Expert Maintenance for Wholesale Slitting Machines | Leading Manufacturer Services

Maintaining your slitting machines is essential for optimal performance and longevity. As an OEM, Exporter, and Manufacturer, I offer a thorough maintenance solution tailored to your equipment needs. With my deep expertise from working with ShenZhen Sailing Paper Co., Ltd., I am well-equipped to address common challenges and improve machine efficiency. Regular maintenance reduces downtime, maximizes production capabilities, and ultimately extends the lifespan of your machinery. I provide both routine inspections and specialized repairs, ensuring your operations run seamlessly. Partnering with me guarantees a commitment to quality service designed around your unique requirements, enabling your business to thrive.

How To Pick The Right Slitting Machine Equipment Maintenance Factory-Direct Excellence Stands Out

When it comes to selecting the right slitting machine equipment maintenance provider, excellence is key. Since our establishment in 2011, Sailing has transformed from a local paper converter into a globally recognized group company, with production facilities in both China and Malaysia. Our commitment to quality in printing, packaging, and logistic consumables sets us apart from the competition, making us an ideal partner for businesses looking to optimize their maintenance operations.

Choosing a factory-direct maintenance service ensures you have direct access to specialized expertise and equipment tailored to your specific needs. At Sailing, we pride ourselves on our streamlined processes and dedicated support, helping you minimize downtime and maximize productivity. Our international experience allows us to understand the unique challenges faced by global buyers, and our responsive customer service guarantees prompt solutions.

In a fast-paced market, the reliability of your slitting machine can drastically impact your operation. By partnering with a factory-direct provider like Sailing, you’re not just investing in maintenance; you’re ensuring sustained excellence and competitive advantage for your business. Let us help you elevate your operations through unmatched quality and dedicated service!

How To Pick The Right Slitting Machine Equipment Maintenance Factory-Direct Excellence Stands Out

| Feature | Description | Importance Level | Maintenance Frequency |

|---|---|---|---|

| Technical Support | Availability of knowledgeable technicians for troubleshooting and maintenance advice. | High | As needed |

| Parts Availability | Quick access to spare parts and components for repairs and replacements. | Medium | Monthly check |

| Training Services | Provision of training sessions for operators to handle equipment effectively. | High | Bi-annually |

| Customer Reviews | Feedback from other clients regarding service quality and machine reliability. | High | N/A |

| Warranty Terms | Clear warranty conditions and duration offered on machines and components. | Medium | N/A |

| Service Contracts | Options for extended service contracts to ensure ongoing maintenance support. | Medium | Yearly |

Curated Selection of Slitting Machine Equipment Maintenance Supplies the World’s Top Brands Sets the Industry Standard

H

Harper King

Great quality and performance! The team was professional, making the whole process seamless.

30

June

2025

Z

Zoe Mitchell

I love this product! The support team showed great understanding and professionalism throughout.

24

June

2025

C

Chloe Hill

Highly satisfied with my order! The after-sales service was professional and prompt.

19

June

2025

H

Henry Williams

Top-notch quality! I appreciate how professional and prompt their service team has been.

03

June

2025

M

Michael Carter

Remarkable experience! The quality is superior, and their service team is incredibly professional.

24

June

2025

J

Jackson Wilson

Superior quality! The support team was very helpful and knowledgeable throughout the process.

05

July

2025

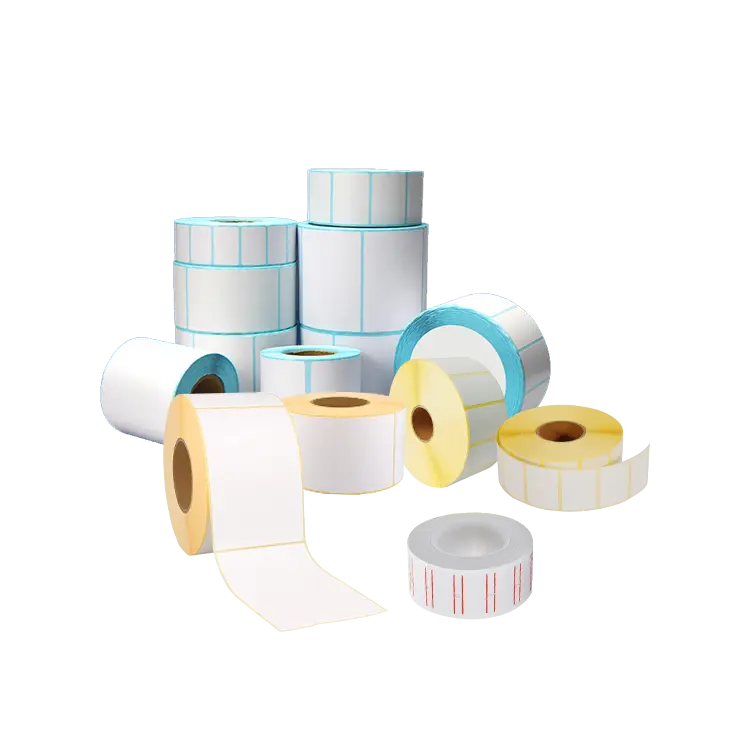

Thermal labels

Thermal labels