Wholesale Thermal Paper OEM Exporter: Pricelist & Manufacturing Process Guide

Understand the manufacturing process of high-quality thermal paper with our expert insights. Our factories are equipped with advanced technology and adhere to CE Certification standards, ensuring excellent print quality and durability in every roll. We use premium materials and enforce rigorous quality controls throughout production. By partnering with us, you not only gain superior thermal paper products but also establish a reliable relationship with a dedicated supplier. We're committed to supporting your business needs effectively. For wholesale options or any inquiries, please don't hesitate to contact us!

Proven Methods To Wholesale How Do They Make Thermal Paper Products Ahead of the Curve

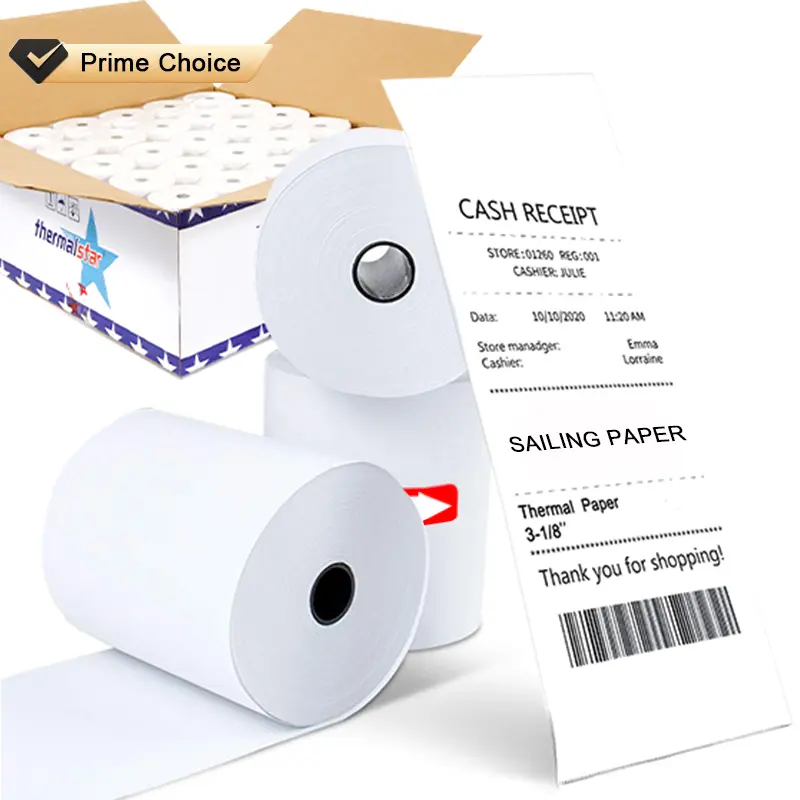

In the ever-evolving landscape of wholesale thermal paper products, staying ahead of the curve is essential for global buyers looking to maximize their supply chain efficiency. At Sailing, our journey since 2011 has transformed us from a local paper converter into an international powerhouse, with production bases in both China and Malaysia. This positional advantage allows us to cater to a diverse range of markets, ensuring timely delivery and competitive pricing for our thermal paper solutions.

Our proven methods in manufacturing thermal paper products involve a meticulous approach that combines advanced technology with sustainable practices. By leveraging our extensive experience and state-of-the-art facilities, we guarantee high-quality thermal paper that meets the rigorous demands of printing and packaging processes. Whether you are in retail, logistics, or any other sector that relies on efficient paper products, our commitment to excellence and innovation empowers you to streamline operations and enhance service delivery.

Partnering with Sailing means tapping into a supply chain that prioritizes quality, reliability, and customer satisfaction. As global sourcing becomes increasingly complex, our expertise and agile production capabilities ensure that your business remains competitive and capable of adapting to changing market needs. Join us in exploring the future of thermal paper products and discover how our strategic approach can keep you ahead in the wholesale arena.

Proven Methods To Wholesale How Do They Make Thermal Paper Products Ahead of the Curve

| Method | Description | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| Direct Thermal | Uses heat-sensitive coating to print images and text. | No ink or ribbons required; fast printing speed. | Limited durability; sensitive to heat and light. | Receipts, labels, and tickets. |

| Thermal Transfer | Utilizes a ribbon that transfers ink onto the paper. | Higher print quality; more durable prints. | Requires ink ribbons; slower than direct thermal. | Shipping labels, barcodes, and product labels. |

| Heat Sensitive Coating | Paper coated with materials that change color when heated. | Reliable image quality; similar to direct thermal. | Can be prone to fading over time. | POS systems, medical reports, and tickets. |

| Chemical Coating | Involves the application of special chemicals to paper. | Can offer unique printing options; waterproof variants available. | Higher production complexity; potential health concerns with chemicals. | Specialty labels, high-demand applications. |

| Compounded Thermal Products | Combination of various thermal technologies for enhanced performance. | Versatile usage; high durability and quality. | Research and development may be required. | Diverse applications in logistics and retail. |

Pinpointing Wholesale How Do They Make Thermal Paper Winning in 2025 Factory-Direct Excellence

A

Amelia Young

This purchase was a great decision. The quality is excellent and the service was prompt and professional.

15

May

2025

M

Mason Carter

Exceptional product quality! The after-sales personnel were exemplary in their professionalism.

13

May

2025

L

Layla Martinez

Exceptional product quality! Their support staff was warm and very professional in their approach.

04

June

2025

H

Henry Williams

Top-notch quality! I appreciate how professional and prompt their service team has been.

03

June

2025

O

Olivia Young

Absolutely delighted! The quality is remarkable and the staff was incredibly helpful.

26

May

2025

C

Carter Rivera

Great product! The after-sales service was really efficient and professionally handled.

22

June

2025

Thermal labels

Thermal labels