Wholesale Cleanroom Label Material: OEM Quotes for Top Quality Solutions

High-quality wholesale cleanroom label material is available here, specifically designed for cleanroom environments to meet the highest standards of cleanliness and reliability. Each label features CE certification, ensuring compliance with stringent industry requirements. Our diverse selection caters to various budgets, all while maintaining exceptional quality. Ideal for industries such as pharmaceuticals, electronics, and other critical sectors, our durable and high-performance materials keep your operations running smoothly. For inquiries about our product range or customizations, reach out to discuss the perfect cleanroom label solutions tailored to your business needs.In-Depth Analysis of Methods Wholesale Cleanroom Label Material Service Application

Cleanroom environments are critical across various industries, including pharmaceuticals, electronics, and biotechnology, where even the slightest contamination can lead to significant losses. Understanding the labeling requirements in such sterile settings is paramount for ensuring compliance and operational efficiency. This blog post delves into various methods of wholesale cleanroom label materials and their service applications, showcasing the pivotal role they play in maintaining the integrity of cleanroom operations.

Since our establishment in 2011, Sailing has evolved from a regional paper converter into a leading international group with manufacturing facilities in both China and Malaysia. Our extensive range of printing, packaging, and logistic consumables includes high-quality cleanroom labels designed specifically for controlled environments. These labels are produced using advanced materials that meet stringent cleanliness standards, ensuring they don’t contribute to particulate contamination. By focusing on custom solutions, we cater to the diverse requirements of global buyers, providing products that enhance traceability and streamline processes.

Furthermore, our commitment to innovation and quality enables us to stay ahead in the competitive landscape of cleanroom products. We not only supply labels but also offer tailored services to help our clients select the right materials and designs based on their specific applications. This in-depth analysis of cleanroom labeling methods is crucial for global purchasers looking for reliable partners who understand the complexities of their operational needs, solidifying Sailing’s reputation as a trusted supplier in the realm of cleanroom consumables.

In-Depth Analysis of Methods Wholesale Cleanroom Label Material Service Application

| Material Type | Adhesive Type | Temperature Resistance (°C) | Chemical Resistance | Application Area | Shelf Life (Years) | Cost per Unit ($) |

|---|---|---|---|---|---|---|

| Polypropylene | Permanent | -40 to 90 | Excellent | Medical Facilities | 3 | 0.05 |

| Polyester | Removable | -30 to 80 | Good | Pharmaceutical Labs | 4 | 0.08 |

| Vinyl | High Tack | -20 to 70 | Moderate | Cleanrooms | 5 | 0.10 |

| Paper | Standard | -10 to 60 | Poor | General Use | 2 | 0.03 |

How To Wholesale Cleanroom Label Material Custom Solutions, Is The Best

J

James Thompson

The quality of this product exceeded my expectations. The team provided outstanding support throughout the purchasing process.

08

June

2025

E

Emma Johnson

Excellent craftsmanship! I truly appreciate the prompt and professional service from the support team.

14

June

2025

L

Lucas Allen

Superior product quality! The customer service representatives were incredibly helpful and informative.

25

May

2025

L

Layla Martinez

Exceptional product quality! Their support staff was warm and very professional in their approach.

04

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

A

Avery Morgan

The product quality is fantastic! Their customer service agents were very responsive and helpful.

10

June

2025

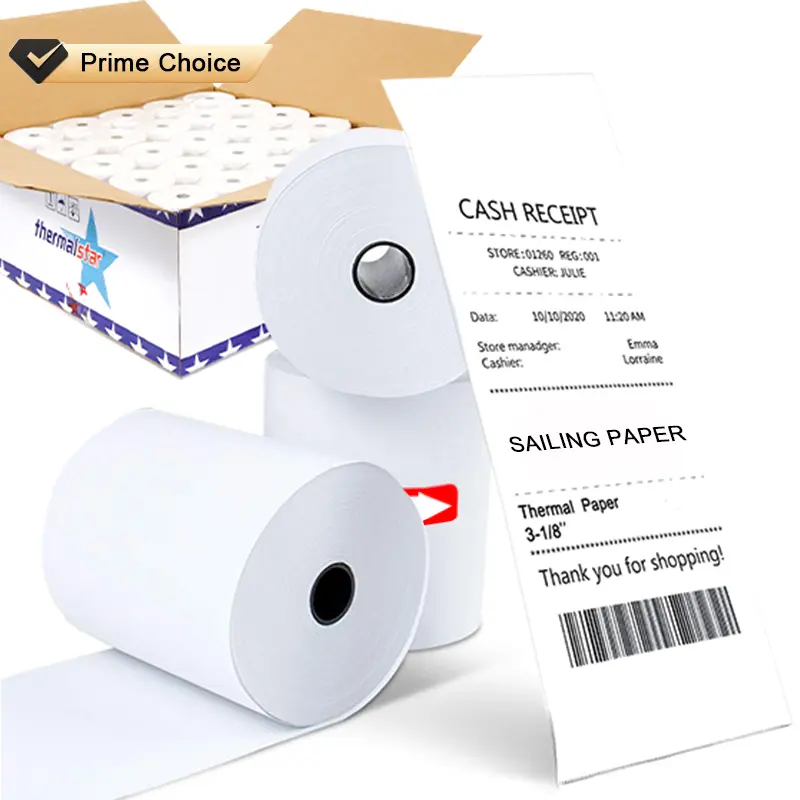

Thermal labels

Thermal labels