Affordable Slitting Label Material from China Factories – Request Your Pricelist Now!

Are you in need of premium slitting label material? With extensive industry experience, we understand the demands of manufacturers and businesses requiring durable and reliable label solutions. Our slitting label materials are engineered to meet the stringent requirements of various applications, helping your products make a lasting impression. As a dedicated supplier, we proudly offer customized solutions tailored to your unique needs. Our unwavering commitment to quality ensures you receive consistent performance and outstanding results. Whether you're a large manufacturer or a small enterprise, we are here to assist you at every stage of your journey.Insider Tips For Slitting Label Material in 2025 Sets the Industry Standard

As we step into 2025, the demand for efficient and high-quality slitting label materials continues to rise in the packaging industry. At Sailing, we have evolved from a local paper converter to a prominent international player, leveraging our production bases in China and Malaysia to meet diverse global needs. Our deep-rooted expertise in printing, packaging, and logistic consumables uniquely positions us to offer insights that can set industry standards.

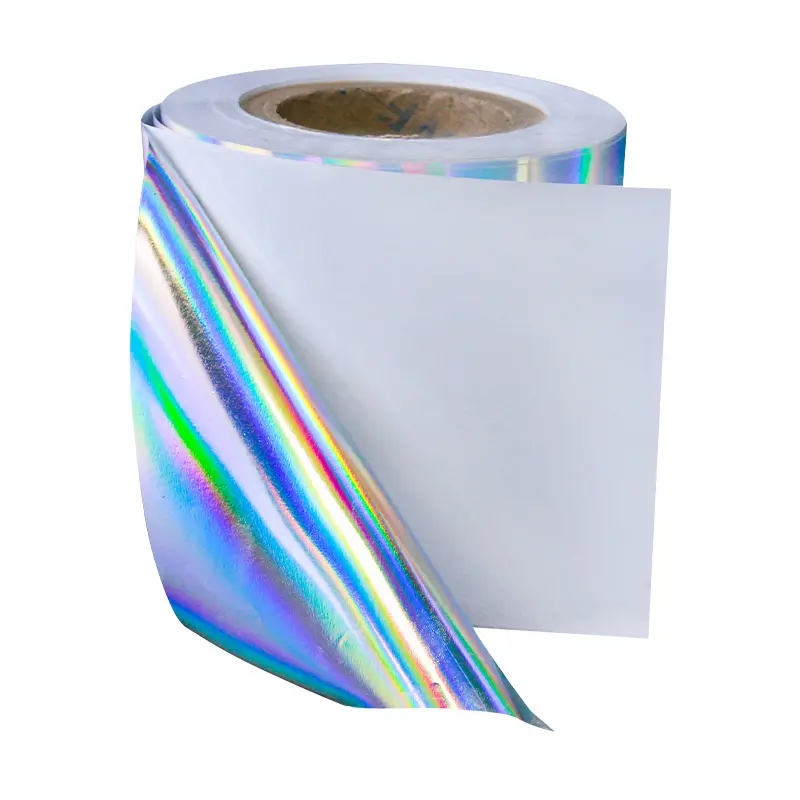

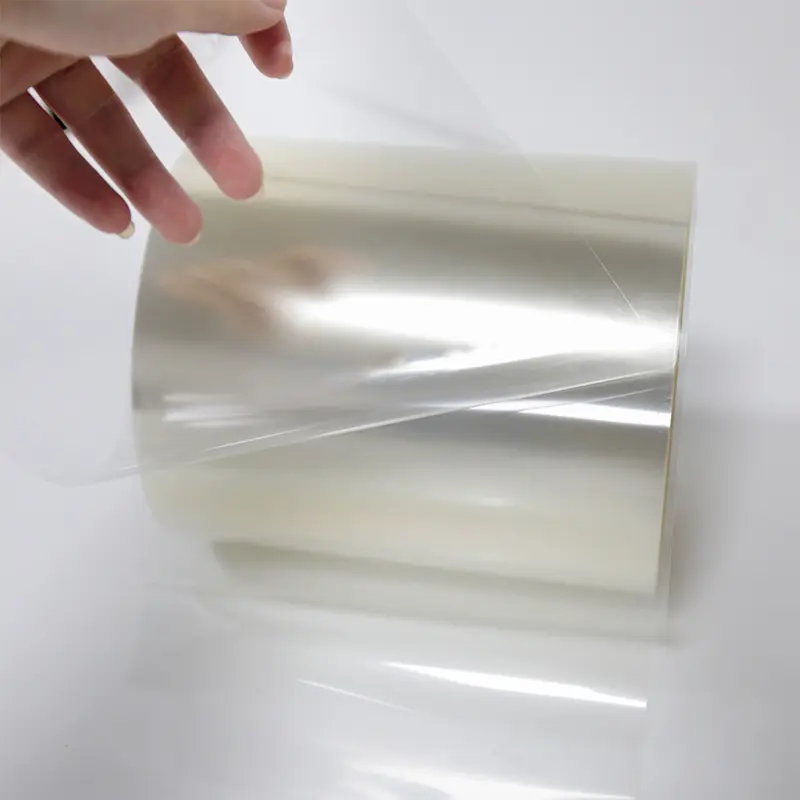

One insider tip for slitting label material involves understanding the nuances of substrate selection. Choosing the right substrate not only enhances the durability of labels but also significantly impacts the slitting process's efficiency. Our state-of-the-art technology allows for the precise cutting of various materials, ensuring consistency and quality with every batch. Additionally, collaborating with reliable suppliers who prioritize sustainability can streamline your procurement process while aligning with global environmental standards.

