, providing tailored solutions that align with their specific operational requirements. By leveraging advanced technology and industry best practices, we have built a reputation for delivering high-quality machinery that enhances operational efficiency and drives business growth.

At Sailing, we understand that global procurement requires not just quality products, but also a dependable partnership. As we continue to expand our international footprint, we invite global buyers to connect with us for their rewinding and slitting machine needs. Experience firsthand our commitment to quality, innovation, and customer satisfaction as we partner with you to navigate the evolving landscape of the printing and packaging industry. Let Sailing be your expert choice for all your machinery requirements, from concept to delivery.

Expert Choice of Rewinding And Slitting Machine Factory From Concept to Delivery Manufacturer

| Dimension | Specification | Material | Usage | Lead Time |

|---|---|---|---|---|

| 1000mm x 400m | High-speed | BOPP Film | Food Packaging | 6 weeks |

| 1200mm x 500m | Automatic | PET Film | Electrical Insulation | 8 weeks |

| 1500mm x 300m | Semi-automatic | Paper | Label Printing | 5 weeks |

| 800mm x 600m | Manual | Aluminum Foil | Cooking & Baking | 4 weeks |

| 1000mm x 250m | High-Precision | PVC Film | Medical Packaging | 7 weeks |

How To Decide Between Rewinding And Slitting Machine Factory Your Trusted OEM Partner Global Reach

L

Lucas Allen

Superior product quality! The customer service representatives were incredibly helpful and informative.

25

May

2025

W

Wyatt Anderson

Impressive quality! The dedication shown by the customer support team was commendable.

06

June

2025

N

Noah Lewis

Awesome product quality! The support team offered thorough and professional assistance.

11

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

A

Avery Morgan

The product quality is fantastic! Their customer service agents were very responsive and helpful.

10

June

2025

N

Natalie Torres

Incredible quality! Their support staff was prompt and skilled in addressing my questions.

01

June

2025

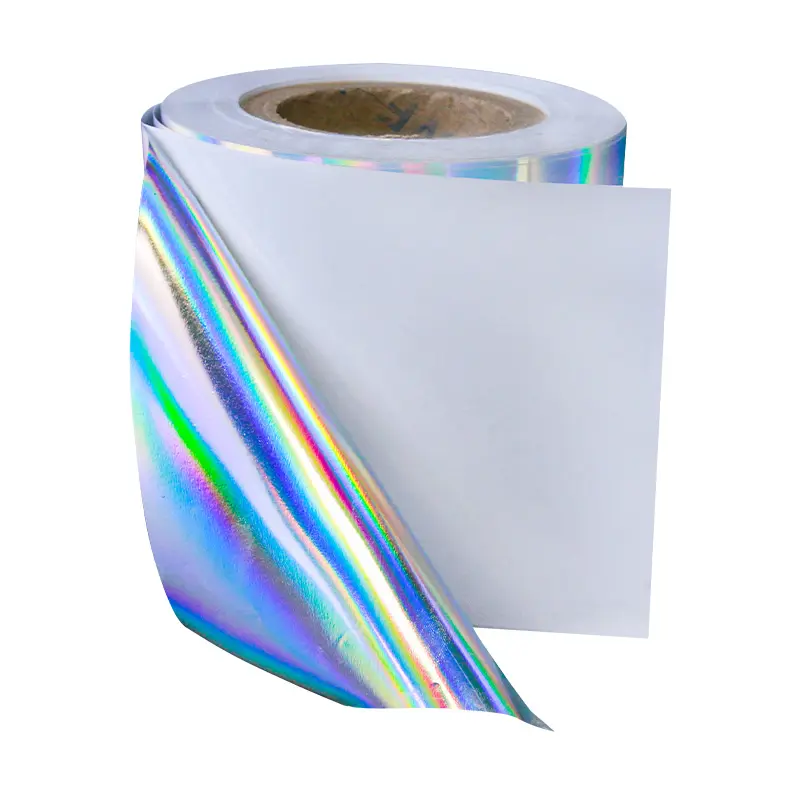

Thermal labels

Thermal labels