Custom Wholesale Slitting Label Materials: ODM Solutions, Quotes & Price List

If you require high-quality wholesale slitting label material, you are in the right place. Our slitting label materials are CE certified, ensuring compliance with international safety and quality standards. We recognize the need for reliable products that can handle various applications, which is why we provide a diverse range of options tailored to your needs. As a buyer, finding a dependable supplier who prioritizes quality and consistency is essential. At ShenZhen Sailing Paper Co., Ltd., we offer products with customizable dimensions and finishes, allowing you to easily find the perfect fit. Partnering with us means you gain not just materials, but a commitment to excellence and dedicated customer support. We are here to help enhance your label production and achieve your business goals. Contact us for samples and pricing!

Why Wholesale Slitting Label Material From Concept to Delivery Sets the Industry Standard

In the ever-evolving landscape of the printing and packaging industry, the demand for high-quality slitting label materials has never been more crucial. Since 2011, Sailing has emerged from a local paper converter to a leading international group company with production facilities in both China and Malaysia. Our commitment to excellence in every phase of production positions us as a benchmark in the industry. We specialize in the production and export of printing, packaging, and logistic consumables, ensuring that we meet the diverse needs of our global clientele.

The journey from concept to delivery is meticulously crafted at Sailing. Our state-of-the-art facilities employ advanced slitting technology, ensuring precise cuts that meet the specifications of varied applications. This attention to detail not only enhances the performance of label materials but also reduces waste, making our products a sustainable choice for businesses worldwide. Our dedicated R&D team works closely with clients to tailor solutions that not only adhere to their requirements but also push the boundaries of innovation.

Choosing Sailing means partnering with a company that understands the intricacies of global supply chains. Our streamlined logistics and quality assurance protocols ensure timely delivery of products, allowing our clients to maintain their production schedules without disruption. By consistently providing reliable and high-quality materials, Sailing has set a standard that resonates with clients looking for excellence in the wholesale slitting label material market. We invite global procurers to experience the Sailing difference, where quality meets commitment at every step of the process.

Why Wholesale Slitting Label Material From Concept to Delivery Sets the Industry Standard

| Feature | Description | Standardization Metric |

|---|---|---|

| Material Quality | High-grade materials ensure durability and print quality. | ISO 9001 Certified |

| Customization Options | Multiple sizes, finishes, and adhesive types to meet diverse needs. | 99% Customer Satisfaction Rate |

| Lead Time | Efficient production processes result in fast turnaround times. | Average 5-day lead time |

| Eco-friendliness | Utilization of sustainable practices and materials. | Certified by Environmental Standards (ES) |

| Technical Support | Dedicated team available for support and consultations. | 24/7 Support Availability |

How Chinese Manufacturers Wholesale Slitting Label Material Outperforms the Competition Is The Best

E

Emma Johnson

Excellent craftsmanship! I truly appreciate the prompt and professional service from the support team.

14

June

2025

Z

Zoe Mitchell

I love this product! The support team showed great understanding and professionalism throughout.

24

June

2025

B

Ben Lewis

Quality was better than I imagined! The after-sales service was responsive and extremely professional.

06

June

2025

C

Chloe Hill

Highly satisfied with my order! The after-sales service was professional and prompt.

19

June

2025

Z

Zoe Gonzalez

Absolutely outstanding! The quality of the product and the service were both exemplary.

16

May

2025

S

Sophia Adams

Absolutely satisfied! The product quality matched my expectations, and the service was very personalized.

11

May

2025

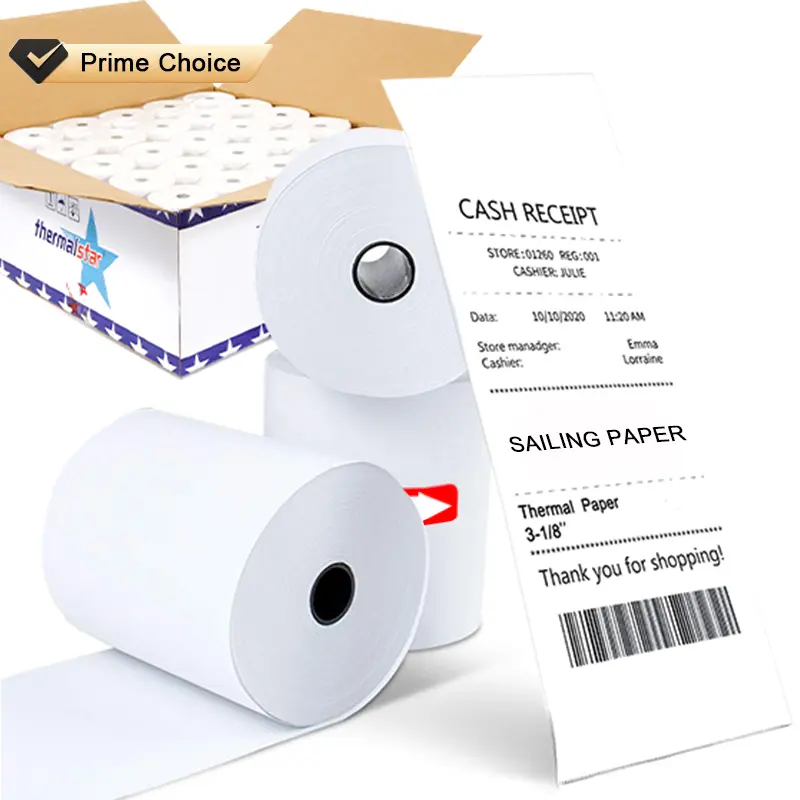

Thermal labels

Thermal labels