Moreover, embracing innovative techniques such as digital printing and automation can revolutionize your label production landscape. In today's fast-paced market, adapting to these advancements ensures a competitive edge. At Sailing, we are committed to driving innovation and efficiency in every aspect of our operations, releasing the potential for our clients to captivate their markets. By adopting these tips, global buyers can navigate the evolving landscape of label materials with confidence and foresight.

Insider Tips For Slitting Label Material in 2025 Sets the Industry Standard

| Tip | Description | Benefit | Expected Outcome |

|---|---|---|---|

| Use High-Quality Blades | Invest in premium slitting blades that deliver precise cuts. | Improved cut quality and reduced downtime. | Higher customer satisfaction and less waste. |

| Optimize Machine Settings | Regularly calibrate slitting machines for optimal performance. | Enhanced efficiency and consistency. | Increased throughput and lower operational costs. |

| Train Your Staff | Provide regular training for operators on best practices. | Reduce errors and improve safety. | Higher productivity and lower risk of accidents. |

| Maintain Equipment Regularly | Schedule regular maintenance checks for all machinery. | Extend the lifespan of equipment. | Reduced capital expenditure on new machinery. |

| Invest in Software Solutions | Use advanced software for tracking and managing workflow. | Increased oversight and efficiency. | Better decision-making and resource allocation. |

How To Pick The Right Slitting Label Material Ahead of the Curve Service Backed by Expertise

J

Jacob Gonzalez

This product delivers on quality! The after-sales support was knowledgeable and efficient.

25

May

2025

B

Ben Lewis

Quality was better than I imagined! The after-sales service was responsive and extremely professional.

06

June

2025

C

Chloe Hill

Highly satisfied with my order! The after-sales service was professional and prompt.

19

June

2025

I

Isaac Phillips

Fantastic quality! The customer service was attentive and very knowledgeable.

31

May

2025

B

Bella Murphy

I’m impressed by the quality! The support team handled my questions like true professionals.

11

June

2025

L

Lucy Thompson

I am extremely satisfied! The service staff displayed remarkable professionalism and skill.

02

July

2025

Thermal labels

Thermal labels