Comparing Thermal Transfer and Laser Label Durability: Top Rated Products Reviewed

Understanding the differences between thermal transfer and laser labels is essential for label durability. Based on my experience, thermal transfer labels exhibit exceptional resilience, making them ideal for long-term use. Their resistance to fading and scratching often makes them the preferred choice for companies prioritizing quality. As an exporter dedicated to sourcing high-quality products, I recognize the significance of CE certification for compliance and safety. ShenZhen Sailing Paper Co., Ltd. is a trusted supplier that meets stringent industry standards. Choosing the right label material can significantly impact your operations, so it's important to consider what best suits your needs.

Decoding Thermal Transfer Vs Laser Label Durability Delivers Unmatched Quality Ahead of the Curve

In the fast-paced world of global commerce, the importance of label durability cannot be overstated. At Sailing, we understand that the choice between thermal transfer and laser labels plays a significant role in ensuring your products meet the highest quality standards. Since our establishment in 2011, we have evolved from a local paper converter into an esteemed international group with manufacturing operations in both China and Malaysia, dedicated to delivering top-notch printing, packaging, and logistic solutions.

Thermal transfer labels offer remarkable durability, making them ideal for environments that demand resilience against harsh conditions. The technology employs heat to transfer ink from a ribbon onto the label surface, resulting in bold, long-lasting prints that resist smudging and fading. In contrast, laser labels provide precision and speed, ideal for high-volume applications. However, they may not always withstand the same level of wear and tear as thermal transfer counterparts. Understanding these distinctions enables global buyers to make informed decisions tailored to their specific needs, ensuring that the labels they choose withstand the test of time.

At Sailing, we prioritize quality and innovation, continuously refining our processes to stay ahead of the curve. Our extensive experience in the industry empowers us to offer products that not only meet but exceed international standards. Whether you’re looking for resilient thermal transfer labels or high-speed laser printing solutions, we are committed to providing unmatched quality that supports your business objectives. Partner with us to navigate the complexities of labeling, enhancing the value of your products in the global marketplace.

Decoding Thermal Transfer Vs Laser Label Durability Delivers Unmatched Quality Ahead of the Curve

| Label Type | Durability (Years) | Resistance to Water | Resistance to UV Light | Resistance to Chemicals | Typical Applications |

|---|---|---|---|---|---|

| Thermal Transfer | 5-7 | Yes | Yes | Moderate | Shipping, Retail |

| Laser Label | 8-10 | Yes | Excellent | High | Industrial, Chemical |

Why Trust Thermal Transfer Vs Laser Label Durability Your Trusted OEM Partner Sets the Industry Standard

J

James Thompson

The quality of this product exceeded my expectations. The team provided outstanding support throughout the purchasing process.

08

June

2025

B

Ben Lewis

Quality was better than I imagined! The after-sales service was responsive and extremely professional.

06

June

2025

V

Victoria Wright

The quality of this product is fantastic! I appreciated the professionalism of the team.

01

July

2025

G

Gabriel Martinez

Wonderful quality! The professionalism of their customer service was quite impressive.

18

June

2025

L

Lily Walker

Very happy with my purchase! The quality is excellent and customer service was great.

25

May

2025

J

Jackson Wright

I’m very impressed! The craftsmanship is excellent and customer service was very attentive.

13

May

2025

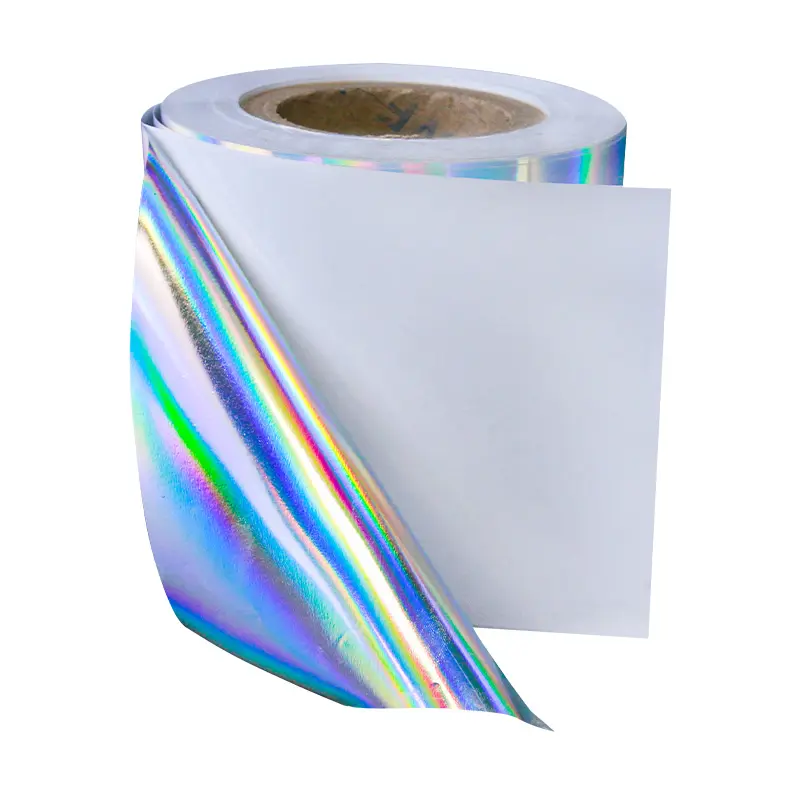

Thermal labels

Thermal labels