Cheap Thermal Transfer vs Direct Thermal Labels: A Guide to Top Manufacturers

Selecting the right labeling solution is crucial for any business. Thermal transfer labels are ideal for situations requiring durability and longevity, while direct thermal labels provide an economical choice for short-term applications. Each type serves specific needs effectively. At ShenZhen Sailing Paper Co., Ltd., we support a broad range of businesses, from manufacturers to ODM providers. Our extensive pricelist ensures affordably tailored options without compromising quality. Committed to delivering high-caliber products that meet your expectations, we are here to provide the optimal labeling solutions for your business requirements.

Reasons to Choose Thermal Transfer Labels Vs Direct Thermal Labels Suppliers Guarantees Peak Performance Supplier

When it comes to choosing the right labels for your business needs, understanding the differences between thermal transfer labels and direct thermal labels is crucial. Thermal transfer labels are known for their durability and longevity, making them ideal for applications where the label must withstand various environmental factors. They utilize a ribbon to transfer ink onto the label, resulting in high-quality images and text that resist fading over time. This characteristic is especially beneficial for industries that require long-lasting labels, such as logistics, retail, and manufacturing.

On the other hand, direct thermal labels are designed for short-term use, as they rely on heat-sensitive materials that can fade when exposed to light or heat. While they are a cost-effective choice for temporary labeling needs, they may not be suitable for products that require extended shelf life or exposure to harsh conditions. At Sailing, we specialize in both types of labels, offering a comprehensive selection tailored to meet varied business requirements. Established in 2011, we have evolved into a global leader in printing, packaging, and logistic consumables, with production facilities in China and Malaysia. Our commitment to quality ensures that our clients receive the best products that guarantee peak performance, allowing them to enhance their operational efficiency while reducing costs.

Choosing the right label is not just about cost; it is about finding a reliable supplier that understands your needs and can deliver exceptional quality. With Sailing, global purchasers can rely on our expertise and extensive range of products to find the perfect labeling solution, whether for shipping, inventory management, or product branding. Our strategic focus on innovation and quality makes us a partner of choice for businesses looking to optimize their labeling processes and maintain a competitive edge in their respective markets.

Reasons to Choose Thermal Transfer Labels Vs Direct Thermal Labels

| Feature | Thermal Transfer Labels | Direct Thermal Labels |

|---|---|---|

| Durability | High (Resistant to heat, moisture, and fading) | Medium (Sensitive to heat and light) |

| Print Quality | Excellent (High resolution and clarity) | Good (Sufficient for standard applications) |

| Cost | Generally higher (Requires ribbons) | Generally lower (No ribbons needed) |

| Applications | Best for long-term labeling (e.g., product labels, outdoor use) | Best for short-term labeling (e.g., shipping labels, receipts) |

| Speed of Printing | Moderate (Slower due to ribbon feed) | Fast (No ribbon change required) |

| Environmental Considerations | Can be made with eco-friendly materials | Options are available but often less eco-friendly |

Key Steps to Choosing Thermal Transfer Labels Vs Direct Thermal Labels Suppliers Factory Pioneers in the Field

D

David Wilson

High-quality materials and excellent performance. The customer support team was highly professional and responsive.

08

June

2025

A

Ava Anderson

Top-notch quality! The representatives were attentive and addressed my concerns promptly.

03

June

2025

V

Victoria Wright

The quality of this product is fantastic! I appreciated the professionalism of the team.

01

July

2025

B

Bella Murphy

I’m impressed by the quality! The support team handled my questions like true professionals.

11

June

2025

C

Camila Long

I adore this product! The support staff was incredibly knowledgeable and responsive.

22

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

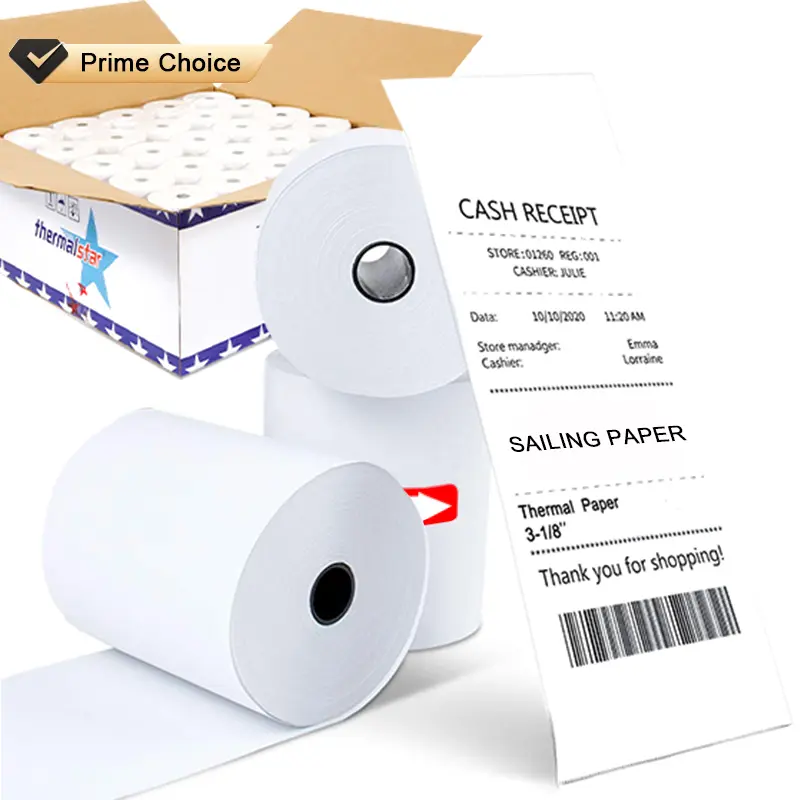

Thermal labels

Thermal labels