Premium Vertical Slitting Machines | Leading Supplier for High-Quality Solutions

A reliable Vertical Slitting Machine is essential for enhancing operational efficiency. With extensive experience as an ODM supplier, we cater to businesses seeking precise and efficient manufacturing solutions. Our Vertical Slitting Machines are engineered for consistent high-quality slitting across a range of materials. At ShenZhen Sailing Paper Co., Ltd., we focus on delivering customized solutions tailored to the specific needs of our clients. Equipped with advanced technology, our machines ensure durability and ease of operation. Whether you operate a small business or a large manufacturing facility, our competitive pricing and outstanding customer support position us as your ideal partner in boosting productivity and optimizing production processes.

Effective Ways To Vertical Slitting Machine Now Trending Winning in 2025

In recent years, the demand for vertical slitting machines has surged, particularly as industries strive for precision and efficiency in their manufacturing processes. As we look toward 2025, businesses are increasingly seeking reliable and innovative solutions to enhance their production capabilities. At Sailing, we have leveraged our extensive experience since our establishment in 2011 to position ourselves at the forefront of this evolving market. Our international operations, with production facilities in both China and Malaysia, enable us to cater to a diverse clientele, ensuring they receive top-quality equipment tailored to their specific needs.

Vertical slitting machines are crucial for accurately cutting materials such as paper, films, and flexible packaging. With the industry's focus shifting towards sustainability and reducing waste, these machines are designed for optimal performance, enabling manufacturers to maximize output while minimizing resource consumption. At Sailing, we are committed to integrating cutting-edge technology into our machines, offering features that enhance efficiency and reduce downtime, thus ensuring our clients stay competitive in a rapidly changing marketplace.

As global procurement trends evolve, the importance of selecting the right partner cannot be overstated. Sailing not only provides high-quality vertical slitting machines but also offers comprehensive support and expertise to guide clients through the procurement process. Our robust logistics capabilities ensure timely delivery and service, creating a seamless experience from order to operation. By choosing Sailing, you are not just investing in equipment; you are partnering with a reliable ally to help you achieve operational excellence and meet the demands of the market in 2025 and beyond.

Effective Ways To Vertical Slitting Machine Now Trending Winning in 2025

| Method | Description | Benefits | Trends |

|---|---|---|---|

| Laser Slitting | Utilizes laser technology for precision cutting. | High accuracy, reduces waste, low maintenance. | Increased automation and reduced operational costs. |

| Rotary Slitting | Employs rotating blades for fast and efficient cutting. | Higher speed, better for large volume production. | Growing demand in packaging industries. |

| Shear Slitting | Involves cutting through the material using shear force. | Suitable for thicker materials, versatile applications. | Emphasis on sustainability and eco-friendly practices. |

| Die Cutting | Uses a die to cut shapes from materials. | Precision and ability to create complex designs. | Rising interest in customizable products. |

10 Essential Tips For Vertical Slitting Machine Delivers Unmatched Quality in 2025

J

James Thompson

The quality of this product exceeded my expectations. The team provided outstanding support throughout the purchasing process.

08

June

2025

N

Noah Lewis

Awesome product quality! The support team offered thorough and professional assistance.

11

June

2025

M

Matthew Scott

This product is of excellent quality! Service was attentive, professional, and smooth.

06

May

2025

L

Lily Torres

Superb quality! Customer support was prompt and professional, making the buying process easy.

31

May

2025

Z

Zoe Gonzalez

Absolutely outstanding! The quality of the product and the service were both exemplary.

16

May

2025

S

Sophia Adams

Absolutely satisfied! The product quality matched my expectations, and the service was very personalized.

11

May

2025

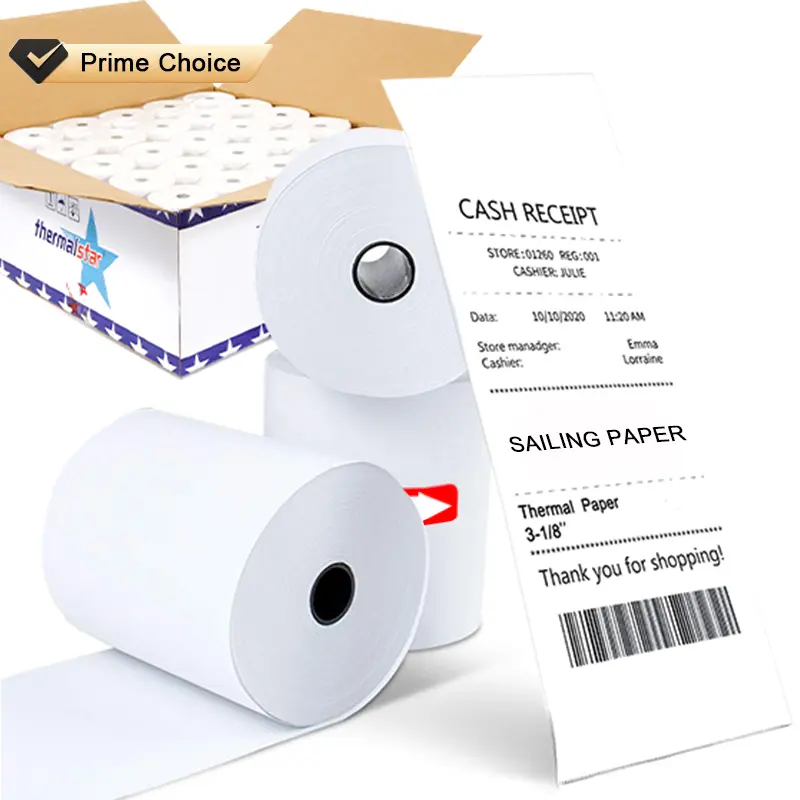

Thermal labels

Thermal labels